Brock, Vince, Dave (Steamer), George, & Nick

Wow! Thanks guys for all the great support; it really means a lot to me, especially from some of our most talented members.

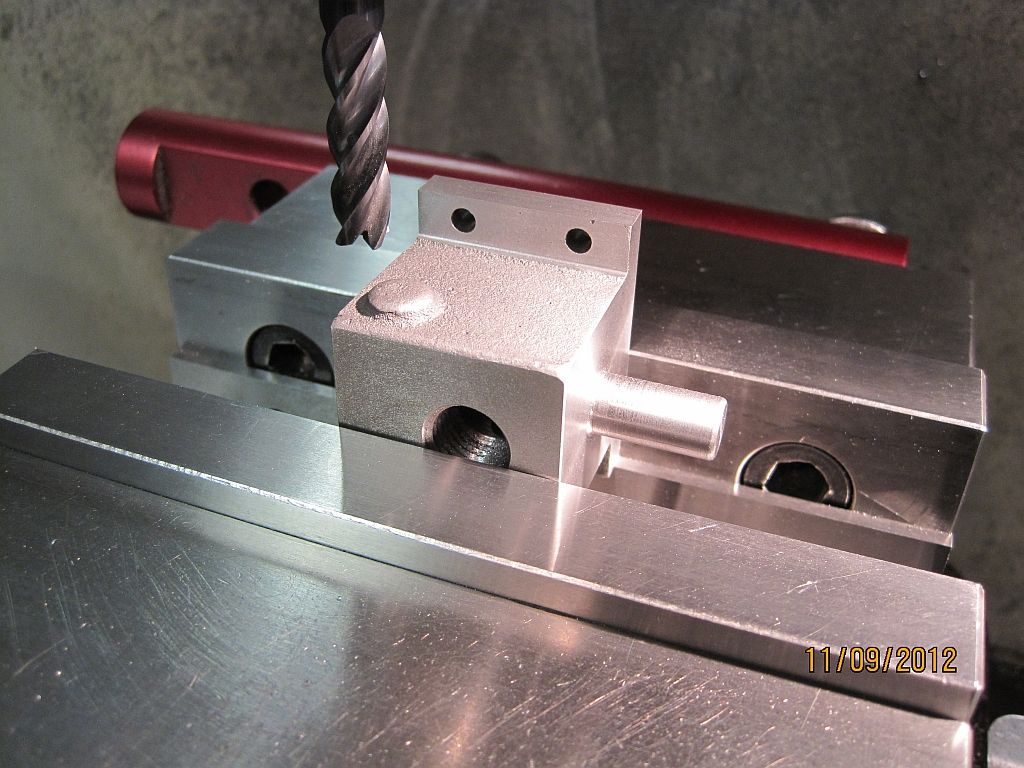

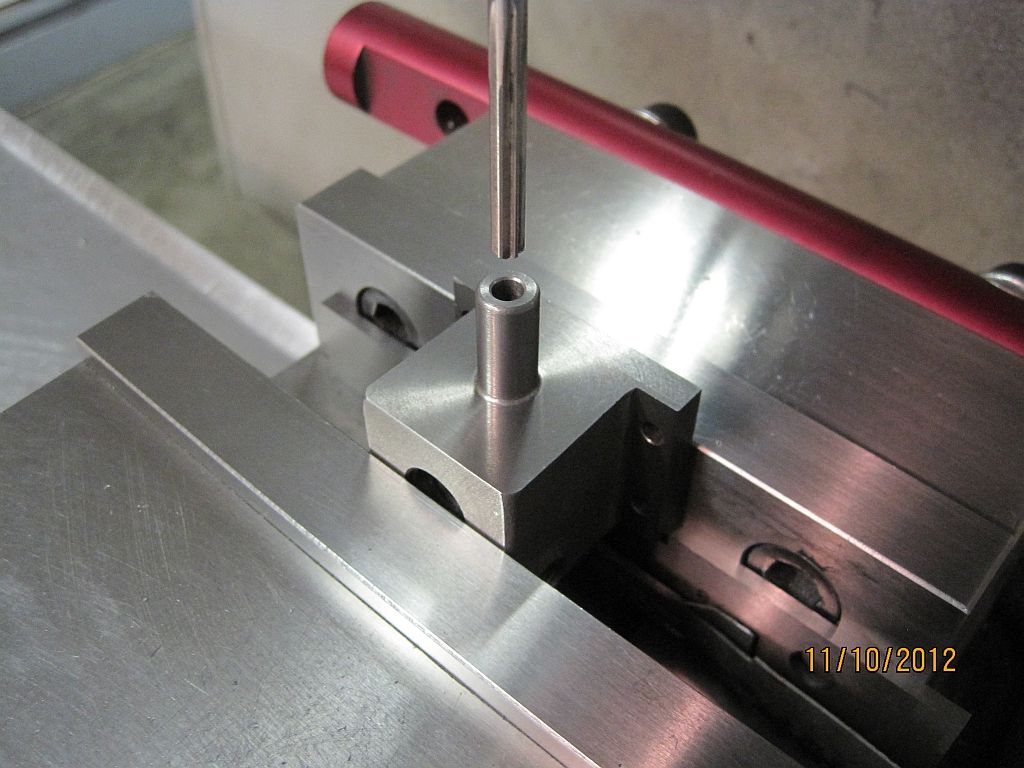

With regards to the lettering on the grease cups; here is a picture of what I am trying to do. I really want to do this myself and having access to CNC mill both at work and home it should be doable.

What I’m trying to determine is the best type of cutter. I have some good information from an acquaintance on how to grind a cutter on the Deckel SO grinder that will work. So this may be the first try.

I have also been looking at the diamond drag engravers on eBay; they are only about $70.00 so this is also a possibility.

I will do the CAD work on the letters and most likely do the engraving on my Fadal mill at work. I will keep you guys posted on the outcome.

George I think I’m familiar with the type of photo etching you are referring to. I have also done some name plate etching for full sized engines and a couple of models using ferric chloride and a laser printed mask. This may be a possibility but I think I want to give engraving a try.

Dave; the Weiler is my pride and joy. I was able to purchase it from a local machinery dealer here in town. It came from my employer and due to some consolidation they were getting rid of a bunch of machinery and tooling; I purchased 18 or so years ago.

It went from the plant directly to my garage. It was purchased new by my employer for the tool and die shop so I’m the second owner. After moving out of the tool shop it spent some time in one of the maintenance departments where I happened to be working at the time. I replaced the cross feed screw and nuts during that time; these parts cost more than most HSM guys spend on a whole new lathe. I glad I didn’t have to by them out of my own pocket.

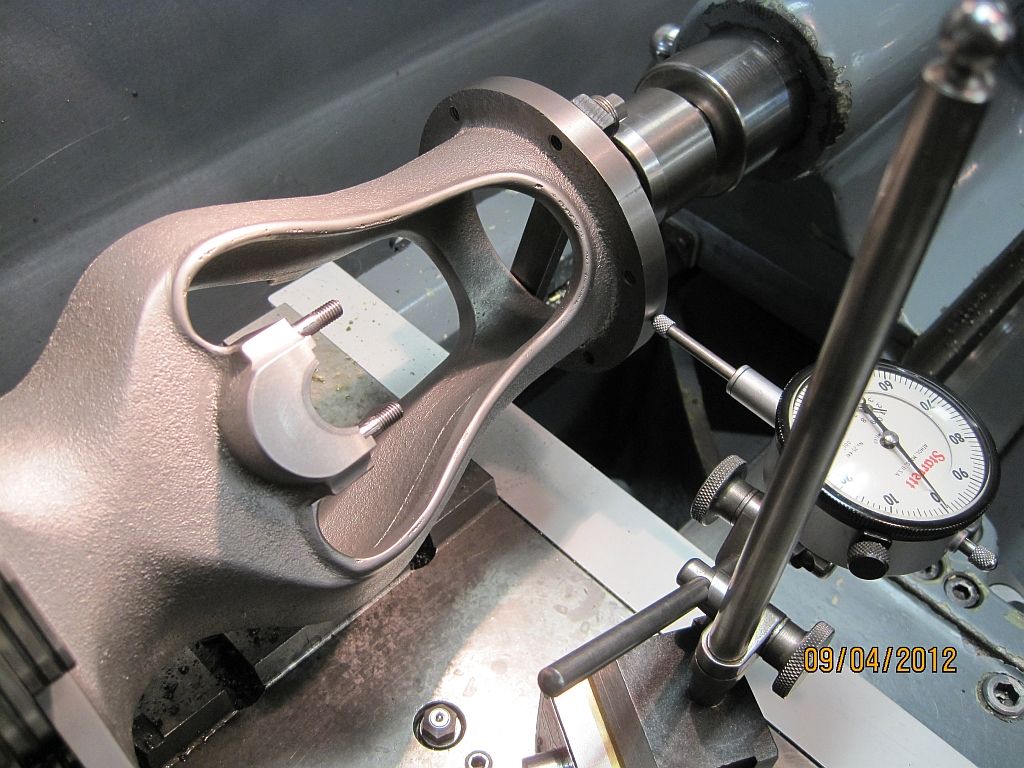

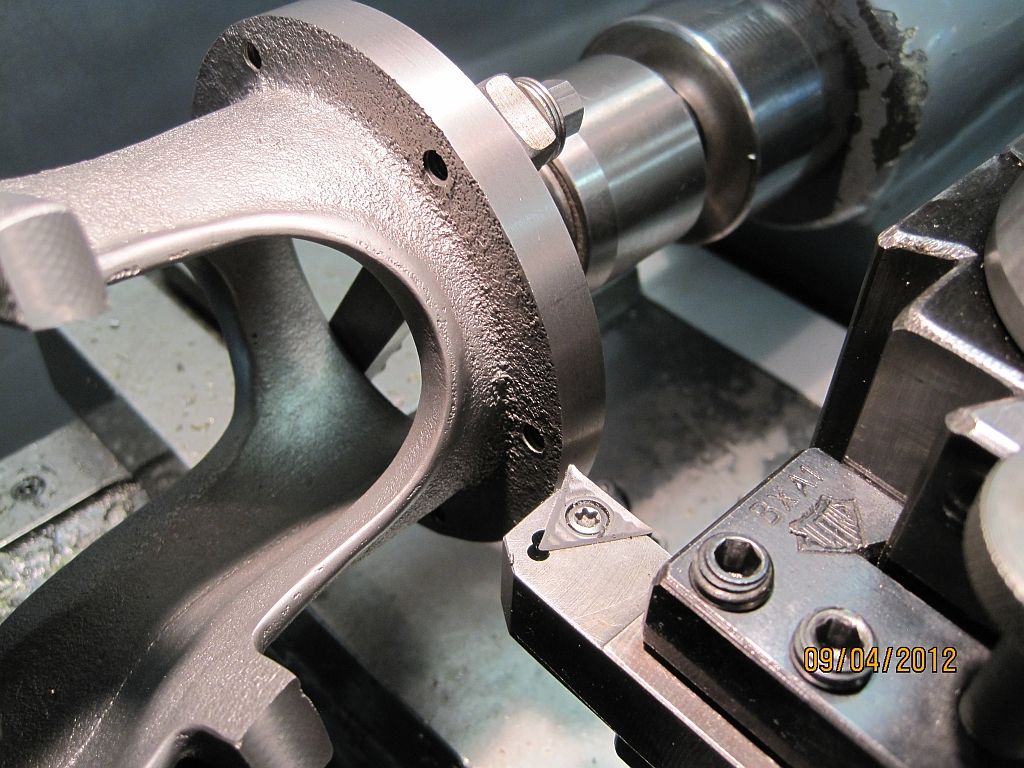

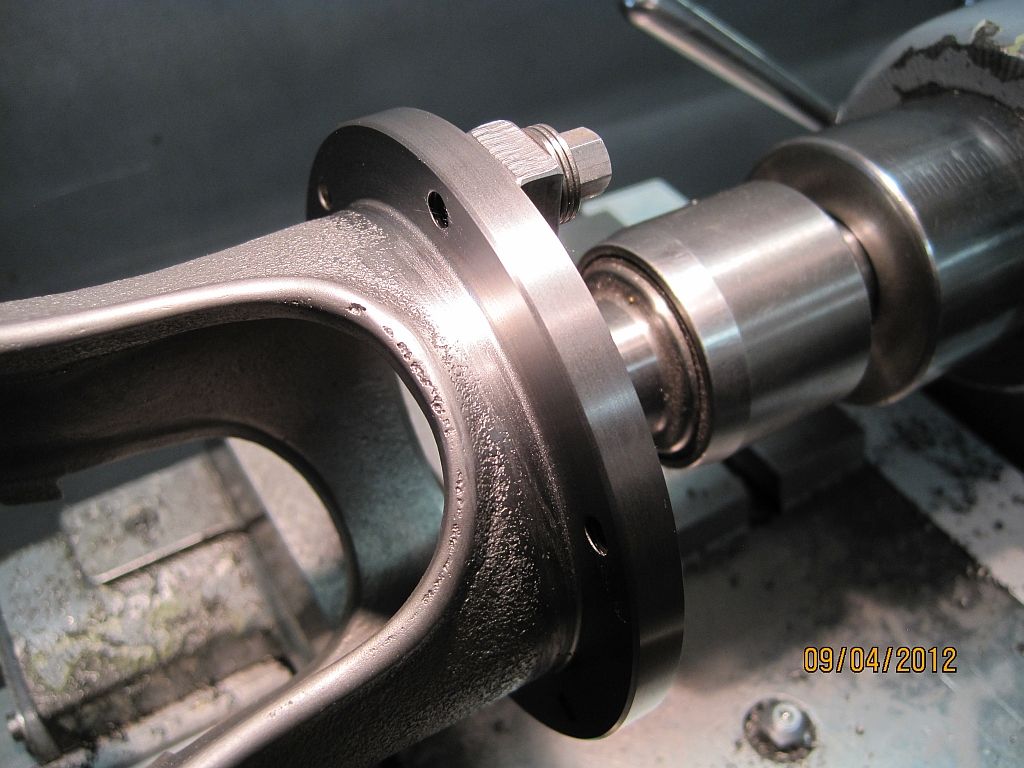

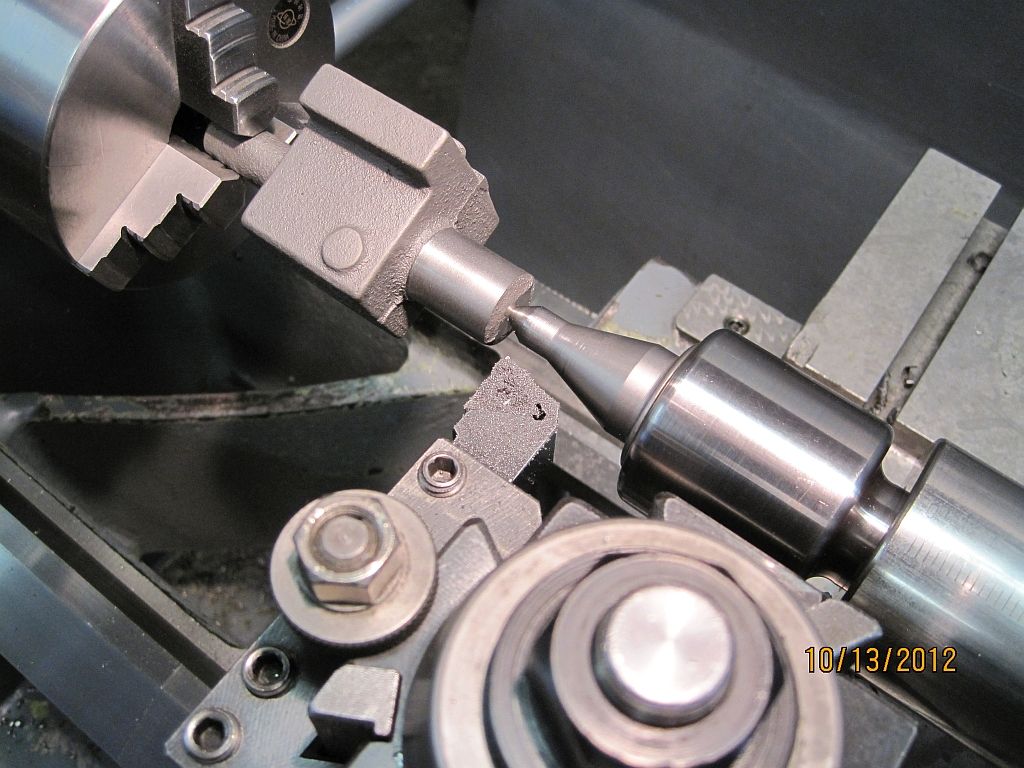

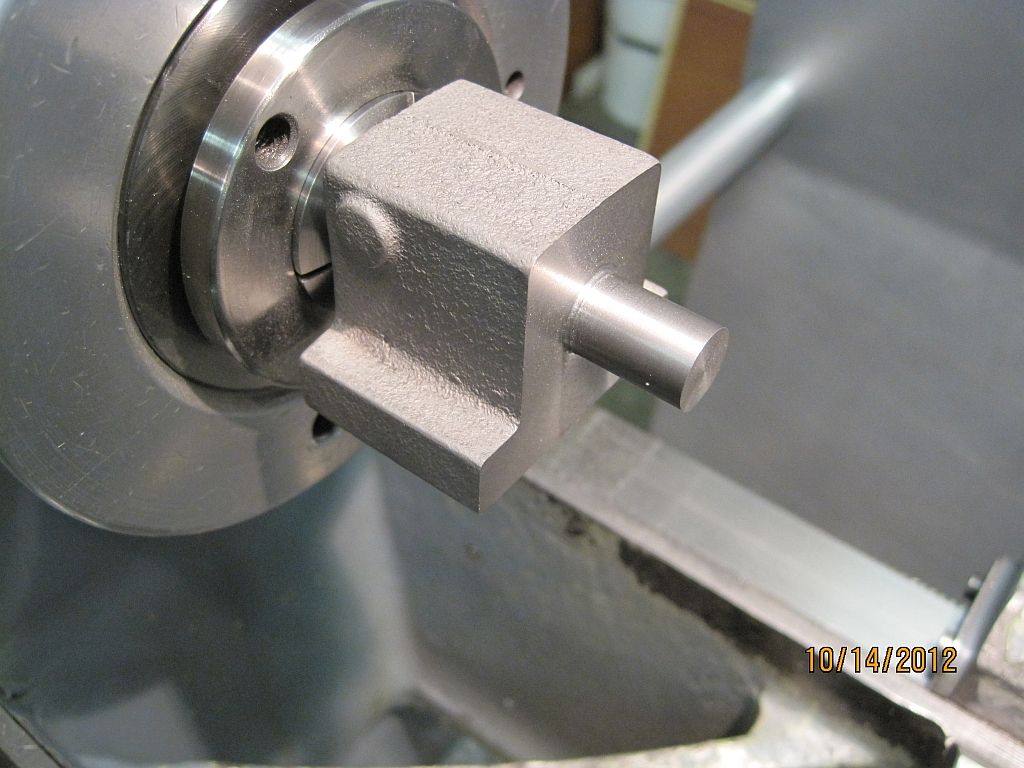

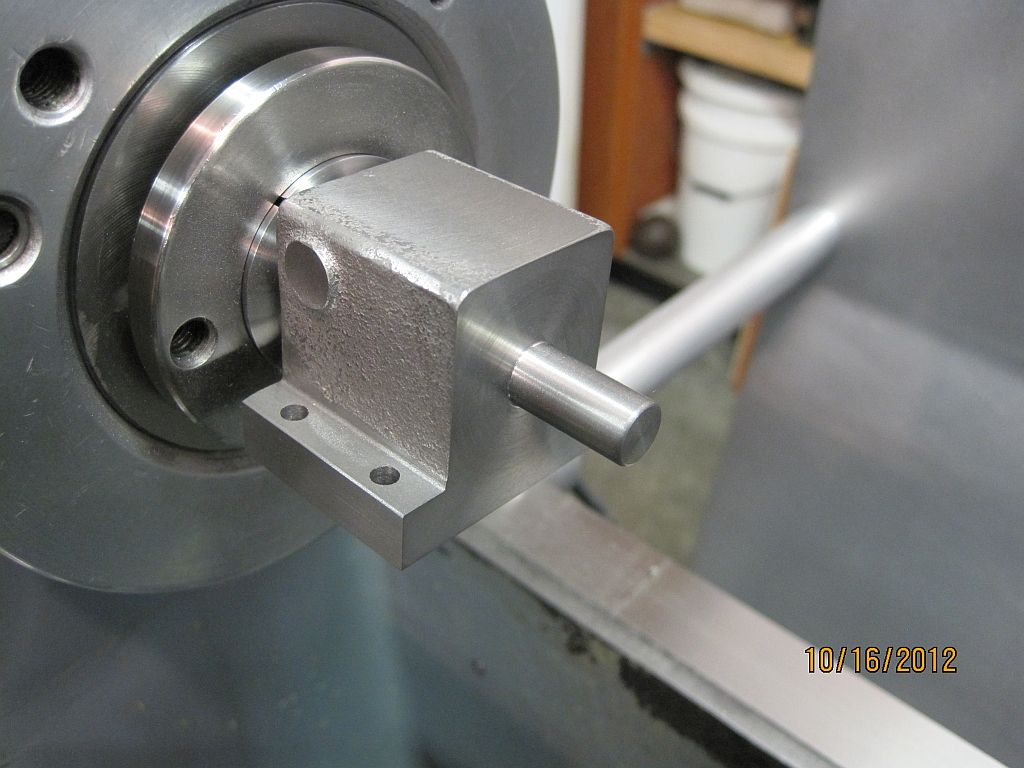

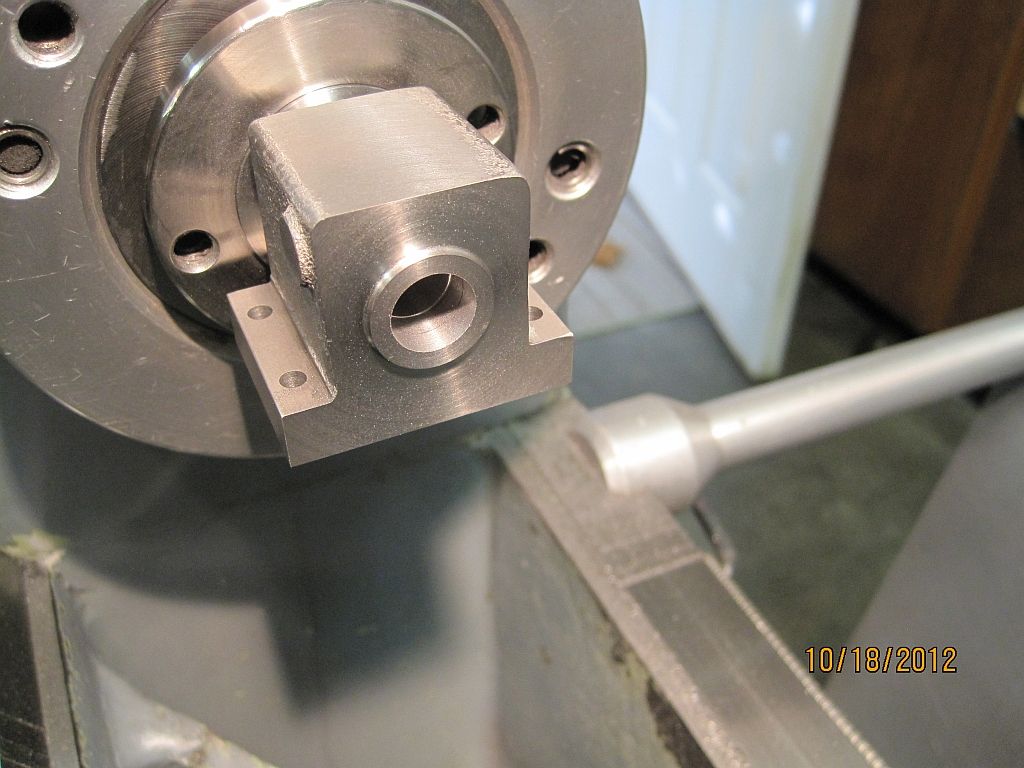

One strange thing is there was no follow rest or steady rest purchased with the lathe. I purchased one on eBay that would work and re-machined the base to fit the Weiler.

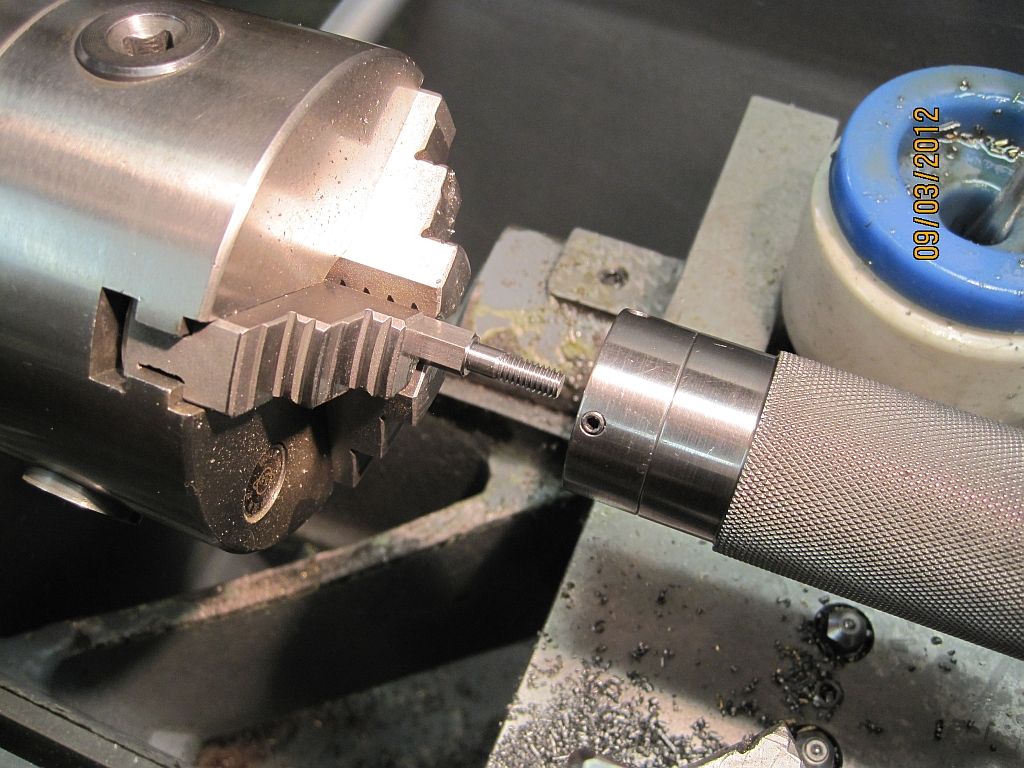

I have sense purchased the proper steady from a guy over on the PM web site. Also because the 3 jaw was huge 8” a few years back I purchased 3 & 6 jaw Bison chucks both in 6” size. The back plates had to be machined by me because of the funky DIN spindle nose.

It is a relatively rigid machine and will happily remove .2” from the diameter of aluminum or leaded steel stock.

Funny story; I started working in the Model Shop at work (R&D machine shop) about a year and a half ago; this is a small shop with only 5 of us. One day, one of my coworkers and I were digging through a small cabinet looking for something when we found,-------the carriage stop for my Weiler! Boy was I happy with that; it even had the matching serial number stamped on it.

Ok I will quit rambling now; But thanks again guys for all your kind words; it makes my day.

Dave