Here's how the freshly oiled and cleaned light ten looks at this point.

I will post some photos of how we got here in a later post.

I wanted the cabinet darker and the lathe more towards the beige, but I don't give a rat's a$& .

.

Leveled and set in it's permanent place...

Another look.

This is the variable frequency drive that handles the 1/2 HP 3 phase motor:

I hooked it up temporarily, but never got to making the nice controls I meant to make...

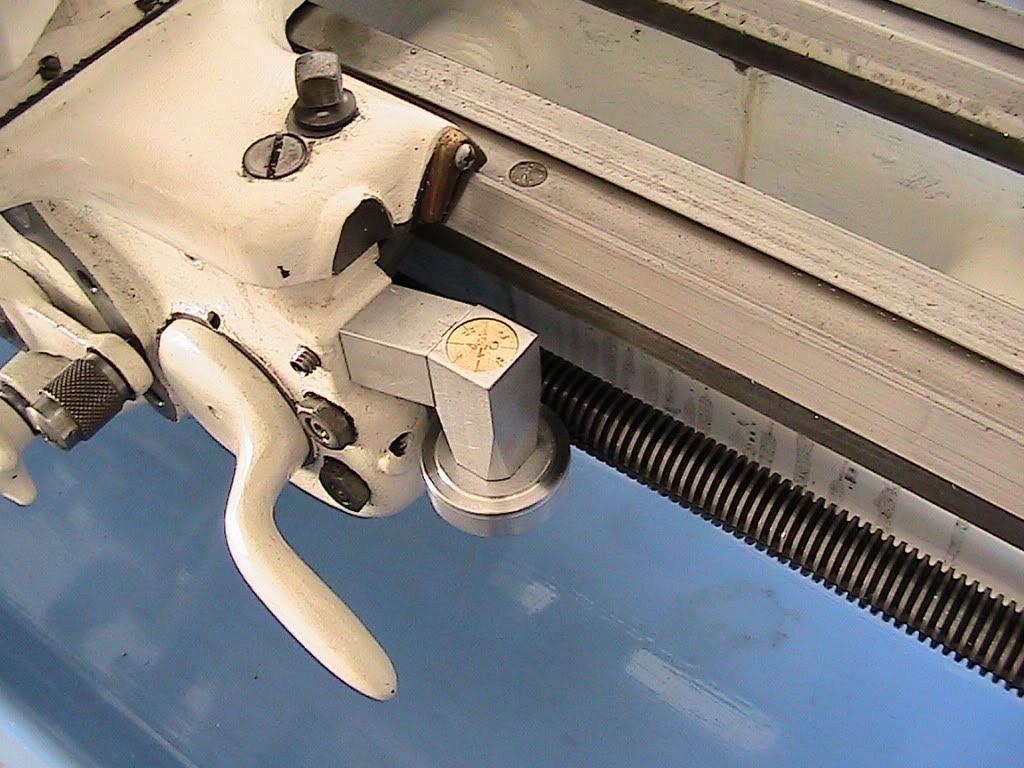

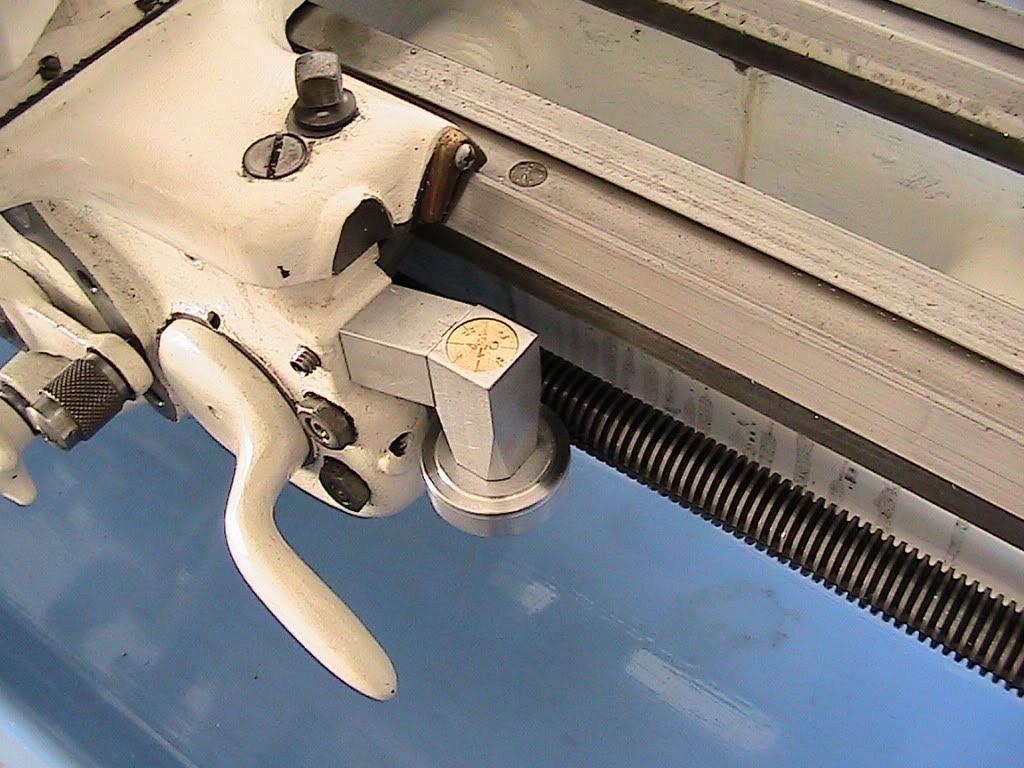

This is a carriage stop and a holder for a 2 inch travel dial indicator.

And this is the home brewed threading dial. It awaits painting of the engravings (Lacquer Stick -- it's in the mail -- thanks for the pointer Gail in NM)... I should also change the setscrew to a shorter brass-tipped one... Oh, well, temporarily it'll do (will be there next year :big

What I absolutely hate is the lantern style tool post.

Which is going to change to an under construction piston style quick change tool post... Here's the body. I stopped the boring operations as I was getting tons of chatter, and I decided to make a decent boring bar and a decent boring bar holder. When I do, I'll resume construction...

take care,

tom in MA

I will post some photos of how we got here in a later post.

I wanted the cabinet darker and the lathe more towards the beige, but I don't give a rat's a$&

Leveled and set in it's permanent place...

Another look.

This is the variable frequency drive that handles the 1/2 HP 3 phase motor:

I hooked it up temporarily, but never got to making the nice controls I meant to make...

This is a carriage stop and a holder for a 2 inch travel dial indicator.

And this is the home brewed threading dial. It awaits painting of the engravings (Lacquer Stick -- it's in the mail -- thanks for the pointer Gail in NM)... I should also change the setscrew to a shorter brass-tipped one... Oh, well, temporarily it'll do (will be there next year :big

What I absolutely hate is the lantern style tool post.

Which is going to change to an under construction piston style quick change tool post... Here's the body. I stopped the boring operations as I was getting tons of chatter, and I decided to make a decent boring bar and a decent boring bar holder. When I do, I'll resume construction...

take care,

tom in MA