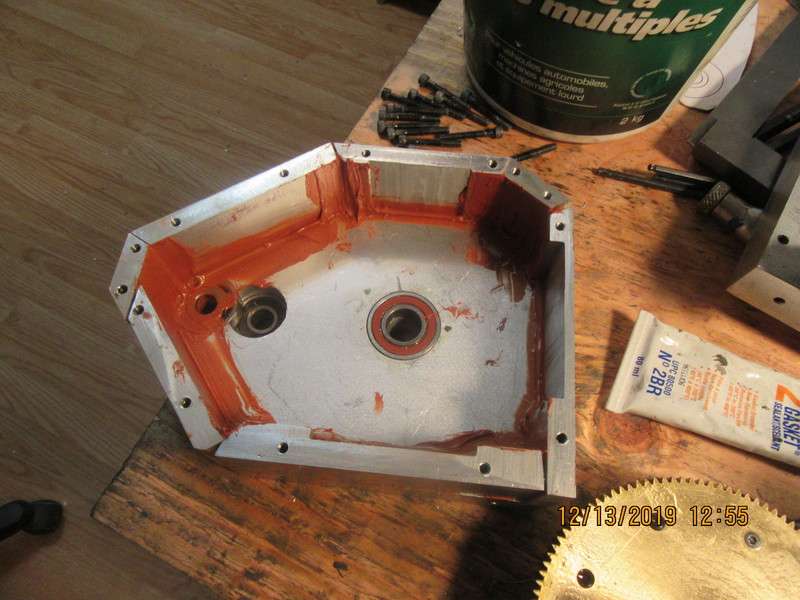

Beautiful gears! I assume the larger one is keyed onto the shaft with the integral smaller gear?

With regard to the large brass gear - are you using brass for wear purposes? Wonder what a piece of phenolic or delrin or such would cost - I would think either would be cheaper than brass, but I haven't actually tried to source either in the size / shape needed for a gear blank.

I too have a large-ish plate of brass, close to 1/2" thick in my case, with some odds and ends of holes in it from its previous life. Every time I come to something that could use a large piece of brass, I find myself hesitating - is *this* the project I want to use this on? What if I use it now, and then *really* need it later on? Based on the history thus far, I'm guessing this piece of brass might be buried with me!

With regard to the sanding strips - I woulda thunk that 120 grit would get you there within a reasonable length of time. Are you using cutting oil with the strips? Especially, are you regularly floating off the build-up of swarf?

What I use are billed as "emery cloth" - don't know if that is any different from the carborundum strips you are using ...