Harold Lee

Well-Known Member

- Joined

- Apr 23, 2008

- Messages

- 236

- Reaction score

- 2

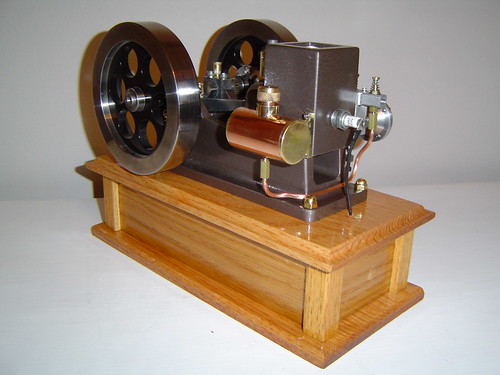

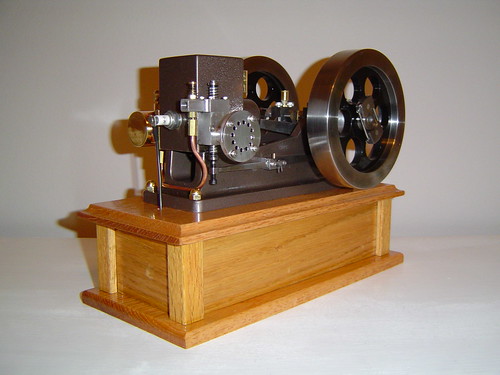

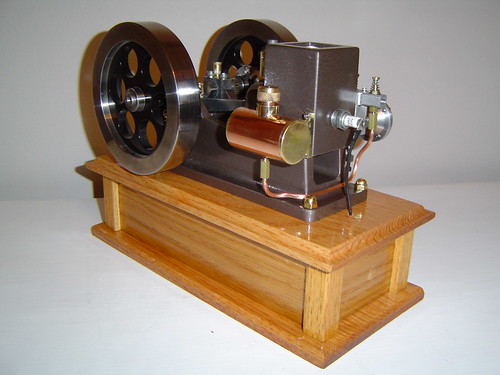

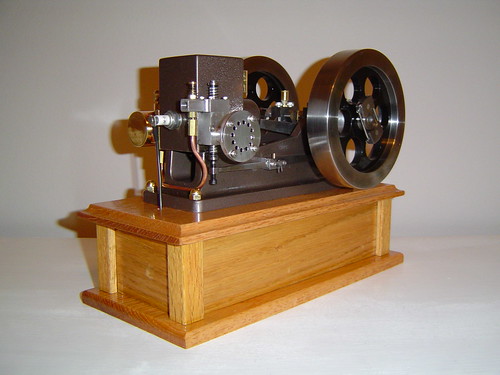

I completed this engine in February and gave it to my 5 year old grandson. He calls it "Old Bessie".

This was designed by the late Philip Duclos and was published in Home Shop Machinist in 1987. The

plans are in his book "The Shop Wisdom of Philip Duclos" This is a very sweet running engine.

I am currently building two more...

[youtube=425,350]<object width="425" height="355"><param name="movie" value="http://www.youtube.com/v/-x1yxKnYLEA&hl=en"></param><param name="wmode" value="transparent"></param><embed src="http://www.youtube.com/v/-x1yxKnYLEA&hl=en" type="application/x-shockwave-flash" wmode="transparent" width="425" height="355"></embed></object>[/youtube]

This was designed by the late Philip Duclos and was published in Home Shop Machinist in 1987. The

plans are in his book "The Shop Wisdom of Philip Duclos" This is a very sweet running engine.

I am currently building two more...

[youtube=425,350]<object width="425" height="355"><param name="movie" value="http://www.youtube.com/v/-x1yxKnYLEA&hl=en"></param><param name="wmode" value="transparent"></param><embed src="http://www.youtube.com/v/-x1yxKnYLEA&hl=en" type="application/x-shockwave-flash" wmode="transparent" width="425" height="355"></embed></object>[/youtube]