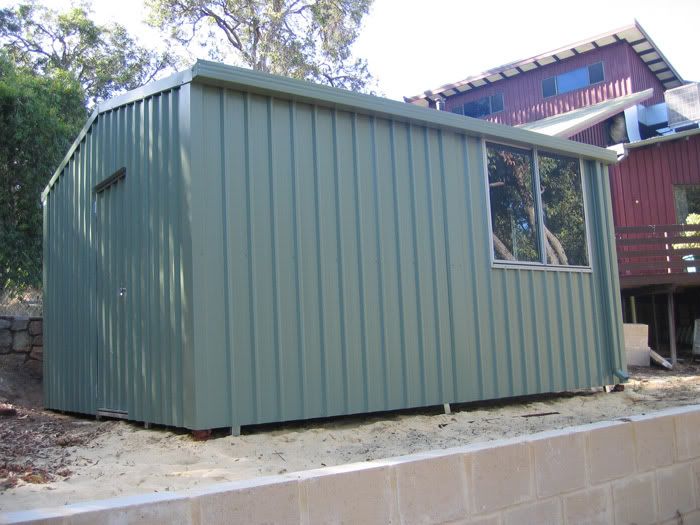

Building my workshop has been a long process with it being finished just last weekend.

Well the inside finished, I still have paving and some other stuff to do outside.

I'll give you all a quick photo show of the process.

I had a 3m by 3m shed that had to go to build my workshop.

I built a 2.4 by 2.4m shed elsewhere and then knocked this down.

Going

Gone

I then needed just a small amount of earth works done to level the ground for my larger workshop

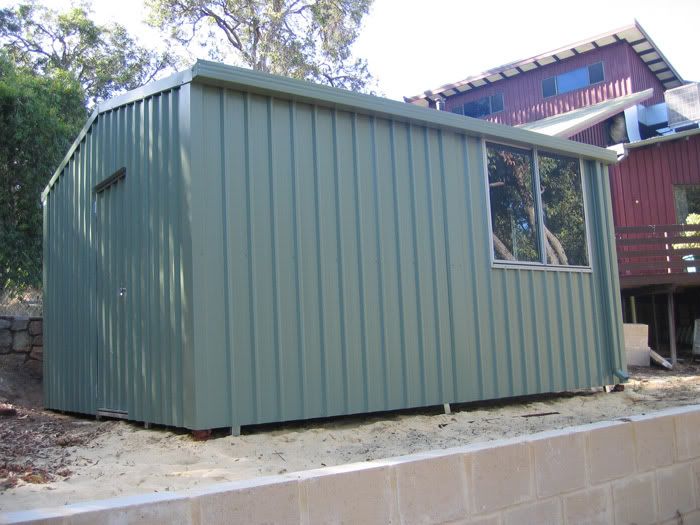

After just getting a few wheel barrows of dirt carried down I had some level ground and after a few weeks I got my council approval and had my workshop delivered.

It only took a day to go up

You will notice no floor yet, got that poured after it went up as doing it that way helps to seal the workshop to the floor to stop water leaks.

No floor

Floor

I have a great view out of my window in the workshop

Just started to move my gear in.

This is the storage corner.

The small bench is now cleared of my material and is actually made of stainless steel with a 3/4 inch chopping block for a top as it was a freebie from a butcher that was getting refitted.

The empty space below the window is reserved for my main work bench

My drill and buffing machine setup.

The space where my toolbox and drop saw is sitting is where my lathe will go

Thats about where I am at, at the moment, just need to get my lathe and a new bench grinder and I'm good to go. ;D

Well the inside finished, I still have paving and some other stuff to do outside.

I'll give you all a quick photo show of the process.

I had a 3m by 3m shed that had to go to build my workshop.

I built a 2.4 by 2.4m shed elsewhere and then knocked this down.

Going

Gone

I then needed just a small amount of earth works done to level the ground for my larger workshop

After just getting a few wheel barrows of dirt carried down I had some level ground and after a few weeks I got my council approval and had my workshop delivered.

It only took a day to go up

You will notice no floor yet, got that poured after it went up as doing it that way helps to seal the workshop to the floor to stop water leaks.

No floor

Floor

I have a great view out of my window in the workshop

Just started to move my gear in.

This is the storage corner.

The small bench is now cleared of my material and is actually made of stainless steel with a 3/4 inch chopping block for a top as it was a freebie from a butcher that was getting refitted.

The empty space below the window is reserved for my main work bench

My drill and buffing machine setup.

The space where my toolbox and drop saw is sitting is where my lathe will go

Thats about where I am at, at the moment, just need to get my lathe and a new bench grinder and I'm good to go. ;D