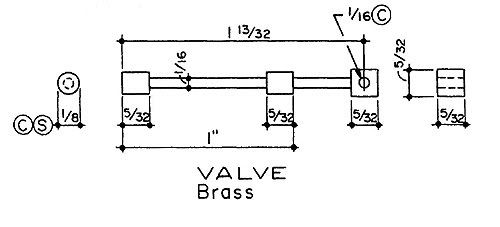

It took me 4 attempts to make that valve.

The first two broke early in the turning process because I had mistaken

a piece of thin bronze for brass.

After I found a piece of brass in the materials box the third one cut great.

Until... I got greedy and tried to take too much of a cut. :

Turning the stock down from 1/8" to 1/16" would probably be more difficult

using steel.

For me, a perfectly centered narrow parting tool worked best for the 1/16"

undercut areas. I kept the work very close to the chuck and cut it about 1/4"

at a time. Then I'd slide the stock out a little farther and cut back another 1/4"

until the center widths were finished.

Hopefully we will see some other suggestions here on better ways to cut that part.

For anyone who is not familiar with it, this is the part to be made.

Rick