You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My own Engine

- Thread starter Paolo

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

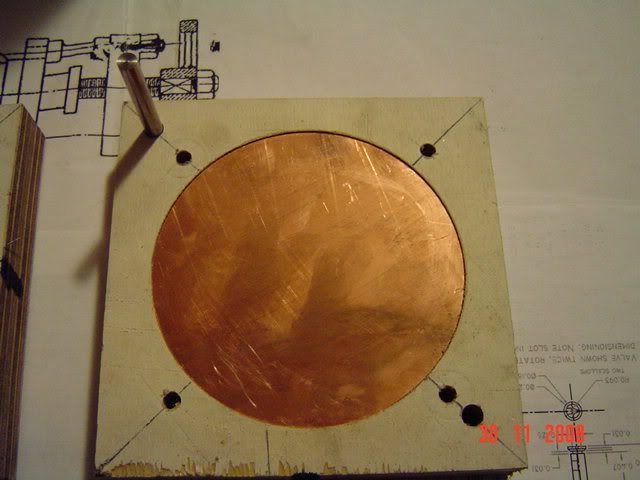

And now..Boiler time.!! I decided for the vertical by SandyC. I decided to make a die and punch and press the discs into shape as others did. I used Plexiglas for the punch and pressed wood for the die...

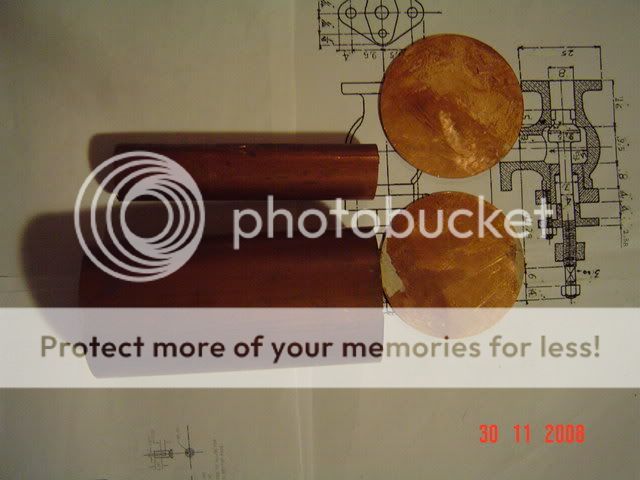

Raw material

http://The punch&die just done!!

http://The punch&die just done!!

http://i268.photobucket.com/albums/jj19/Mauro1952/SM1-Engine/DSC01568.jpg

Disc test....

...and few hours later..final results!!!

Thanks firebird for sharing your idea!!!

Raw material

http://i268.photobucket.com/albums/jj19/Mauro1952/SM1-Engine/DSC01568.jpg

Disc test....

...and few hours later..final results!!!

Thanks firebird for sharing your idea!!!

We learn all times...I received a message by SandyC :bow: :bow: :bow: plenty of suggestions...That was I did for avoiding heat dispersion and I decided to use a bigger jet nozzle on my welding station...

after that I started the second silver soldering session...that is the final result...Thanks again SandyC!!

I decided to do some replenishment on the top...not so elegant, for the moment, but well done

after that I started the second silver soldering session...that is the final result...Thanks again SandyC!!

I decided to do some replenishment on the top...not so elegant, for the moment, but well done

Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

Nice work Paolo. I had trouble with silver soldering when I first attempted it. I was using a portable propane torch...just enough heat to get myself in trouble. I learned since that time you need a lot of heat especially on large parts. Your experience is another confirmation of that. Good luck finishing up :bow:

Cheers,

Phil

Cheers,

Phil

Thanks Maryak...Please Try one....this is my second ,the first was much simple and little, I had a big support from SandyC...and I was able to overcome the initial fault...I have seen your nice engine :bow:...so I bet you have ALL knowhow for doing a boiler...

Cheers Paolo

PS: Yesterday evening I started the funnel ancillaries...when..my late..died after a lots of electrical bang :-[ :-[ :-[

After that, waiting for some spare parts, I'm doing a little clean and touch on my boiler..It seams to be OK now...

Cheers Paolo

PS: Yesterday evening I started the funnel ancillaries...when..my late..died after a lots of electrical bang :-[ :-[ :-[

After that, waiting for some spare parts, I'm doing a little clean and touch on my boiler..It seams to be OK now...

K

Kermit

Guest

shred said:I must find my 'first silver-soldering' test part. It's a very ugly thing. By the 3rd or 4th joint I was starting to get the hang of it. ;D

I did my first solder joint with my mothers (brand new at the time) woodburning set.

LOTS of things got hot that day!

Paolo said:Just received...Raw material for burners....

Uhmm, whats inside the white boxes?? I gotta know!

Divided He ad

Well-Known Member

- Joined

- Mar 21, 2008

- Messages

- 549

- Reaction score

- 2

I think they are ceramic plates not boxes!

I'm thinking an interesting burner build could be on the way?

Nice work on the boiler Paolo, Have you had chance to do any more over the holidays or are you taking the full family time?

Looking forward to the next part as usual ;D

Ralph.

I'm thinking an interesting burner build could be on the way?

Nice work on the boiler Paolo, Have you had chance to do any more over the holidays or are you taking the full family time?

Looking forward to the next part as usual ;D

Ralph.

Hi T70MkIII I went to my country house ...so i stopped a little doing others "hobbies".... :big:

Hi Ralph...no I wasn't able to do anything because my late was broken...

I received the electronic card repaired just yesterday..BUT...I have to change the motor...It seames to be "over heated" but I was able to start the burner body and finished the funnel ancillaries,as You can see, working at low speed...

I received the electronic card repaired just yesterday..BUT...I have to change the motor...It seames to be "over heated" but I was able to start the burner body and finished the funnel ancillaries,as You can see, working at low speed...

Hi Kermit the white box are ceramics plate received from an Italian factory at very low price... :big: :big: :big:

Cheers

Hi Ralph...no I wasn't able to do anything because my late was broken...

Hi Kermit the white box are ceramics plate received from an Italian factory at very low price... :big: :big: :big:

Cheers

Similar threads

- Replies

- 107

- Views

- 7K

- Replies

- 25

- Views

- 3K