student_Machinist

Feist92

- Joined

- Jan 19, 2008

- Messages

- 86

- Reaction score

- 4

Hey guys

I know this isnt really the focus of this forum but someone might find it interesting, that and i need as much help as i can get

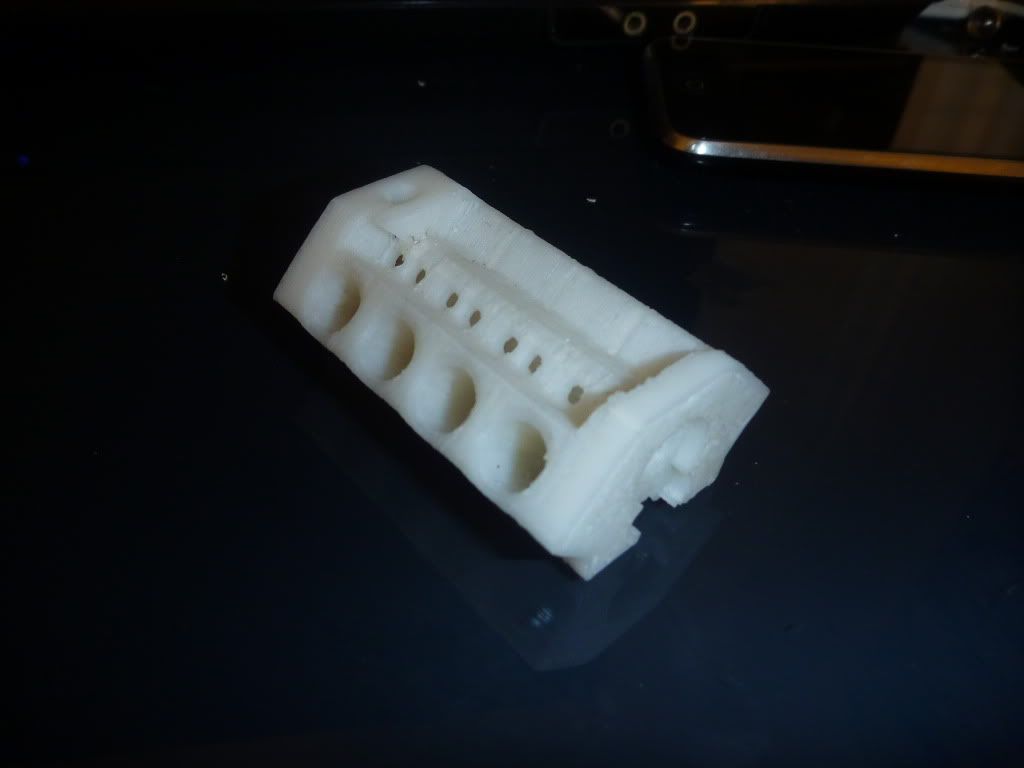

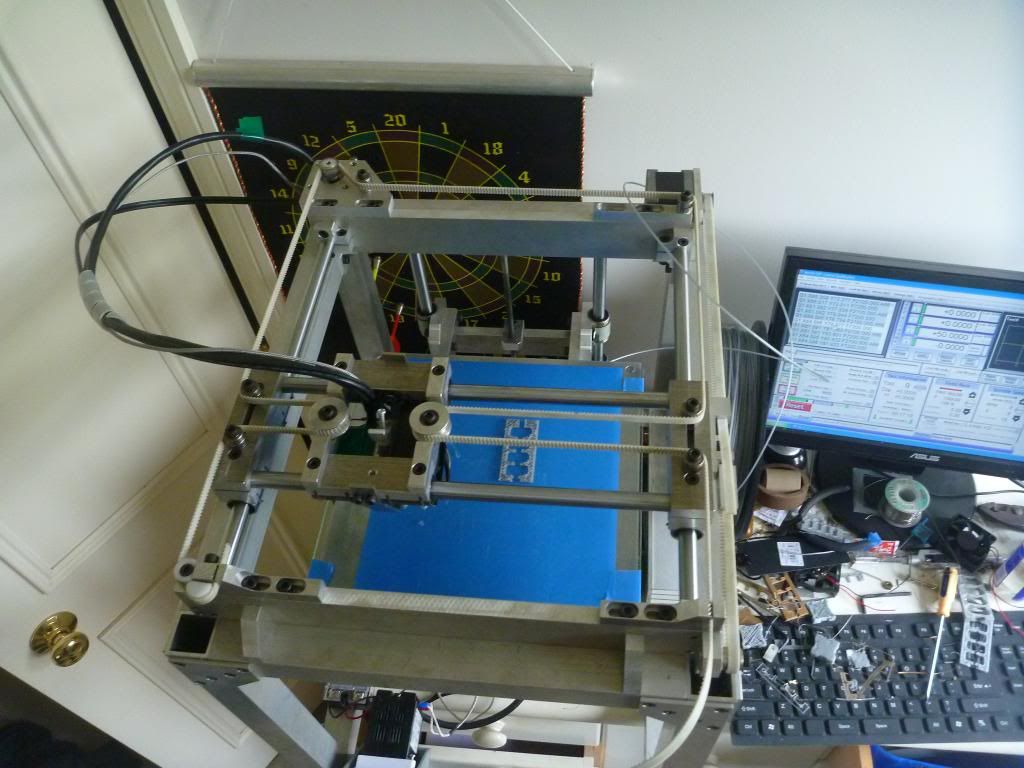

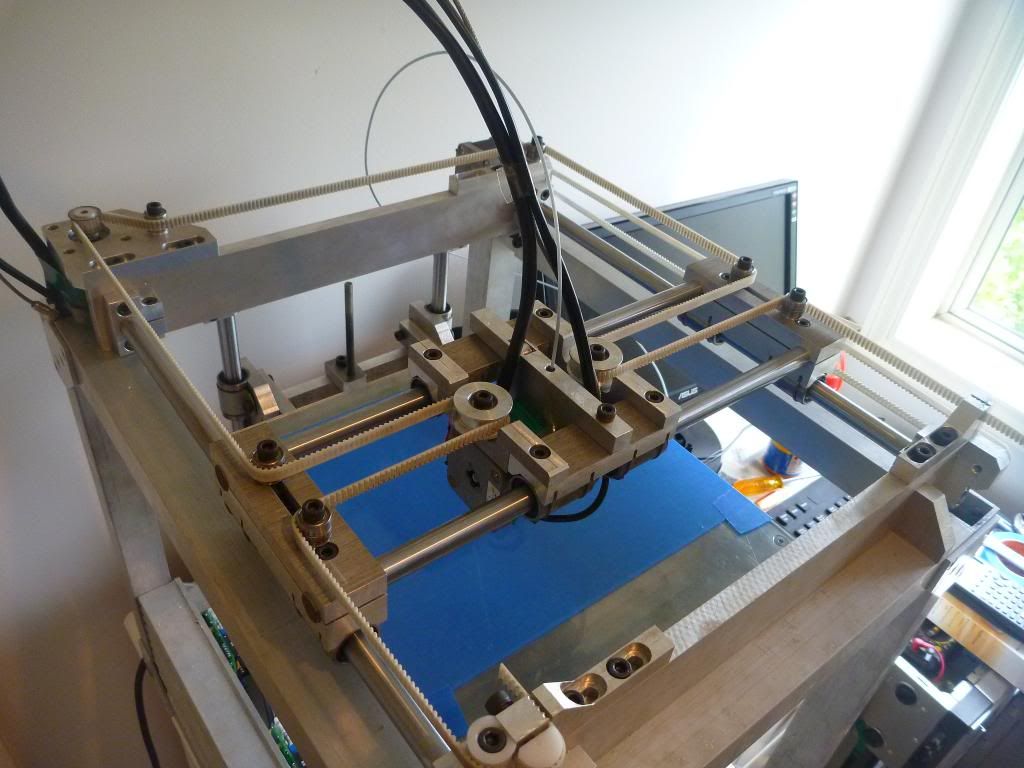

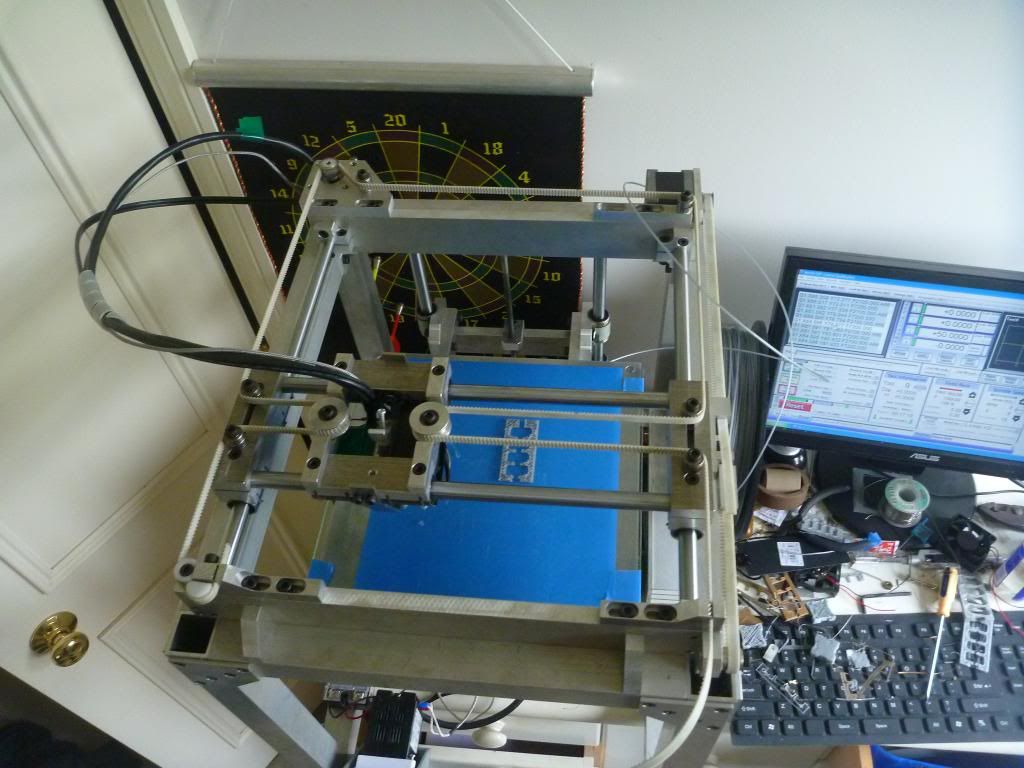

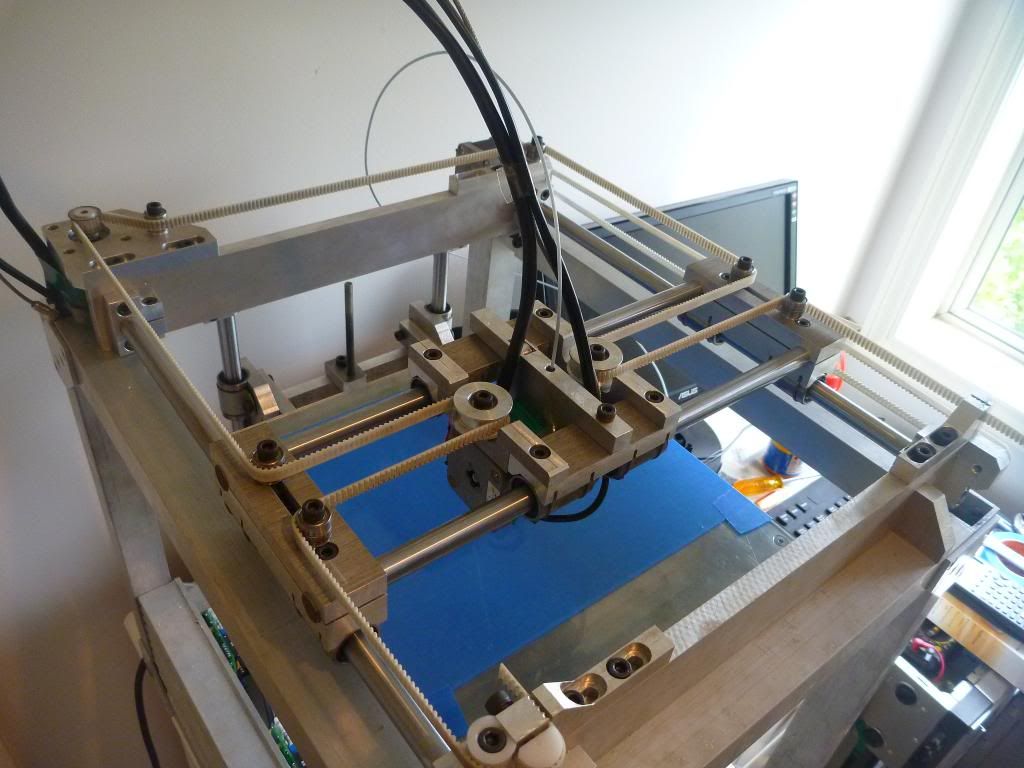

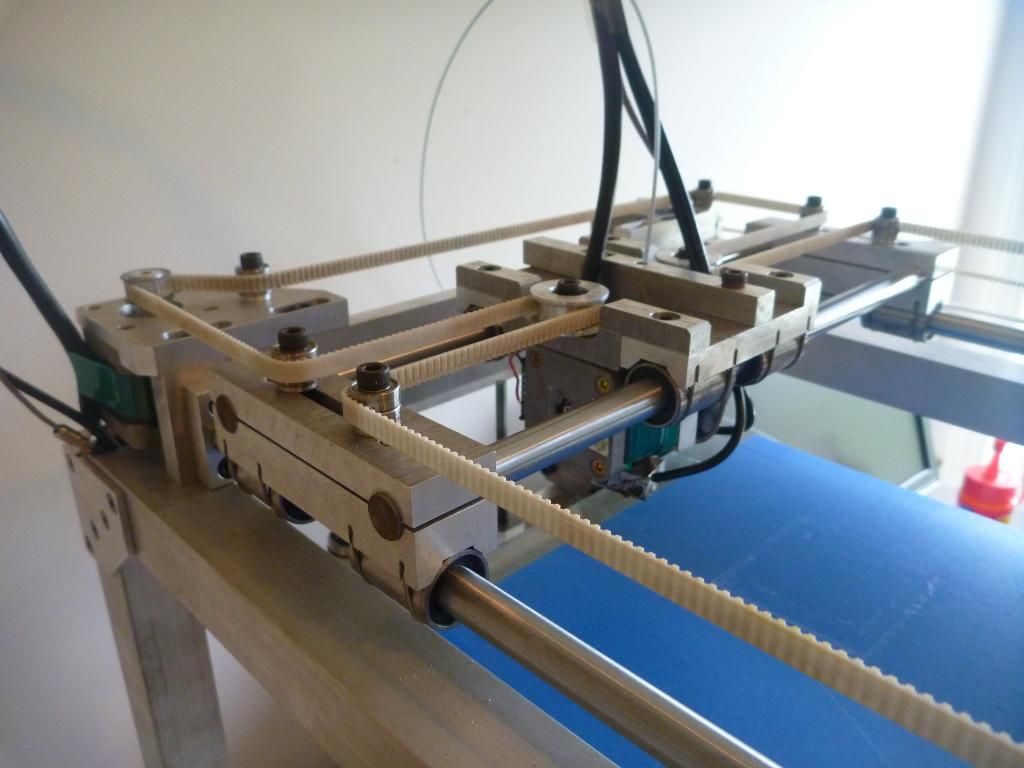

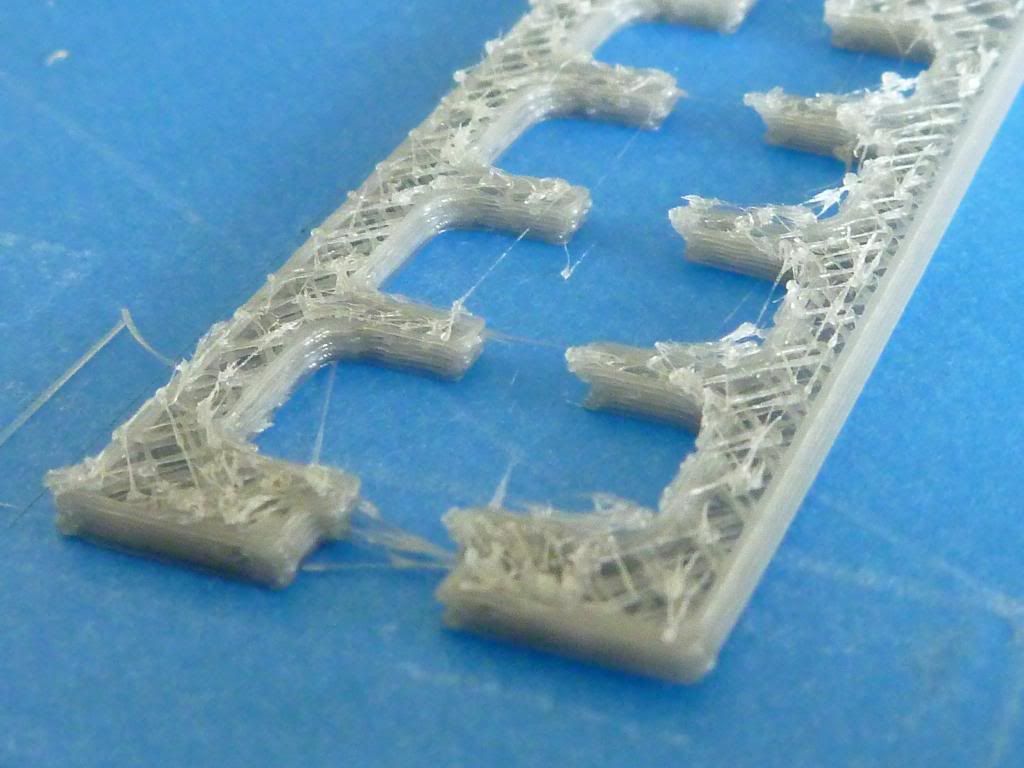

I started this printer when i was 18 (im 19 almost 20 now) and its been complete for quite some time but ive been messing around with a massive issue for the past 10 months that ive never been able to get past. But first here are the pics

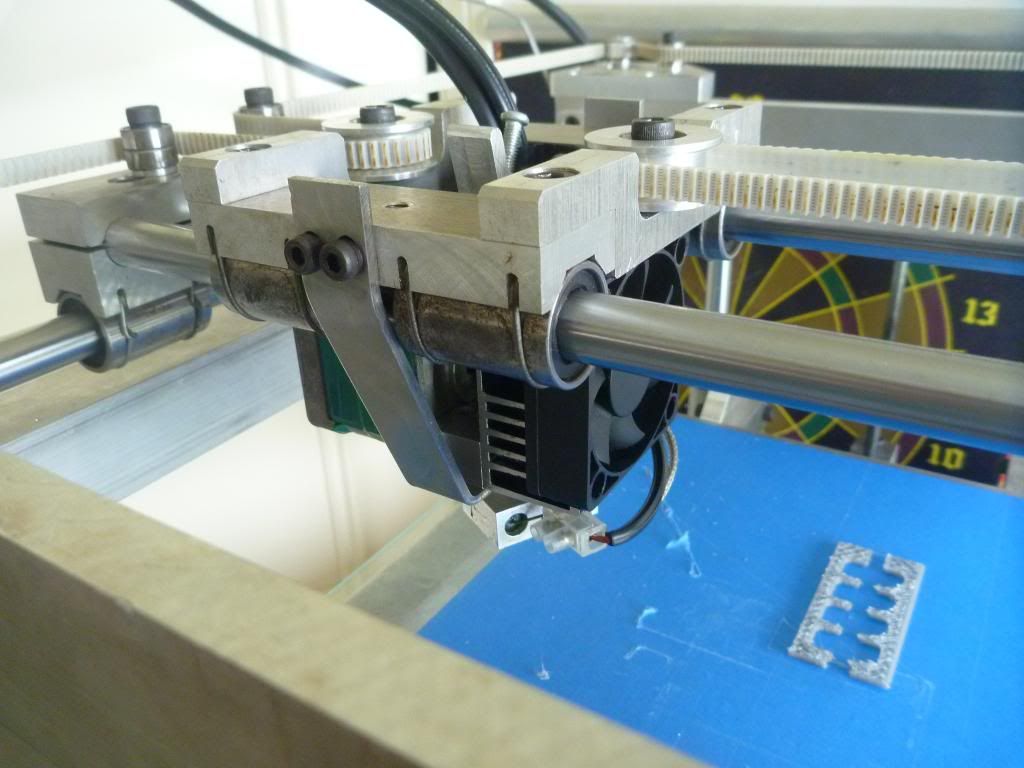

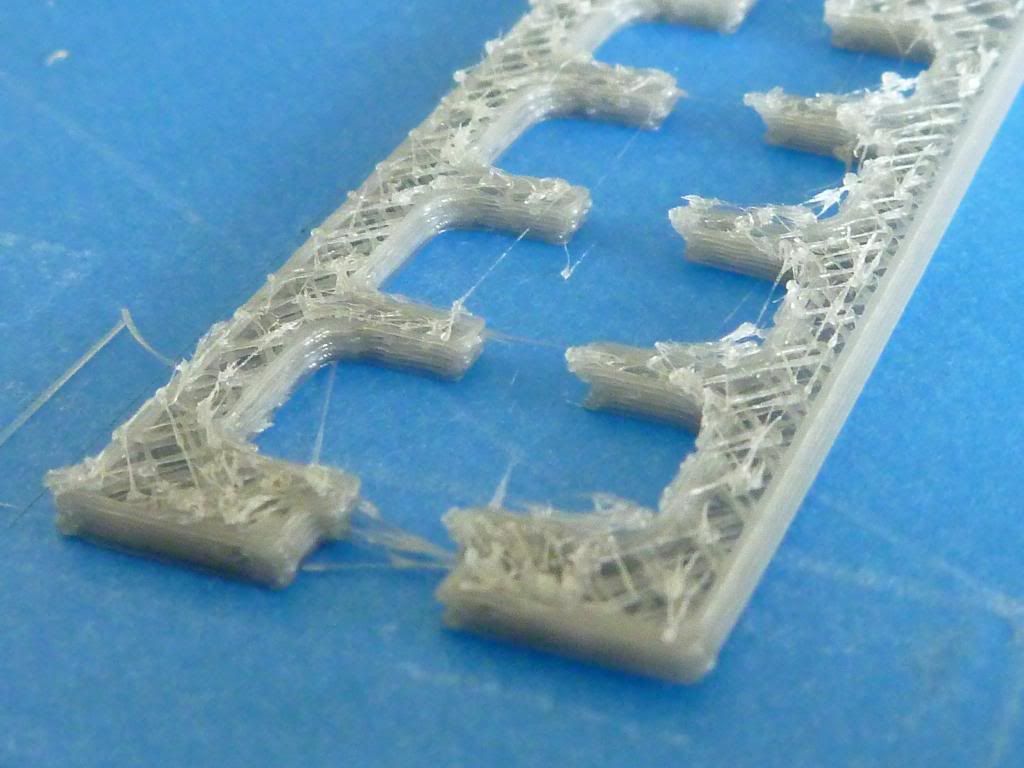

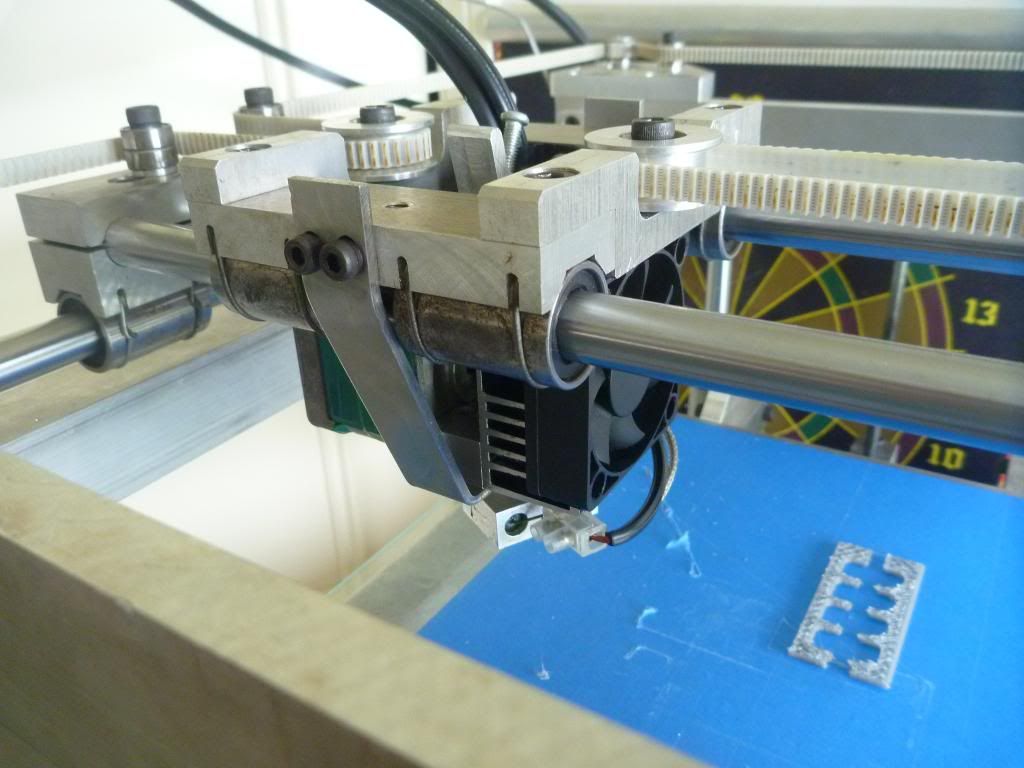

Now comes the problem, Ive been having isues with the extruder blocking due to the filament forming a plug after a while. this results in many partial prints, most of which are around 5mm when they fail

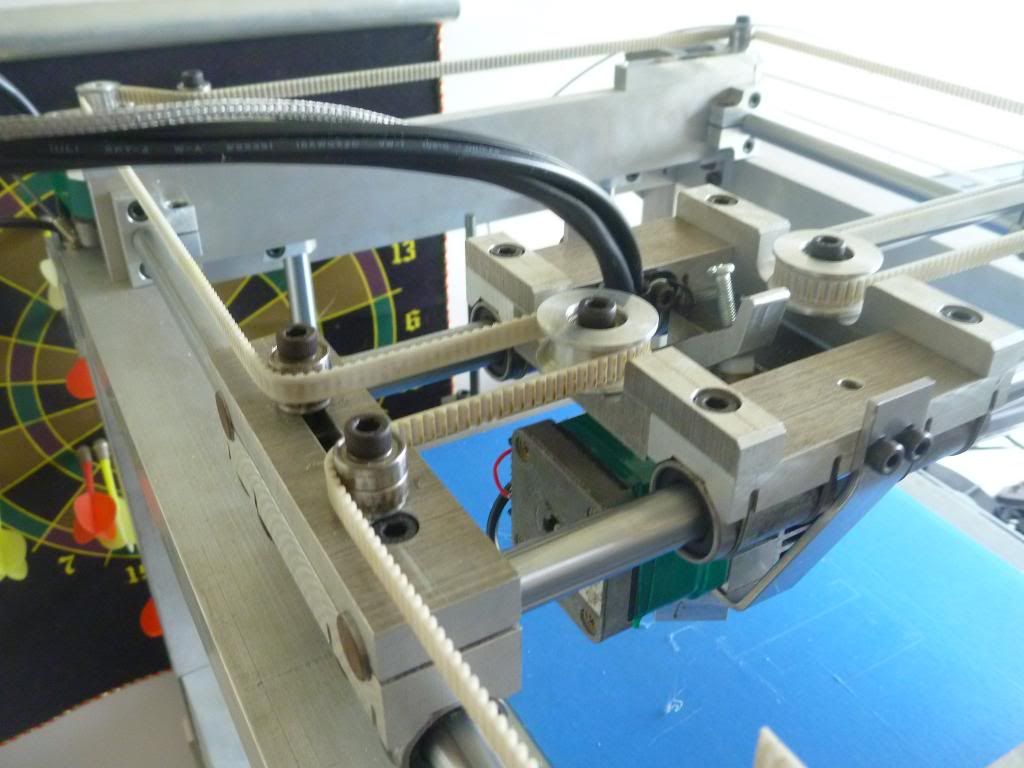

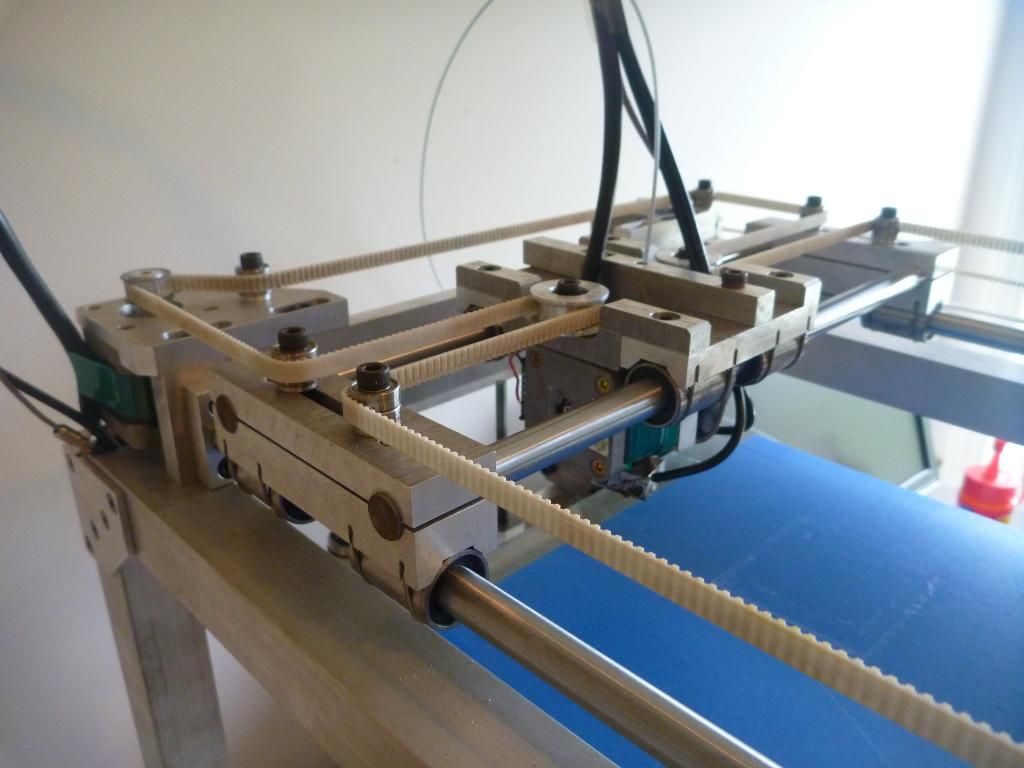

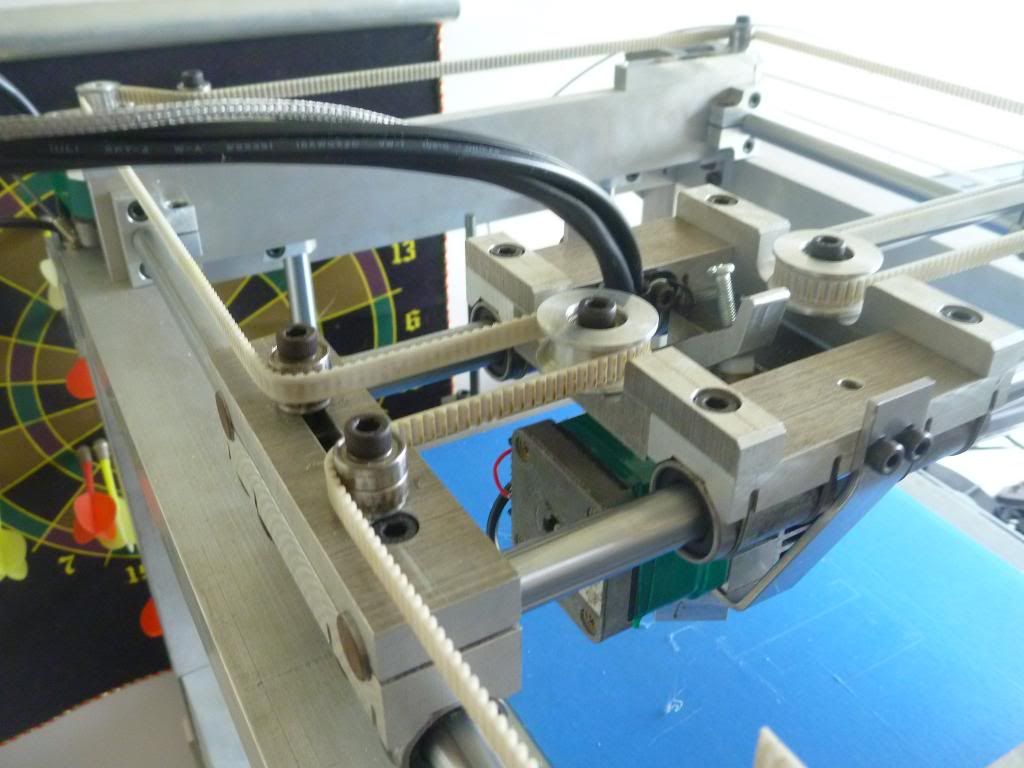

The extruder its self is designed around/ copied from the makerbot mk7 so it should work but no mater what i do i still end up with the same issue. Note a couple of the pics have the previous extruder that i swaped out for the mk7 style one. Im currently running Slic3r and mach3 with linistepper controllers

One thing that im wondering about is that im printing with cheap chinese PLA so this could be the problem but i dont have any high quality plastic to compare to.

Feel free to ask any questions on the settup etc but i would really appreciate and help as ive spent soooo long working on this thing that failure is not an option

BTW sorry if the pics are massive, they look ok on my computer so fingers crossed

Cheers

Jonathan Feist

I know this isnt really the focus of this forum but someone might find it interesting, that and i need as much help as i can get

I started this printer when i was 18 (im 19 almost 20 now) and its been complete for quite some time but ive been messing around with a massive issue for the past 10 months that ive never been able to get past. But first here are the pics

Now comes the problem, Ive been having isues with the extruder blocking due to the filament forming a plug after a while. this results in many partial prints, most of which are around 5mm when they fail

The extruder its self is designed around/ copied from the makerbot mk7 so it should work but no mater what i do i still end up with the same issue. Note a couple of the pics have the previous extruder that i swaped out for the mk7 style one. Im currently running Slic3r and mach3 with linistepper controllers

One thing that im wondering about is that im printing with cheap chinese PLA so this could be the problem but i dont have any high quality plastic to compare to.

Feel free to ask any questions on the settup etc but i would really appreciate and help as ive spent soooo long working on this thing that failure is not an option

BTW sorry if the pics are massive, they look ok on my computer so fingers crossed

Cheers

Jonathan Feist