Well here is the start of my beam engine project. Bore .575", Stroke 1", Cylinder 2" tall, made from 1" Dia Brass stock, Beam 1/8 by 3/4 6" between cl bore and cl of crankpin. shaft 1/4" drill rod, platform 2" by 1/4" brass, flywheel 3-1/4" dia. It will have an exposed shaft kind of reminiscent of a lineshaft. I am also ducting both the intake and exhaust thru the cylinder base not the center of the shaft.

Bill, I hope you don't mind the liberty I took with your design. I do have a question: Is the .013 flat on the shaft depth critical or is it that the flats must be 180 degrees apart?

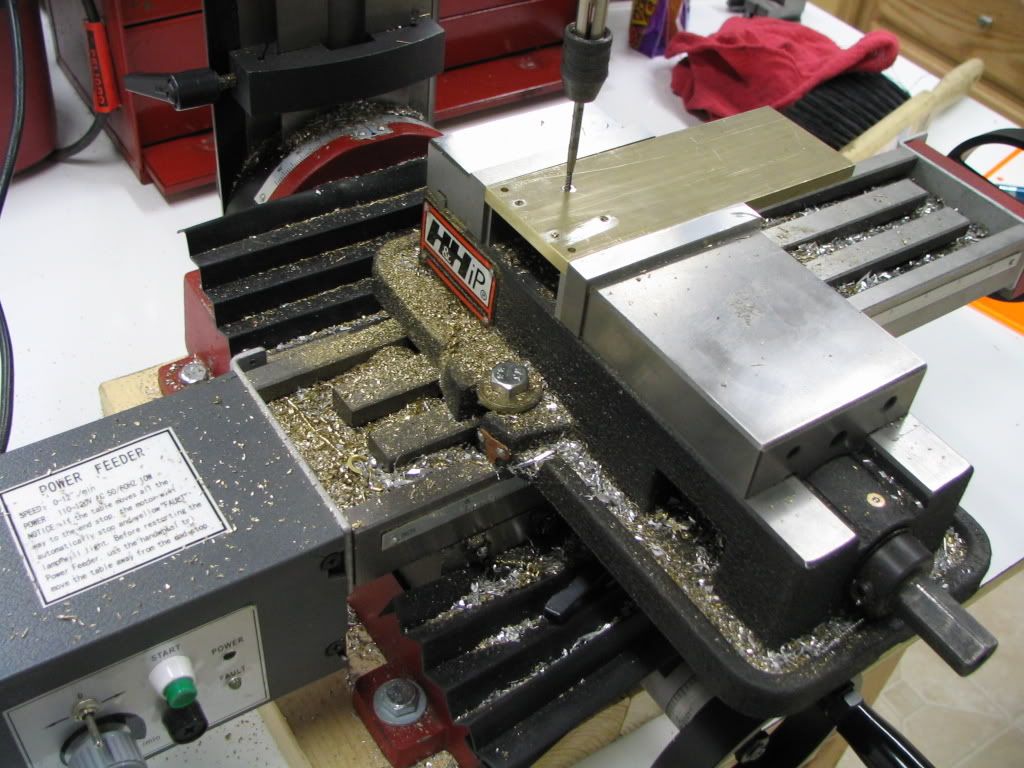

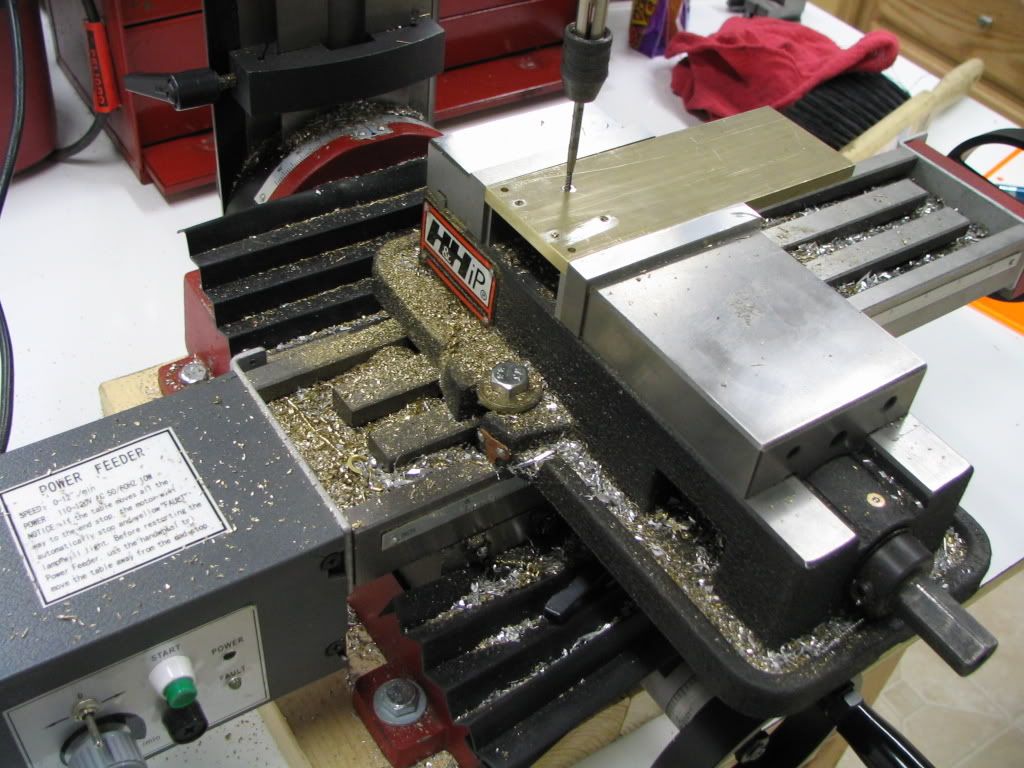

I have also included pictures of Aspen AKA The Swarf Magnet my workshop companion, and a picture showing I do indeed, on occasion Generate some swarf! ;D ;D

Generate some swarf! ;D ;D

Regards, Bret

Bill, I hope you don't mind the liberty I took with your design. I do have a question: Is the .013 flat on the shaft depth critical or is it that the flats must be 180 degrees apart?

I have also included pictures of Aspen AKA The Swarf Magnet my workshop companion, and a picture showing I do indeed, on occasion

Regards, Bret