Hello, I'm new here. I started this engine two years ago. I haven't got much done because of schoolwork, but I'm getting it going again as funds and materials are available. It's a Kinner K5 from Strictly IC plans.

Front Cover, Crankcase, and Gear Case bolted together.

Gear Case, Rear

Oil Tank

Crankcase assembly, and Oil Tank

Crank Webslide side 1

Crank Webslide side 2

Cylinder Head with Rocker Perches

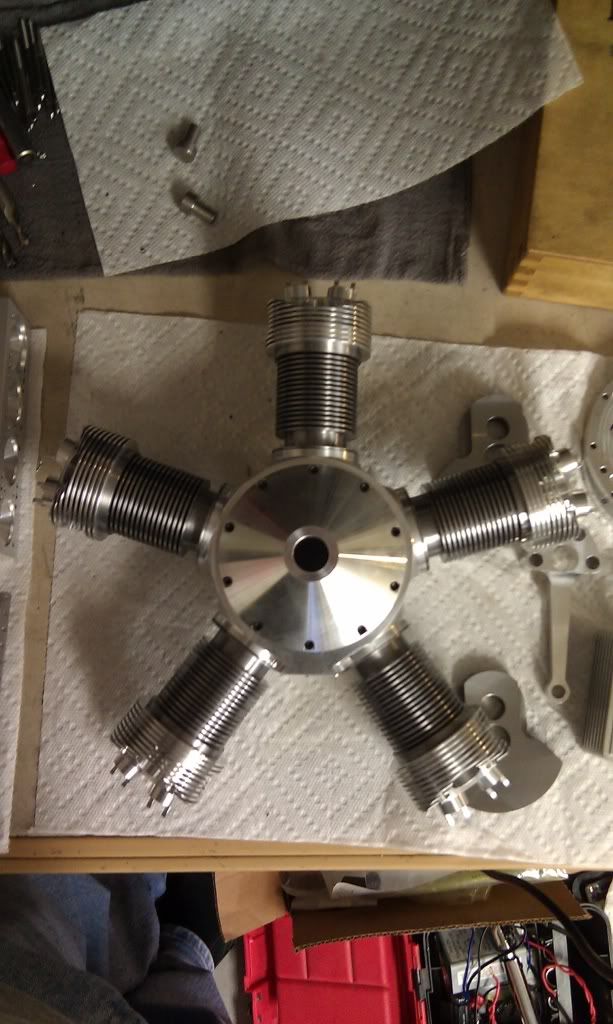

Completed parts to date

Where the magic happens. A bit messy currently.

Hope you like.

Greg

Front Cover, Crankcase, and Gear Case bolted together.

Gear Case, Rear

Oil Tank

Crankcase assembly, and Oil Tank

Crank Webslide side 1

Crank Webslide side 2

Cylinder Head with Rocker Perches

Completed parts to date

Where the magic happens. A bit messy currently.

Hope you like.

Greg