macona

Well-Known Member

- Joined

- Sep 20, 2007

- Messages

- 112

- Reaction score

- 3

Here are some pics of my shop. Most everything was acquired in the last year to year and a half. I have actually very little out of pocket capital in this equipment. A most of the big stuff was a matter of finding some who had what I wanted and finding something for them that they wanted and that did not cost me much!

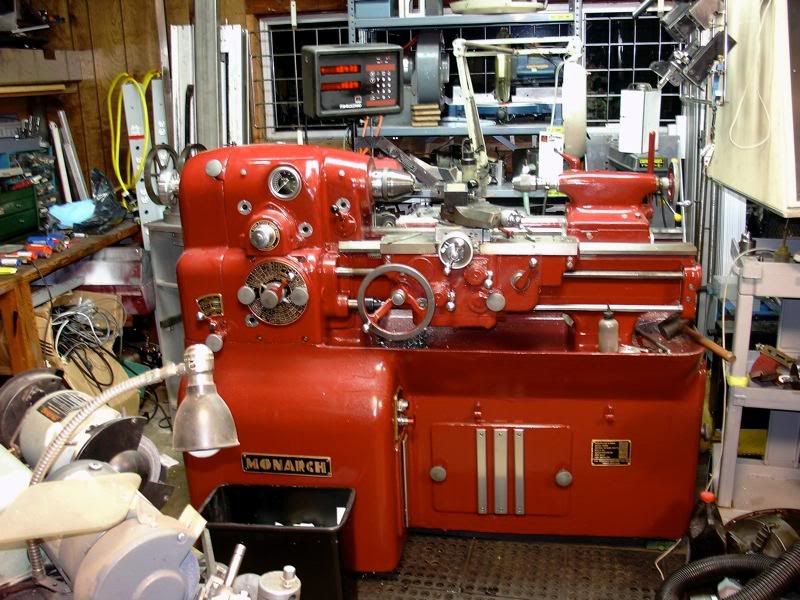

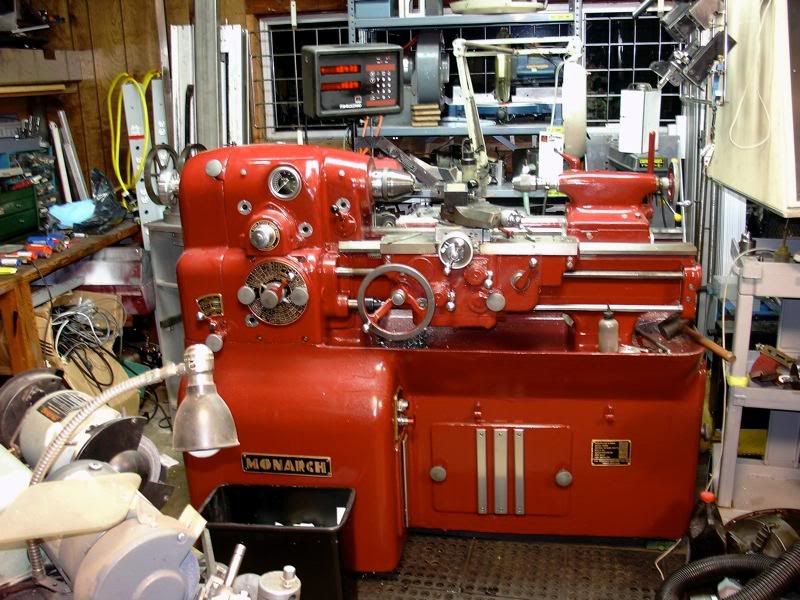

Other things were found through ebay and craigslist. Some required travel like the lathe. I drove with a friend from Portland to LA to get it. 2000 miles round trip. When you want something you have to be prepared to do whats necessary to get it. I WANTED THIS LATHE!

Spent this weekend building a 4th axis for my CNC mill. So things are a bit of a mess.

Pics didnt come out all that great. Will take more when its light out and I need to scrounge up a tripod.

Welding Stuff:

Mill corner:

Lathe Area:

Bench and Gantry Crane:

Tooling and grinders:

Looking in from garage door:

Other things were found through ebay and craigslist. Some required travel like the lathe. I drove with a friend from Portland to LA to get it. 2000 miles round trip. When you want something you have to be prepared to do whats necessary to get it. I WANTED THIS LATHE!

Spent this weekend building a 4th axis for my CNC mill. So things are a bit of a mess.

Pics didnt come out all that great. Will take more when its light out and I need to scrounge up a tripod.

Welding Stuff:

Mill corner:

Lathe Area:

Bench and Gantry Crane:

Tooling and grinders:

Looking in from garage door: