Art K

Well-Known Member

- Joined

- Jul 4, 2012

- Messages

- 218

- Reaction score

- 39

Hi,

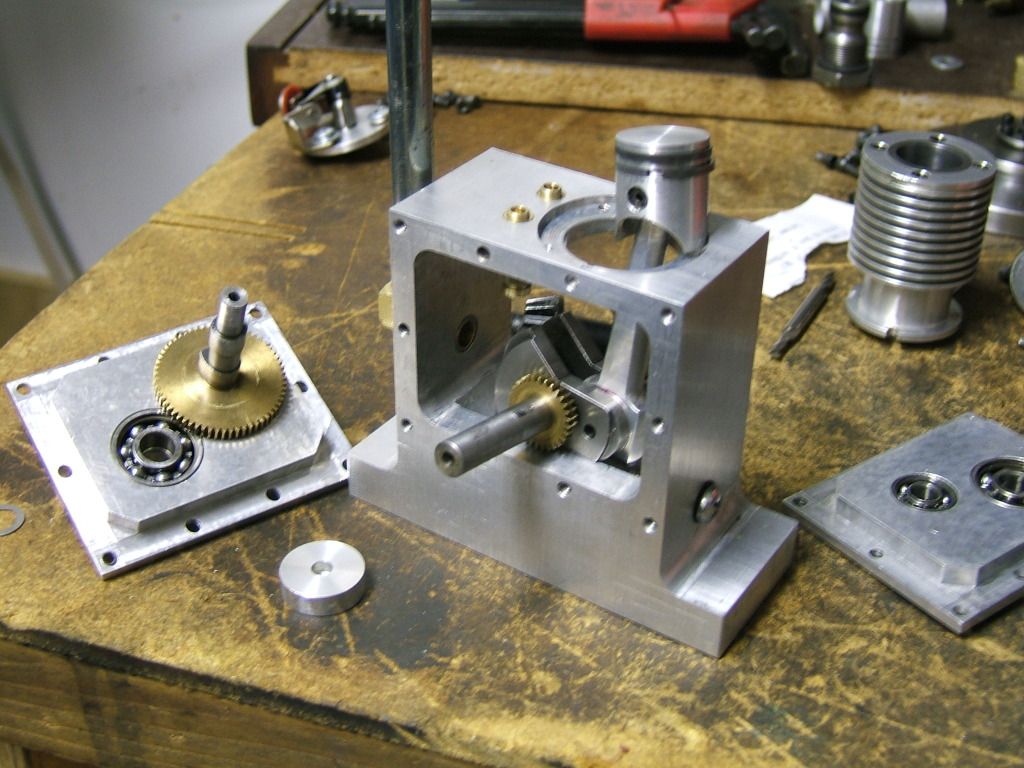

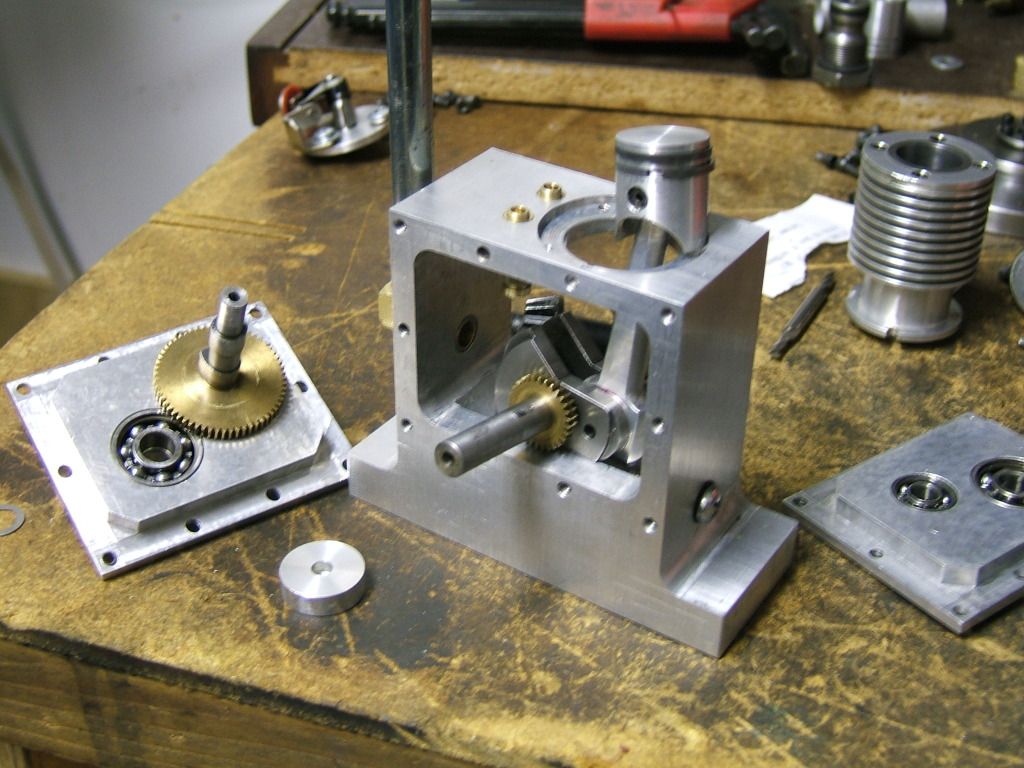

I will try this again. This is my first engine a Hamilton Upshur base vertical single. Bore is 3/4", stroke is 7/8'. all critical dimensions are staight out of the build article in Strictly IC magazine. I modified using stock I had and what I thought would improve it. I originally built but never used (till recently) the single jet carb desighned by Hamilton. I used for some time a Perry RC carb shown in use on this video.[ame="http://www.youtube.com/watch?v=XOaP3us2T3E"] http://www.youtube.com/watch?v=XOaP3us2T3E[/ame]

If I get another Perry carb I would get a smaller one the .197" bore was the closest to the .187 intake dimension but could hardly open the throttle without choking it, made a great governor.

A few other pictures this one is machined prior to final assembly,

These are recent photos with the Upshur designed single jet carb

As well as the Perry worked, it had an incident with to much RPM for to long a period of time causing the carb to droop.

I think I am getting the hang of this,

Art

I will try this again. This is my first engine a Hamilton Upshur base vertical single. Bore is 3/4", stroke is 7/8'. all critical dimensions are staight out of the build article in Strictly IC magazine. I modified using stock I had and what I thought would improve it. I originally built but never used (till recently) the single jet carb desighned by Hamilton. I used for some time a Perry RC carb shown in use on this video.[ame="http://www.youtube.com/watch?v=XOaP3us2T3E"] http://www.youtube.com/watch?v=XOaP3us2T3E[/ame]

If I get another Perry carb I would get a smaller one the .197" bore was the closest to the .187 intake dimension but could hardly open the throttle without choking it, made a great governor.

A few other pictures this one is machined prior to final assembly,

These are recent photos with the Upshur designed single jet carb

As well as the Perry worked, it had an incident with to much RPM for to long a period of time causing the carb to droop.

I think I am getting the hang of this,

Art

Last edited: