David Morrow

Well-Known Member

- Joined

- Sep 8, 2008

- Messages

- 227

- Reaction score

- 60

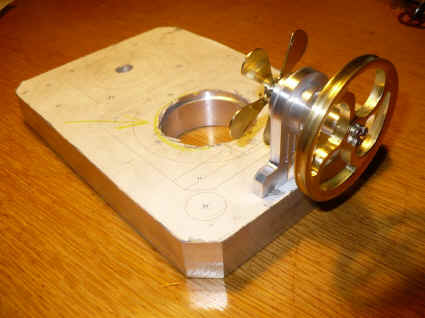

The short version of a long story is that after having built one Moriya ( a variant, really ), I wanted to repeat the experience without building the same thing. So double size it is. I'll post the pic's here and a brief description. For a bit more detail, you can have a look at the build page here :

http://www.ldrider.ca/cnc/moriya-double/moriya-double-1.htm

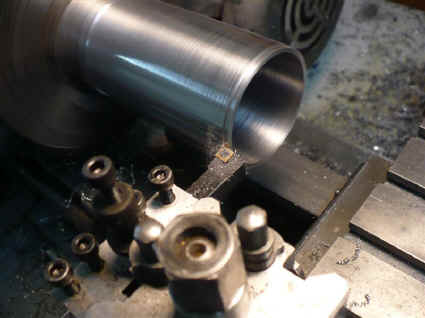

The material for this thing, at least the material for the base and the displacer cylinder are awfully big for my little Sherline CNC mill and Myford S7 lathe.

I cut the 1" thick slab of aluminum down to size first on the band saw.

Next, I printed and glued the cad drawing to the work piece. For more complex jobs this really helps ensure everything gets done and in the right order.

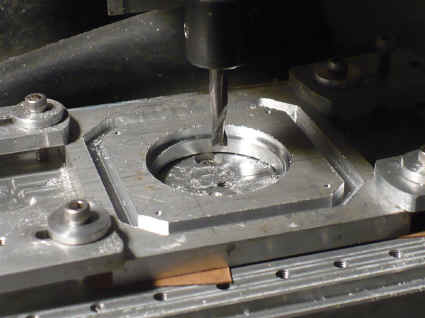

The bulk of the displacer hole gets cut out with a hole saw. This takes all of 2-3 minutes on the drill press and means much easy job for the light mill.

Being so thick, I don't like to commit to milling down 1 inch as part of a single operation. So, I break it up into smaller jobs of about .250" - .350" at a time.

I got a bit ahead of myself in the beginning. A sneak preview... but it's a secret so do tell and don't ask.

http://www.ldrider.ca/cnc/moriya-double/moriya-double-1.htm

The material for this thing, at least the material for the base and the displacer cylinder are awfully big for my little Sherline CNC mill and Myford S7 lathe.

I cut the 1" thick slab of aluminum down to size first on the band saw.

Next, I printed and glued the cad drawing to the work piece. For more complex jobs this really helps ensure everything gets done and in the right order.

The bulk of the displacer hole gets cut out with a hole saw. This takes all of 2-3 minutes on the drill press and means much easy job for the light mill.

Being so thick, I don't like to commit to milling down 1 inch as part of a single operation. So, I break it up into smaller jobs of about .250" - .350" at a time.

I got a bit ahead of myself in the beginning. A sneak preview... but it's a secret so do tell and don't ask.