My last design contract is finished and I have a little money to spend. I want to know a "top of the line" carbide inserts and holder to fit my quick change toolpost on my 12' x 28" lathe. I have tried the HSS inserts and holder from Arthur Warner, and although they work very well, they dull very quickly. They can be sharpened about 15 times before they are "done". I have tried another set of carbides and holders from Shars, but they too didn't seem to stand up very well. 95% of my lathe work is on mild steel or cold rolled steel less than 1 1/2" diameter, the remaining 5% is aluminum and very little brass. I have a bunch of brazed carbide tools that I was given, and I use them a fair amount. My general turning speed is 500 to 600 rpm. Probable about 1/4 of my work involves interrupted cuts. I see many guys using diamond shaped carbide inserts, and they have only two cutting points that can be used, but because of their shape they can get into tight places. I see other guys using triangular shaped inserts, which gives 3 available cutting edges, which seems more economical because you get three cutting "points" rather than the two cutting points you get from a diamond shaped carbide. I use my lathe a lot. Can somebody make a recommendation for tools that can be bought in North America. I am a bit lost in this quest, and would appreciate any advice from people who have used this tooling.----Brian rupnow

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Money to spend on inserts and holder for lathe

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

dnalot

Project of the Month Winner !!!

I have been using the "economy insert holders" from McMaster Carr and their line of inserts. I have been happy with them but then I have no experience with anything else.

Mark T

Mark T

Take a look at Banggood stuff. Just used a threading insert tool yesterday, worked great as usual. Their small cutoff tool and insert is particularly good. Pennies on the dollar compared to others.

xpylonracer

Well-Known Member

Brian

Some info about insert shape and designation at this link to help you decide:

http://www.jbcuttingtools.com/epage...=/Shops/es461493/Categories/"Turning inserts"

I tend to keep with the polished type inserts for most work as like you I don't drive my lathe hard, fairly low

speeds and light DOC.

Details of the insert numbers and description of inserts can be found here:

http://www.helmancnc.com/general-turning-insert-nomenclature-for-cnc-dummies/

Some info about insert shape and designation at this link to help you decide:

http://www.jbcuttingtools.com/epage...=/Shops/es461493/Categories/"Turning inserts"

I tend to keep with the polished type inserts for most work as like you I don't drive my lathe hard, fairly low

speeds and light DOC.

Details of the insert numbers and description of inserts can be found here:

http://www.helmancnc.com/general-turning-insert-nomenclature-for-cnc-dummies/

Last edited:

- Joined

- Oct 1, 2010

- Messages

- 1,341

- Reaction score

- 393

Brian,

I suggest you check out KBC tools.

www.kbctools.com

In my opinion they are a good source for cutting tools of all types. Their descriptions of the carbide holders they sell and inserts are very good and all dimensions are clearly noted.

they have branches in Canada as well in the. U.S. I have talked to people there who are happy to help, even with small purchases. (Usual disclaimer, only a customer and no ties to them.)

In my own experience, with 5/16 and 3/8 shank tooling on my lathe, I have experimented with different insert systems and geometries and find they can work well under the right conditions. I don't know about the interrupted cuts, as I usually use HSS for that. (My understanding is that carbides are brittle and fracture more easily, thus I use HSS for interrupted cuts.)

I have purchased several different types of inserts and have decided that If I use them, I need more than one type. I started with the triangular inserts with chipbreakers (T**), I got some of the narrow parallelogram type (V***) for better reach (I bought the inserts and made holders for them.) I am presently intermittantly using CCMT inserts in both a lathe tool and a boring bar (reduces the types I need to keep on hand.) With CCMT, my attempt on the lathe was to find a setup that would result in moving from straight L-R cutting to facing without having to re-index the cutting angle. This goes along with having my QCTP set for cutting as above, then having a toolholder swap with a chamfering tool without a re-index as well.

What I have not done with carbide is parting and threading, although I am considering a carbide-insert system for cutting small threads.

Returning to the Carbide vs. HSS discussion, I have confirmed the advice I have seen that Carbides need deeper cuts and steady pressure to work well instead of the smaller, shallower cuts that HSS is good with. (In other words, carbide probably not good with the "spring pass"). Your larger lathe would probably work better with carbides than my small lathe, if you were taking off large amounts.

--ShopShoe

I suggest you check out KBC tools.

www.kbctools.com

In my opinion they are a good source for cutting tools of all types. Their descriptions of the carbide holders they sell and inserts are very good and all dimensions are clearly noted.

they have branches in Canada as well in the. U.S. I have talked to people there who are happy to help, even with small purchases. (Usual disclaimer, only a customer and no ties to them.)

In my own experience, with 5/16 and 3/8 shank tooling on my lathe, I have experimented with different insert systems and geometries and find they can work well under the right conditions. I don't know about the interrupted cuts, as I usually use HSS for that. (My understanding is that carbides are brittle and fracture more easily, thus I use HSS for interrupted cuts.)

I have purchased several different types of inserts and have decided that If I use them, I need more than one type. I started with the triangular inserts with chipbreakers (T**), I got some of the narrow parallelogram type (V***) for better reach (I bought the inserts and made holders for them.) I am presently intermittantly using CCMT inserts in both a lathe tool and a boring bar (reduces the types I need to keep on hand.) With CCMT, my attempt on the lathe was to find a setup that would result in moving from straight L-R cutting to facing without having to re-index the cutting angle. This goes along with having my QCTP set for cutting as above, then having a toolholder swap with a chamfering tool without a re-index as well.

What I have not done with carbide is parting and threading, although I am considering a carbide-insert system for cutting small threads.

Returning to the Carbide vs. HSS discussion, I have confirmed the advice I have seen that Carbides need deeper cuts and steady pressure to work well instead of the smaller, shallower cuts that HSS is good with. (In other words, carbide probably not good with the "spring pass"). Your larger lathe would probably work better with carbides than my small lathe, if you were taking off large amounts.

--ShopShoe

Hi Brian,

KBC tool in Canada has a fair amount of inserts. In the US they are a reputable supplier, so odds are they are in Canada as well.

If you happen to have a means of taking delivery at a US address, latheinserts.com is a good supplier. Only better to high grade products, not a "quality import" sort of place. Everything ever purchased from them has been excellent. Sadly they don't ship to Canada.

Carbide Depot is also a good supplier, but they charge UPS $50 to ship to Canada before added charges. You folks in the great white north really get hosed by shipping from the US from what I've heard.

A good carbide nomenclature chart is here:

http://www.carbidedepot.com/formulas-insert-d.htm

As you've already found, ignore the amazon 10 for $25 "first top rate to be cutting your metal much we like" garbage, just wasted money. Some reputable vendors do have quite good house branded inserts, I've gotten Kyocera, Iscar and other top quality inserts in OEM packaging with the house brand sticker partially covering the makers own labels.

If your Warner tool holders take the diamond inserts (CCMTxxxx) treat yourself to some good inserts and try them out. Good inserts last MUCH longer than cheap ones, the cost of changing tool holders to get one more tip may not be worth it.

If you already have triangular insert toolholders you're half way there. You need positive rake inserts (TCMT, TPxxxxxx) for steel to work well. The insert size is measured in 1/8's of an inch diameter of an inscribed circle, so a TCMT321 will have it's straight edges tangent to a 3/8 inch circle centered around the mounting screw. The second digit is thickness in 1/16s of an inch, almost always a "2" in these size inserts. The last digit is the tip radius in 0.016 inch increments. A TPG321 or a TCMT321 will have a 0.016 inch tip radius. Just as in HSS tools you grind, the larger the radius the longer the tip tends to last and the smoother the finish but the less tight the corners and the more spindle power needed for a significant depth of cut.

There is also an ANSI/ISO nomenclature that has 4 digits and a decimal. Same basic deal - a TCMT32.51 insert is the same as a 321 EXCEPT the thickness is 0.156 inch. Not a big deal, but it does change the cutting edge height when mounted in the lathe. Try not to have both thicknesses in stock, it sucks to replace a worn insert and not notice the new insert is either high or low by 30 thou. Done it, took a moment or two to realize what was going on.

The AR Warner tooling is nice, when most of my work was in brass I loved the fact that their inserts could be polished and had zero rake. In steel the use of small positive rake inserts such as CCMT221 or CCMT21.51 diamond and TPG221 triangular inserts improved finish quality noticeably over the zero rake inserts.

If you have lower cost indexed tool holders, look carefully at the insert pocket and see that it is truly flat and the corner(s) are relieved so the insert sits solidly. Lap/hone/use method of choice to make the pocket floor flat if needed. A rocking insert is a chattering broken insert. Really high end holders often come with a carbide anvil the insert sits on, but most of us don't spend that sort of money on our tool holders.

I'm guessing you already know that carbide hates to scrape and hates thermal shock. Cut hard, cut deep, cut to size, and don't spritz on a little cold coolant or thin oil now and then. Cut wet or cut dry, once it's at a blue chip heat hitting the cutter with cold liquid will likely either crack it or fracture the edge at a minimum. A 0.002 inch depth of cut and a tentative feed rate will give poor finish and high wear on the insert. It's OK once in a while if you must, but the real deal is to have most of the heat of cutting leaving with the chips, not hanging around in dust.

Hope this is of some help,

Stan

KBC tool in Canada has a fair amount of inserts. In the US they are a reputable supplier, so odds are they are in Canada as well.

If you happen to have a means of taking delivery at a US address, latheinserts.com is a good supplier. Only better to high grade products, not a "quality import" sort of place. Everything ever purchased from them has been excellent. Sadly they don't ship to Canada.

Carbide Depot is also a good supplier, but they charge UPS $50 to ship to Canada before added charges. You folks in the great white north really get hosed by shipping from the US from what I've heard.

A good carbide nomenclature chart is here:

http://www.carbidedepot.com/formulas-insert-d.htm

As you've already found, ignore the amazon 10 for $25 "first top rate to be cutting your metal much we like" garbage, just wasted money. Some reputable vendors do have quite good house branded inserts, I've gotten Kyocera, Iscar and other top quality inserts in OEM packaging with the house brand sticker partially covering the makers own labels.

If your Warner tool holders take the diamond inserts (CCMTxxxx) treat yourself to some good inserts and try them out. Good inserts last MUCH longer than cheap ones, the cost of changing tool holders to get one more tip may not be worth it.

If you already have triangular insert toolholders you're half way there. You need positive rake inserts (TCMT, TPxxxxxx) for steel to work well. The insert size is measured in 1/8's of an inch diameter of an inscribed circle, so a TCMT321 will have it's straight edges tangent to a 3/8 inch circle centered around the mounting screw. The second digit is thickness in 1/16s of an inch, almost always a "2" in these size inserts. The last digit is the tip radius in 0.016 inch increments. A TPG321 or a TCMT321 will have a 0.016 inch tip radius. Just as in HSS tools you grind, the larger the radius the longer the tip tends to last and the smoother the finish but the less tight the corners and the more spindle power needed for a significant depth of cut.

There is also an ANSI/ISO nomenclature that has 4 digits and a decimal. Same basic deal - a TCMT32.51 insert is the same as a 321 EXCEPT the thickness is 0.156 inch. Not a big deal, but it does change the cutting edge height when mounted in the lathe. Try not to have both thicknesses in stock, it sucks to replace a worn insert and not notice the new insert is either high or low by 30 thou. Done it, took a moment or two to realize what was going on.

The AR Warner tooling is nice, when most of my work was in brass I loved the fact that their inserts could be polished and had zero rake. In steel the use of small positive rake inserts such as CCMT221 or CCMT21.51 diamond and TPG221 triangular inserts improved finish quality noticeably over the zero rake inserts.

If you have lower cost indexed tool holders, look carefully at the insert pocket and see that it is truly flat and the corner(s) are relieved so the insert sits solidly. Lap/hone/use method of choice to make the pocket floor flat if needed. A rocking insert is a chattering broken insert. Really high end holders often come with a carbide anvil the insert sits on, but most of us don't spend that sort of money on our tool holders.

I'm guessing you already know that carbide hates to scrape and hates thermal shock. Cut hard, cut deep, cut to size, and don't spritz on a little cold coolant or thin oil now and then. Cut wet or cut dry, once it's at a blue chip heat hitting the cutter with cold liquid will likely either crack it or fracture the edge at a minimum. A 0.002 inch depth of cut and a tentative feed rate will give poor finish and high wear on the insert. It's OK once in a while if you must, but the real deal is to have most of the heat of cutting leaving with the chips, not hanging around in dust.

Hope this is of some help,

Stan

grahamgollar

Well-Known Member

I guess you won't wish to buy via the UK but it's worth looking at the Cutwell site on the old interweb: Lathe Tools/ISO Turning Inserts, Tool Holders & Boring Bars | Cutwel - Lathe Tool Specialist Cutwel Ltd . Their literature is very informative regarding tool nomenclature, sizes and applications etc and helps you (hopefully) to chose the correct insert from the bewildering plethora of alternatives available nowadays. They market mainly Korloy and YG inserts (you'll have to imagine the TM marker here!) which are probably available in your distant climes.

Graham

Graham

grahamgollar

Well-Known Member

That web address didn't print true, here's the correct one:

https://www.cutwel.co.uk/lathe-tools/iso-turning-inserts-tool-holders-boring-bars

https://www.cutwel.co.uk/lathe-tools/iso-turning-inserts-tool-holders-boring-bars

Brian, Have you looked into Sandvik holders and inserts?

These are what I use on my small lathe Delta, and my large lathe Colchester 17x80.

I have bought holders and inserts off the Bay, They are very durable, the inserts have chip breaking geometry designed into the insert. There are many different insert designs in the different insert shapes and nose radius's. Cheap and quality doesn't go hand in hand. There are also Seco, good products.

These are what I use on my small lathe Delta, and my large lathe Colchester 17x80.

I have bought holders and inserts off the Bay, They are very durable, the inserts have chip breaking geometry designed into the insert. There are many different insert designs in the different insert shapes and nose radius's. Cheap and quality doesn't go hand in hand. There are also Seco, good products.

I have one of the 5 piece 3/8's turning set from AR Warner which I love . Still on my original inserts & have the unused spare insert that comes with the set after @ 5-6 years . When I asked them about using carbide on their holders they told me to get TPMT carbide inserts . I haven't made the jump tp carbide yet cause I haven't had time to frame in a machine room in our new place & my South Bend maxes out @ 1200-1500 rpm . So going on what they told me you can start without not buying any tool holders since you already have some . I would like to get one with inserts on both ends , so I can turn & the swat the tool holder & chamfer the part with the same tool holder . Keep us posted on what you end up with .

animal

animal

Brian if you want to get the most use out of inserts then you can buy holders that use the two "spare" corners of the common CCMT and CCGT inserts as well as boring bar holders so one shape insert will do most jobs and just throw in a holder for DCMT / DCGT for fine work like valve stems

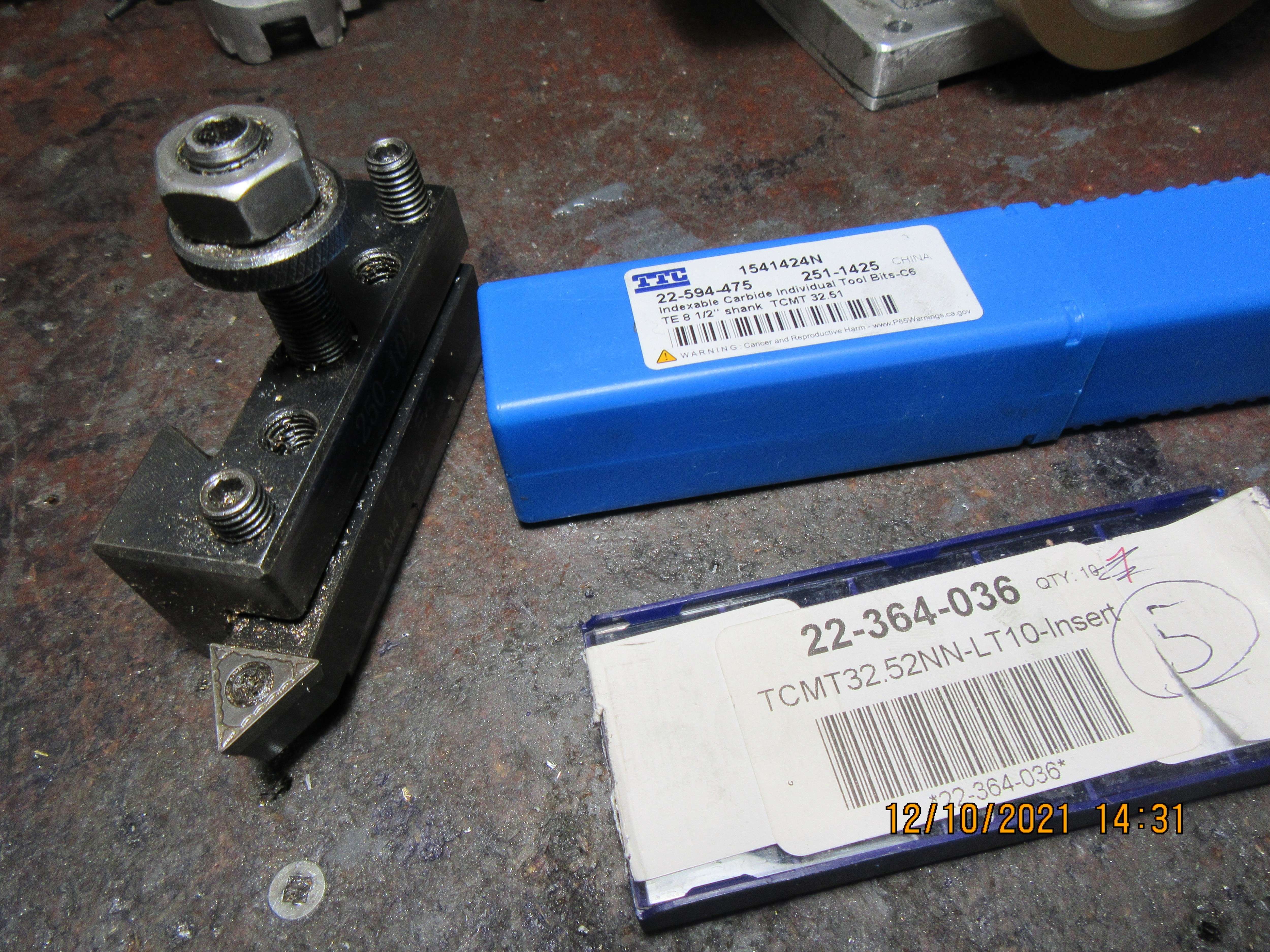

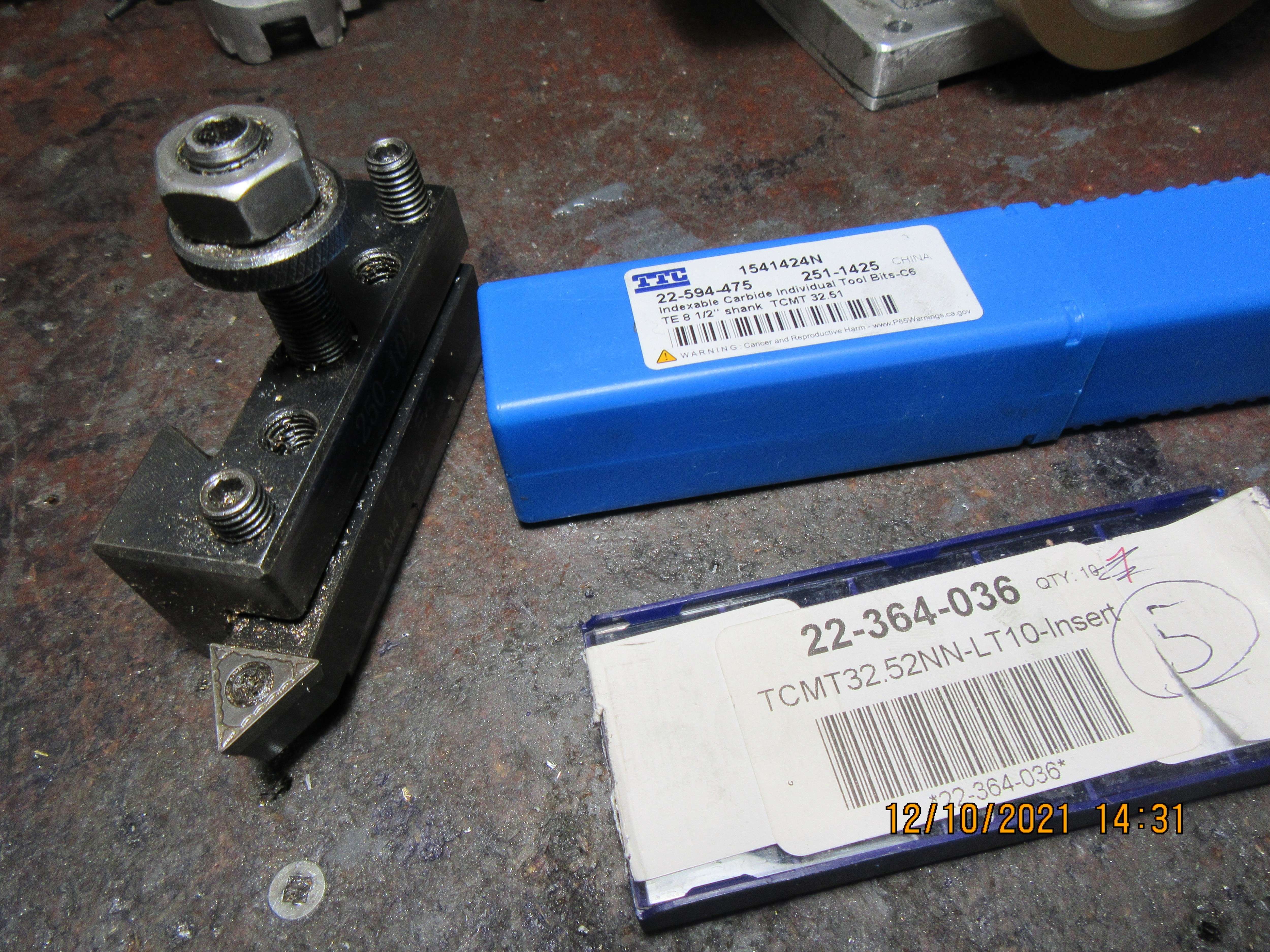

Okay---To bring this thread up to date---this is what I bought. It seems to work very well for what I do and the carbide hasn't chipped nor broken on interrupted cuts. I can take 0.020" depth of cut in cold rolled steel, and it doesn't seem to mind a bit. I bought the toolholder with a 1/2" square shank and didn't realize until it got here that my quick change toolpost would only work with 3/8" square tooling. In order to get the carbide down to the lathes centerline I had to remove 0.125" from the bottom of one tool holder, but that's okay, that toolholder is dedicated to this particular tool. It wasn't cheap, I think I paid close to $170 Canadian for the tool and five inserts. Each insert has three points, so I hope to get a good long life from this.

I have not read this thread until now, and I am a little surprised nobody has commented on this in Brian's OP: "My general turning speed is 500 to 600 rpm."

Brian, if you, the lathe, the tool, and the workpiece seem to like that, I am not going to argue. But I would like a bit more detail. Do you not select a cutting speed at least with an eye to size and material?

Brian, if you, the lathe, the tool, and the workpiece seem to like that, I am not going to argue. But I would like a bit more detail. Do you not select a cutting speed at least with an eye to size and material?

trlvn

Well-Known Member

Where did you purchase these?$170 Canadian for the tool and five inserts

What convinced you to go with the triangular shape as opposed to, say, diamond shape?

Craig

I bought them from Travers in Canada. I went with the 3 cornered insert because you get one more cutting edge than with a diamond shaped insert.

I Used inserts for about 20 years and switch back to grinding high speed steel. Still have a drawer full inserts.

I found I could get better job out of a grinding the tool for job.

Dave

I found I could get better job out of a grinding the tool for job.

Dave

My last design contract is finished and I have a little money to spend. I want to know a "top of the line" carbide inserts and holder to fit my quick change toolpost on my 12' x 28" lathe. I have tried the HSS inserts and holder from Arthur Warner, and although they work very well, they dull very quickly. They can be sharpened about 15 times before they are "done". I have tried another set of carbides and holders from Shars, but they too didn't seem to stand up very well. 95% of my lathe work is on mild steel or cold rolled steel less than 1 1/2" diameter, the remaining 5% is aluminum and very little brass. I have a bunch of brazed carbide tools that I was given, and I use them a fair amount. My general turning speed is 500 to 600 rpm. Probable about 1/4 of my work involves interrupted cuts. I see many guys using diamond shaped carbide inserts, and they have only two cutting points that can be used, but because of their shape they can get into tight places. I see other guys using triangular shaped inserts, which gives 3 available cutting edges, which seems more economical because you get three cutting "points" rather than the two cutting points you get from a diamond shaped carbide. I use my lathe a lot. Can somebody make a recommendation for tools that can be bought in North America. I am a bit lost in this quest, and would appreciate any advice from people who have used this tooling.----Brian rupnow

Although I have a set of insert tools for my Boxford lathe I really don't rate carbide tooling for model work , except perhaps for roughing out. I use good quality HSS , mine was all produced in the UK many years ago.

It can be sharpened to a razor edge with a diamond hone and can remove a whisker half a thou thick when used in my Pultra lathe.

I made this quick change tool post with a dozen or so tool holders fitted with a range of HSS form tools etc

Dan.

It can be sharpened to a razor edge with a diamond hone and can remove a whisker half a thou thick when used in my Pultra lathe.

I made this quick change tool post with a dozen or so tool holders fitted with a range of HSS form tools etc

Dan.

Last edited:

Having used my Grandfather's carbon steel tools, tools made from broken files, HSS and carbide tools, I can only say that HSS is the most versatile tool material, but inserts honed on a diamond wheel can be sharpened to the shape you want - and a near razor-edge if you are careful (fine for brass/aluminium/nylon at speed). But they are not without risk of chipping the edge... (a bit like knapping flint!). Funny... I use all sorts of speeds below 1200rpm - "as that was what I grew up with on pre-1950s lathes). But I don't remove large amounts of material to need modern speeds and feeds.... (Only make tiddly little things - a 0.020" cut and hand feed that "sounds right" suits me. And my little lathes and motors won't do the work, and are not stiff enough to remain accurate, with larger cuts and feeds.).

Another thing: too fast on CI simply grinds the tool, instead of cutting the CI.

But I wish I had a back-gear to develop more torque at low speed... Electronic Variable Speed is convenient, but lacking in low speed torque.

"Each to his own" is my conclusion, until you want "industrial" levels of metal removal.

K2

Another thing: too fast on CI simply grinds the tool, instead of cutting the CI.

But I wish I had a back-gear to develop more torque at low speed... Electronic Variable Speed is convenient, but lacking in low speed torque.

"Each to his own" is my conclusion, until you want "industrial" levels of metal removal.

K2

But I wish I had a back-gear to develop more torque at low speed... Electronic Variable Speed is convenient, but lacking in low speed torque.

"Each to his own" is my conclusion, until you want "industrial" levels of metal removal.

This is where carbide helps us as you can run 3-4 times faster than HSS so where you may have used a slow backgear on something like a flywheel with HSS you can run a faster spindle speed which helps put the motor into is's power band with carbide. My lathe is essentially the same as Brian's and I use 2-300rpm on 9" cast iron flywheels and tool life is fine.

I would be taking off about a 20thou cut at that dia and a fine feed but the lathe is capable of a much deeper cut as the diameter comes down.

Last edited:

Thanks Jason, what cutting speeds do you propose for HSs and Carbide inserts? - for both Mild steel, and CI, and maybe brass as well? Ft/min. or m/s, or whatever you have and I'll calculate running speeds per diameter for these and make a table.

I currently use a drill-speed table per material - and tweak it a bit by "feel and ear" as a quick guide, as it saves me calculating everything when I want to be making swarf.

The odd thing is that I have never come across a milling speed per material table? - Again, "feel and ear" gives me good results, usually by adjusting hand feed rate. But that's what I did as an "apprentice", based on some rudimentary speeds and feeds that the experienced fitters taught me (that I have forgotten. Too many years in industry, not involved with machining details.).

Thanks,

K2

I currently use a drill-speed table per material - and tweak it a bit by "feel and ear" as a quick guide, as it saves me calculating everything when I want to be making swarf.

The odd thing is that I have never come across a milling speed per material table? - Again, "feel and ear" gives me good results, usually by adjusting hand feed rate. But that's what I did as an "apprentice", based on some rudimentary speeds and feeds that the experienced fitters taught me (that I have forgotten. Too many years in industry, not involved with machining details.).

Thanks,

K2

Similar threads

- Replies

- 1

- Views

- 540

- Replies

- 0

- Views

- 384

- Replies

- 2

- Views

- 731

- Replies

- 0

- Views

- 418

- Replies

- 0

- Views

- 379