Seagar---I assume NSW is New South Wales, right? I kinda wish we were next door neighbours too.----Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Model Sawmill Dreaming---

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

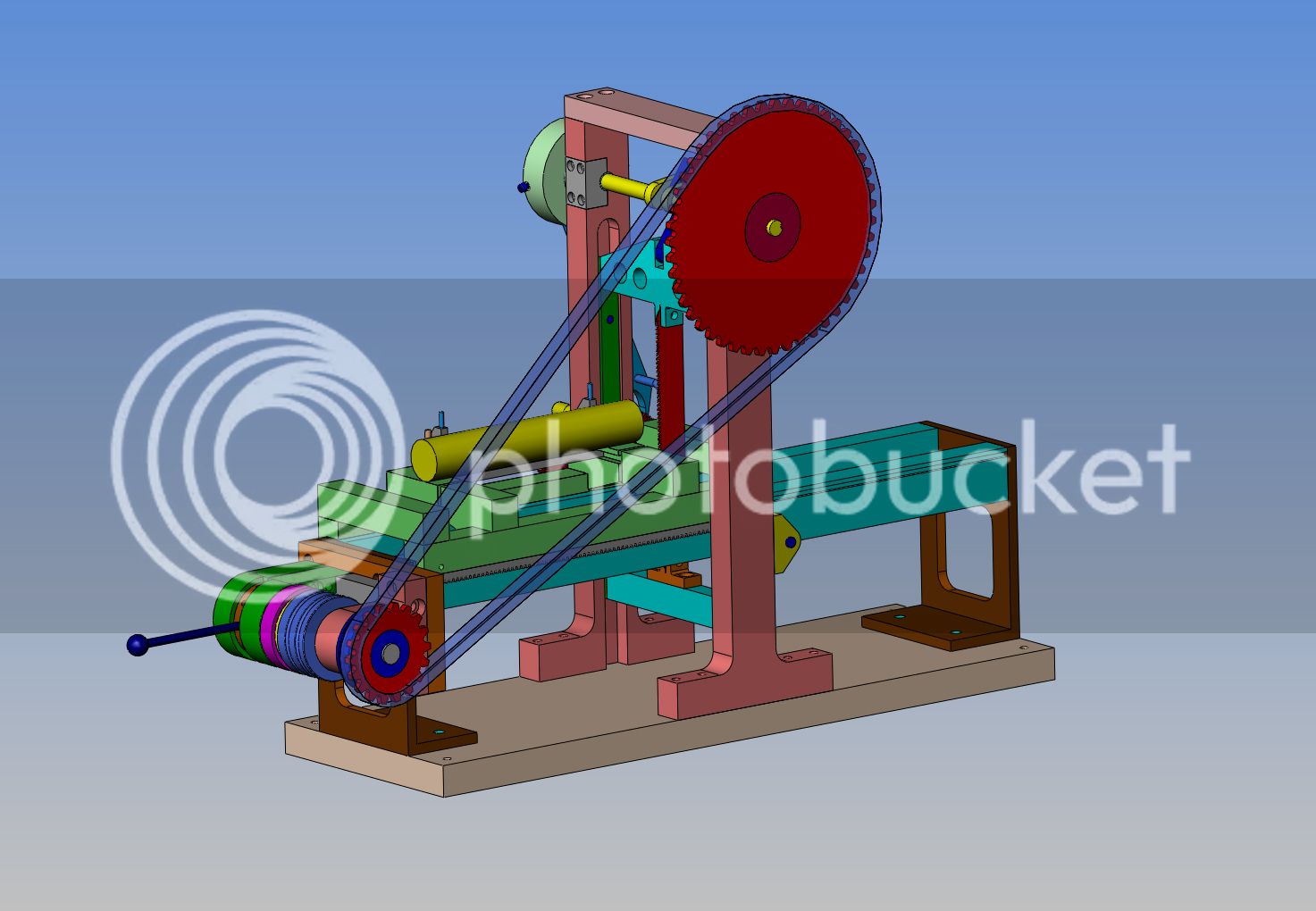

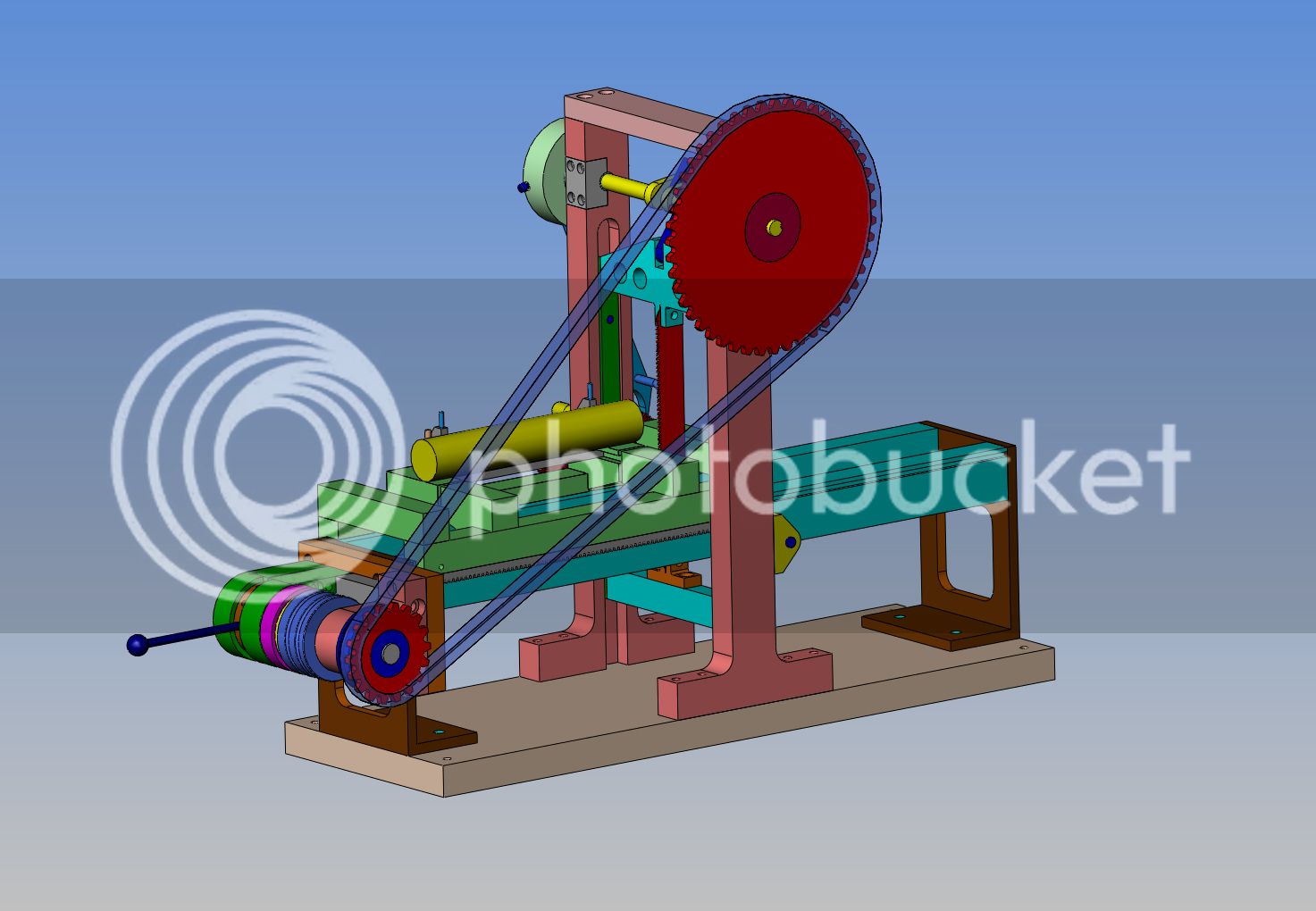

So--a bit of design time in early this morning before goodwife gets up, and I think I've found a good position to mount the clutch and the sprockets and chain.

Yowzah!!! That went pretty easy, all things considered. I wanted to get the clutch mounted to the sawmill frame. That way I can move it as a unit and run it with whatever engine I want. I haven't changed the pawl gear yet, but I'll do it this weekend.

This turned out to be almost a full days thrash!!! I thought things seemed a bit stiff after everything was assembled, so out to the big garage where its about 2 degrees above freezing I went.I pulled off the adjustable pawl wheel from the non sprocket end of the mainshaft and put an 8" v-pulley on it. I disconnected the connecting rod that drives the sawframe up and down, and hooked the sawmill up to a 1/2 HP electric motor that I have as a spare bandsaw motor. I was going to let it run for an hour and "free things up". It ran for about 15 minutes and the clutch seized up. Smoke show from the v-belt. Damn!!! Pulled the clutch off and took it all apart, fully expecting a seized up bearing. It wasn't a seized bearing. The rotating shaft had "picked up" from the front aluminum housing bore and galled bad enough to stop all rotation. After a lot of head scratching and nasty words and big hammer and press work, I got the clutch apart, cleaned up the shaft, cleaned up the aluminum housing bore, greased everything and put it all back together. Then decided "In for a dime, in for a dollar" and changed out the 100 tooth sprag wheel for a 125 tooth sprag wheel (They are change gears out of my lathe). Now I have to go begging at the o-ring supplier and get a pair of .150 cross section o-rings to use as primary drive belts between the Odds and Ends engine and the clutch. I also have to mount my new fuel tank on the Odds and Ends hit and miss engine. Hopefully the weather will start to co-operate soon and the big garage warms up enough for me to set everything up and take a video of sawing a "log" under hit and miss engine power.

aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

I'll be looking forward to that video.

jixxerbill

Well-Known Member

- Joined

- Jan 11, 2013

- Messages

- 114

- Reaction score

- 24

I can't wait to see the video Brian.

Hopefully, this is where I'm going next. I need some warm weather now to get this set up out into my big garage and get it out of my office. Once I get it set up and running, then I can play around with a different blade and maybe different blade angles. I will probably "borrow" some version of Jim Dunmyers Pawl lockout lever. This picture shows the 125 tooth "ragwheel" gear, which was previously 100 tooth. This is to slow the carriage advance down and consequently take some of the load off the engine.

I'm setting here rather perplexed at the moment. The Odds and Ends engine, with its 1" bore, doesn't seem to have sufficient power to run the mill. I have the feeling that the clutch mechanism is still binding when under power, as the smaller engines I have ran the mill quite capably with a direct belt drive to the sawmill. I really had hi hopes for a sawing video this afternoon, but it looks like that isn't going to happen. I know that Jim Dunmyer is building one of these clutches right now from my plans, and I'm sure he won't have a problem with it because his engine is much larger than mine, so even if there is a bit of binding in the clutch a bigger engine will very quickly "wear it in". I have tried to run the mill by getting my engine running, then popping the o-ring drive belts onto it, but when I do it just dies down and gives up on me. I will get to the bottom of this, and I will have a video---just not as soon as I had hoped.

Success is so sweet!!! Sometimes it just takes a while. Here is the video I have been promising for the last 3 months, of the Odds and Ends hit and miss engine I built this past winter, driving the sawmill I designed and built last year, thru the clutch I designed this winter. It is running a new sawblade that Jim Dunmyer sent me. He has built this sawmill and exhibited it at a show in Florida, and done some experimenting to see what blade would cut with the least amount of drag on the engine. The sawmill works like a charm. The new design of clutch seems to work perfectly with no drag at all on the engine, when engaged or disengaged. I will be posting all the details for this clutch on my thread "Clutch---Again". The Odds and Ends engine seems to be working very well. Right at the very end of the video, where it quits going into "miss" mode, the engine had warmed up and was running a bit rich. After I was finished the video I turned the needle in about 1/4 turn, and the engine speeded up at the leaner setting and went back into its hit and miss cycle. I am so happy to have been able to finally post a video showing all these components working so well together. Thanks for all the interest that has been displayed over the winter, as I've fought my way through all this.----Brian

aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

That went really well. I'm surprised at the speed that it went, thought it would be much slower. Nice work Brian!

I cut my first REAL board today!!! Up until now, I have been cutting balsa wood, thinking that my small engines just weren't powerful enough to saw anything tougher. Today I ran out of engineering work about 10:00 A.M. so I decided to turn a piece of spruce to a 1" diameter "log", which my log holder on the sawmill fits. It made one Hell of a mess of my lathe, but the good news is that the sawmill went through it without any hesitation!!! Jim Dunmyer---If you see this take heed. Using a gear reduction and clutch like I show in the previous video, I'm sure even your smaller engines could run your sawmill with no trouble.---Brian

Last edited:

aonemarine

Well-Known Member

- Joined

- Nov 18, 2012

- Messages

- 887

- Reaction score

- 212

Hmm, wonder if it will cut aluminum???

Nel957--The sawmill does indeed work very well. A gentleman from Maine or Minnesota has built a version of it and is running demonstrations of it cutting boards all over USA. Send me your real address to [email protected] and I will send you the pdf files for it.---Brian Rupnow

Similar threads

- Replies

- 61

- Views

- 8K