Hi guys,

Ive been wanting to make a good model dynamo to run with a stationary steam engine.

I dont realy like the kits available from stuarts and pm, i just dont like the price of a modern motor guts in a fancy shell.

I have searched the internet for some plans but had no luck so im going to make my own from scratch.

Il make a full log of the design and build on here as it would be somthing i would want to see myself and i hope it helps somone or someone can help me along the way.

The more i searched the internet the more i become confused aboit generators, so im just starting from the basics i do know and see what works best along the way regarding wiring and magnet arangements.

Il try and keep it as simple as possible and add some cosmetc character to the final model with some nice castings.

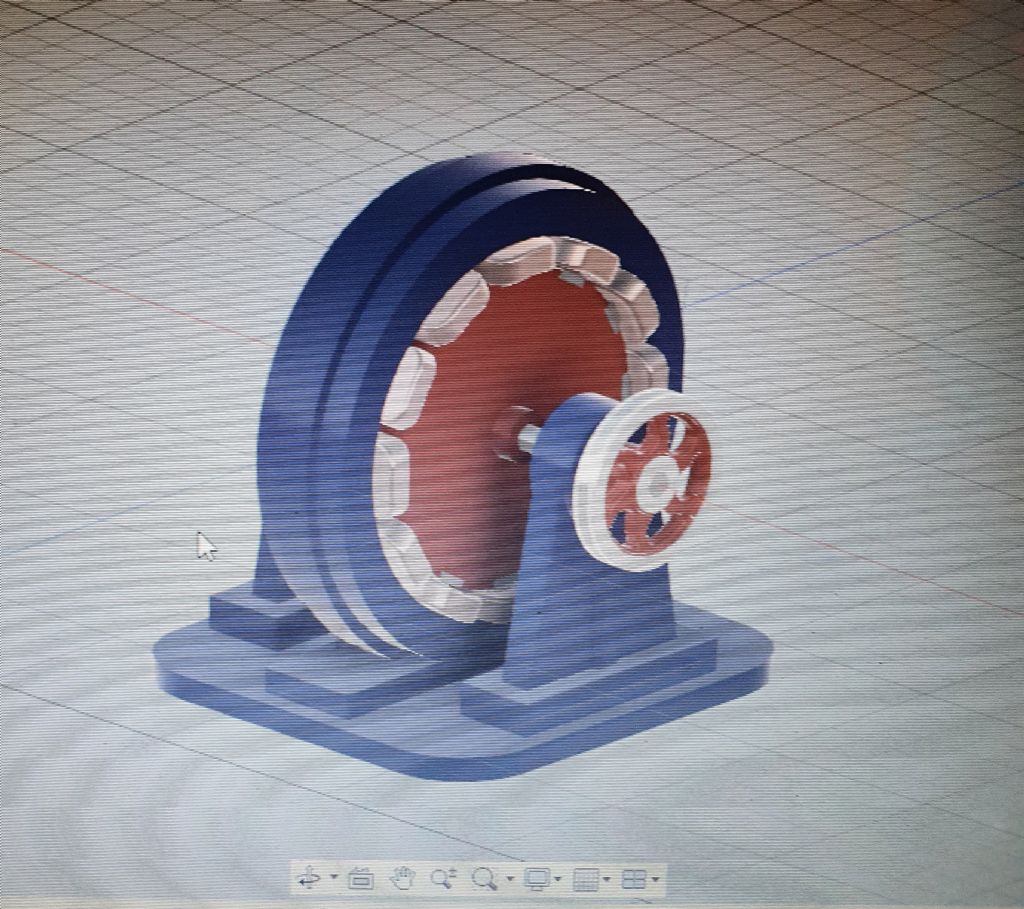

The model will have a stator of 12 fixed windings and i think a rotor with 16 pole magnets.

The first prototype is just being printed in the 3d printer so picks to come soon.

Ive been wanting to make a good model dynamo to run with a stationary steam engine.

I dont realy like the kits available from stuarts and pm, i just dont like the price of a modern motor guts in a fancy shell.

I have searched the internet for some plans but had no luck so im going to make my own from scratch.

Il make a full log of the design and build on here as it would be somthing i would want to see myself and i hope it helps somone or someone can help me along the way.

The more i searched the internet the more i become confused aboit generators, so im just starting from the basics i do know and see what works best along the way regarding wiring and magnet arangements.

Il try and keep it as simple as possible and add some cosmetc character to the final model with some nice castings.

The model will have a stator of 12 fixed windings and i think a rotor with 16 pole magnets.

The first prototype is just being printed in the 3d printer so picks to come soon.