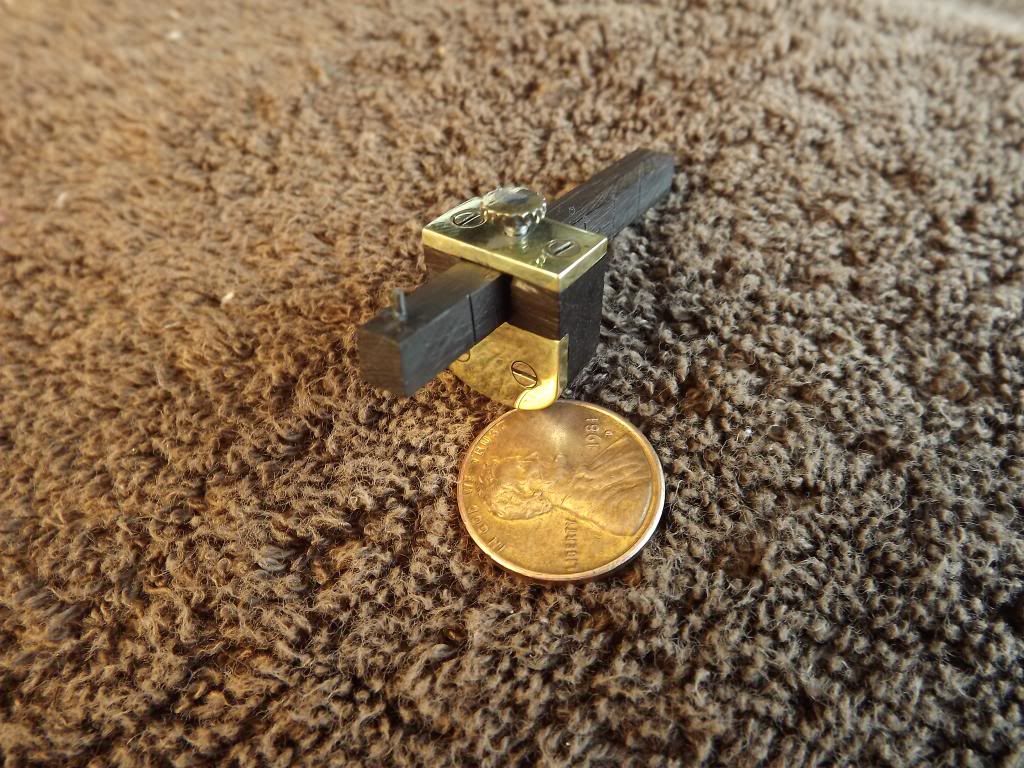

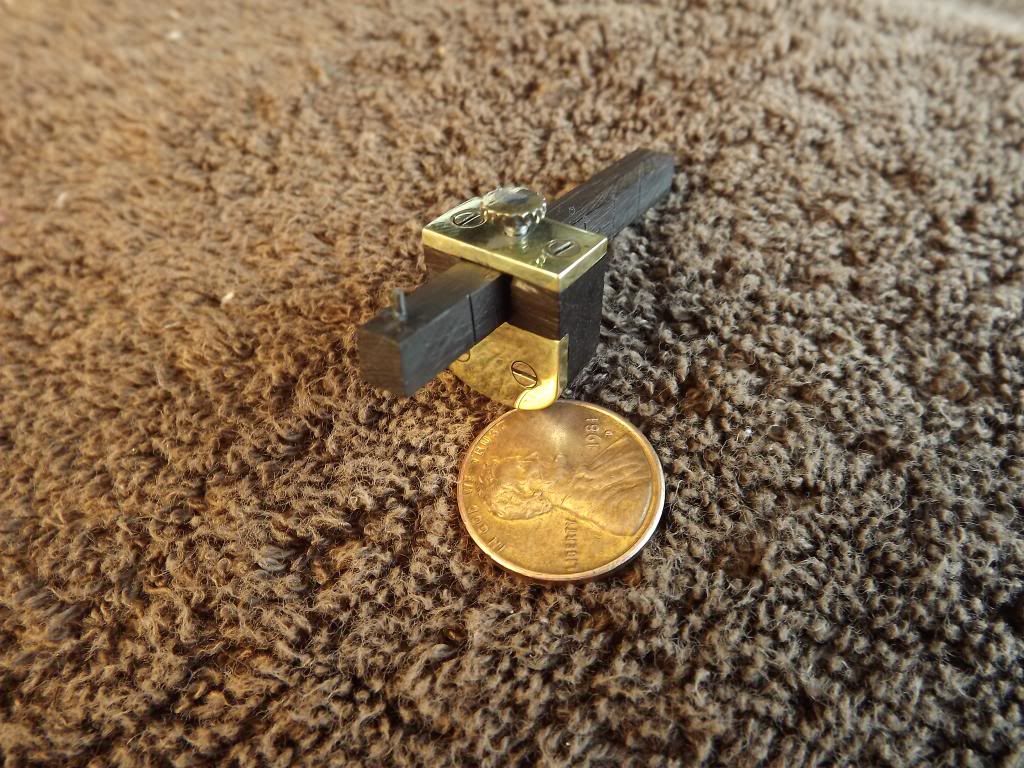

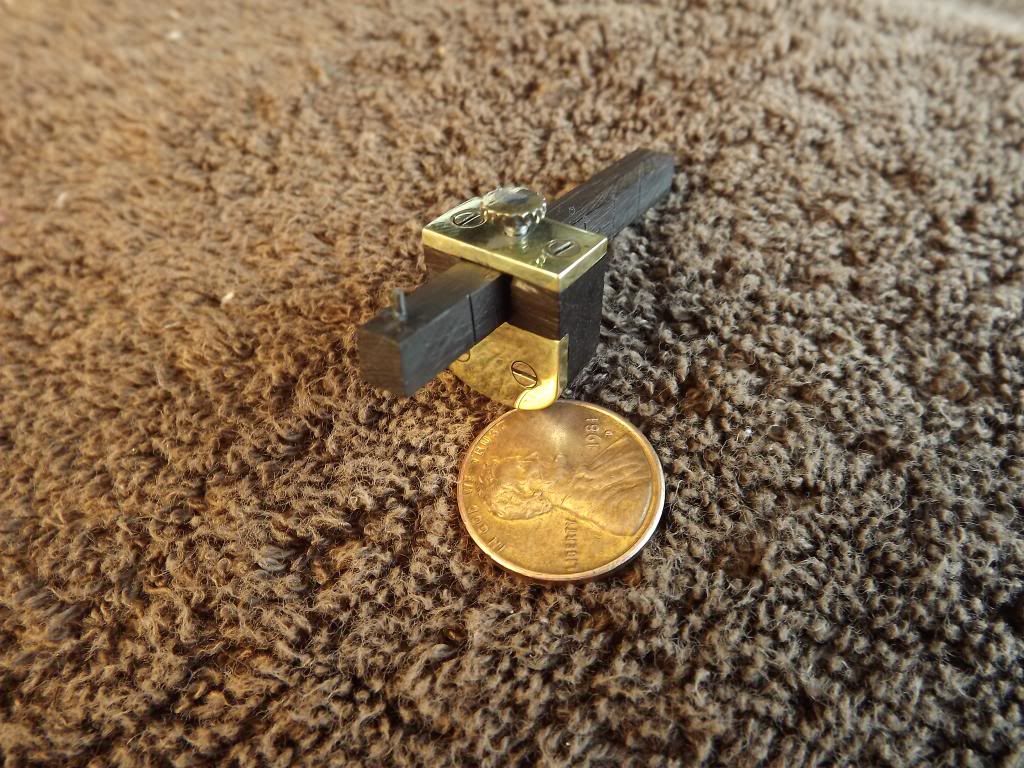

Thanks DPowell. I have employed two different processes to build my planes - the metal parts. The wood parts are carved the same way for both. Process 1 is the lost wax casting method in which a form of the plane is built of wax with investment (a plaster of Paris mix) surrounding wax model in a container. The wax is then melted out leaving a cavity in the shape of the wax model in the plaster mold which is then cured in high heat, and molten metal is poared into the cavity yielding a solid metal version of the original wax model which is then finely finished and polished and the handle and knob are bolted on. In the other process the various pieces are cut from sheet stock then silver soldered together in their respective place. then the piece is filed, sanded and polished, and the wood parts are attached. Each process has its advantages and difficulties. A Rubber mold can be made of either, and by injecting wax into the cavity, wax patterns can result allowing process 1 to be repeated for any number of copies. Sorry this got so wordy. I'll try to do a pictoral build documentation. Ralph

9