C

chiliviking

Guest

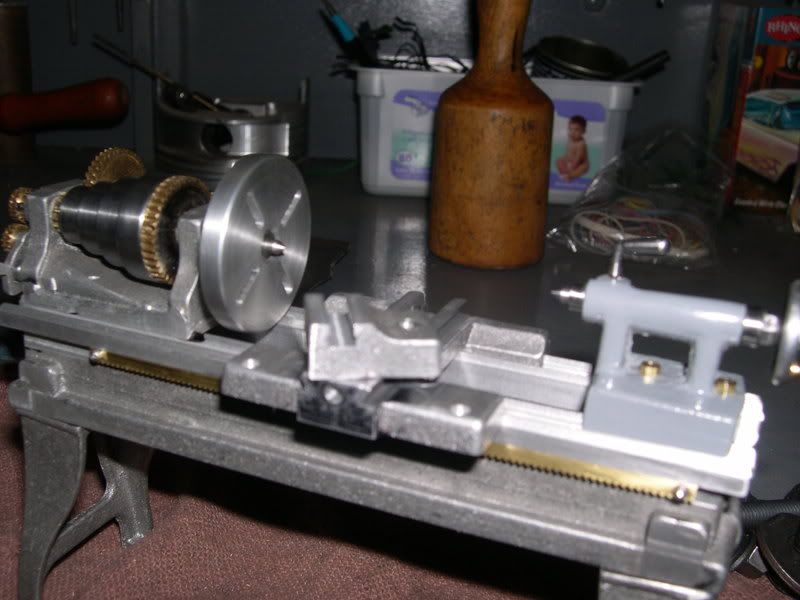

I need to machine the T-slot for the tool post on my PM lathe project. I assumed I was going to use a woodruff key cutter for this however looking at the specs. on them even the smallest is 1/4" dia. Way too big. The slot for the tool post needs to be .188 x .070 and .156 at the skinny part of the T-slot. Obviously the .156 part is a straight forward milling job with common tooling but what is available to mill out the .188 X .070 part at the bottom. The length of the T-slot is approx. 5/8"

I have thought of some solutions but none that seem practical. Any ideas anyone?

I have thought of some solutions but none that seem practical. Any ideas anyone?