You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mini Bike

- Thread starter stevehuckss396

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Thanks. I now have to do a mountian of work to get the motor going.

Anybody know of a good way to coil wire so I can build cables. I found a source for spring tubes but the minimum order is 650 bucks at 17 bucks a foot. That aint happening.

Anybody know of a good way to coil wire so I can build cables. I found a source for spring tubes but the minimum order is 650 bucks at 17 bucks a foot. That aint happening.

Hello Steve,

Are the cables for the brakes/throttle/clutch?

If so, you can get some very small control cables for RC aircraft from any decent hobby shop.

The cable itself can be as small as .032" (0.8mm) diameter with a tube (from memory) about .08" or .1" (2 - 2.5mm), so you should have no problem getting a scale size.

The minimum bending radius for the smallest control cables is about 1.5". The tube is yellow unfortunately but probably wouldn't be too hard to paint black.

I have used this stuff for years and it is very good. I've never used the supplied clevises, I make my own (smaller) fittings and soft-solder direct to the cable.

Check the Sullivan website, their products have been available at every hobby store I have ever visited.

http://www.sullivanproducts.com/GoldnRodMainFrame.htm

Scroll down past the 'Nylon' type to 'Steel Cable Type', note that the cable is steel(stainless) but is plated for easy soft-soldering.

Edit:

Sorry, forgot to mention there is also Du-bro brand pushrods(example picture of 'Micro 30 system' with the clear tube)... same thing, every hobby store I have ever been to stocks this stuff.

http://shop.dubro.com/p/30-micro2-pushrod-system-2-pkg

I can't comment on the Du-Bro gear as I have always used Sullivan, but I wouldn't expect it to be very different. It is a solid rod tho so may not have the bending radius that the Sullivan cable has.

Edit #2:

Also forgot to mention that these cables work equally well in 'push' operation as they do with 'pull'. Model aircraft can put phenominal loads on these cables and I have never had a problem yet.

When the bending radius is pretty tight I usually put a couple of drops of a light silicon or Teflon oil on the cable before pushing it into the tube.

Are the cables for the brakes/throttle/clutch?

If so, you can get some very small control cables for RC aircraft from any decent hobby shop.

The cable itself can be as small as .032" (0.8mm) diameter with a tube (from memory) about .08" or .1" (2 - 2.5mm), so you should have no problem getting a scale size.

The minimum bending radius for the smallest control cables is about 1.5". The tube is yellow unfortunately but probably wouldn't be too hard to paint black.

I have used this stuff for years and it is very good. I've never used the supplied clevises, I make my own (smaller) fittings and soft-solder direct to the cable.

Check the Sullivan website, their products have been available at every hobby store I have ever visited.

http://www.sullivanproducts.com/GoldnRodMainFrame.htm

Scroll down past the 'Nylon' type to 'Steel Cable Type', note that the cable is steel(stainless) but is plated for easy soft-soldering.

Edit:

Sorry, forgot to mention there is also Du-bro brand pushrods(example picture of 'Micro 30 system' with the clear tube)... same thing, every hobby store I have ever been to stocks this stuff.

http://shop.dubro.com/p/30-micro2-pushrod-system-2-pkg

I can't comment on the Du-Bro gear as I have always used Sullivan, but I wouldn't expect it to be very different. It is a solid rod tho so may not have the bending radius that the Sullivan cable has.

Edit #2:

Also forgot to mention that these cables work equally well in 'push' operation as they do with 'pull'. Model aircraft can put phenominal loads on these cables and I have never had a problem yet.

When the bending radius is pretty tight I usually put a couple of drops of a light silicon or Teflon oil on the cable before pushing it into the tube.

Last edited:

Cogsy

Well-Known Member

I can't help with outer tubing, but wire fishing trace is available in a range of strengths/thicknesses. There are two types commonly available. One type is just single strand wire and wouldn't be suitable, but the other is very finely braided wire. Should look very realistic.

P.S. I haven't commented yet, but the bike looks great!

P.S. I haven't commented yet, but the bike looks great!

Sounds promising. I'll check into it.

Thanks to both of you for the help.

Thanks to both of you for the help.

johnny1320

Middle aged Member

- Joined

- May 15, 2013

- Messages

- 149

- Reaction score

- 16

How about using black shrink tube for the casing, heat shrink it on a wire and slide it off.

Lakc

Well-Known Member

Yep, local hobby shop, dubro or sulivan. Dont know whats closest for you, I only hit the east side hobby shops once in my life.  Nankin at 9mile and farmington has them in stock.

Nankin at 9mile and farmington has them in stock.

Found a little time, made a little piece

vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

Wow!

What a great idea...just saw this today.

I'll be watching the rest of this build...very cool.

What a great idea...just saw this today.

I'll be watching the rest of this build...very cool.

t.l.a.r. eng

Well-Known Member

- Joined

- Feb 9, 2009

- Messages

- 81

- Reaction score

- 14

Was really hoping this project would continue! The suspense is killing me!

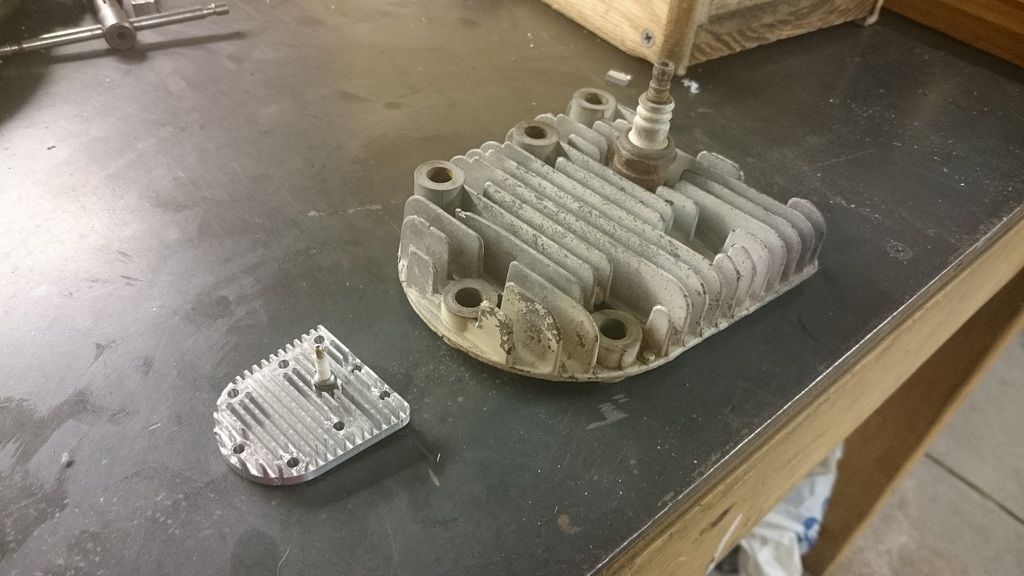

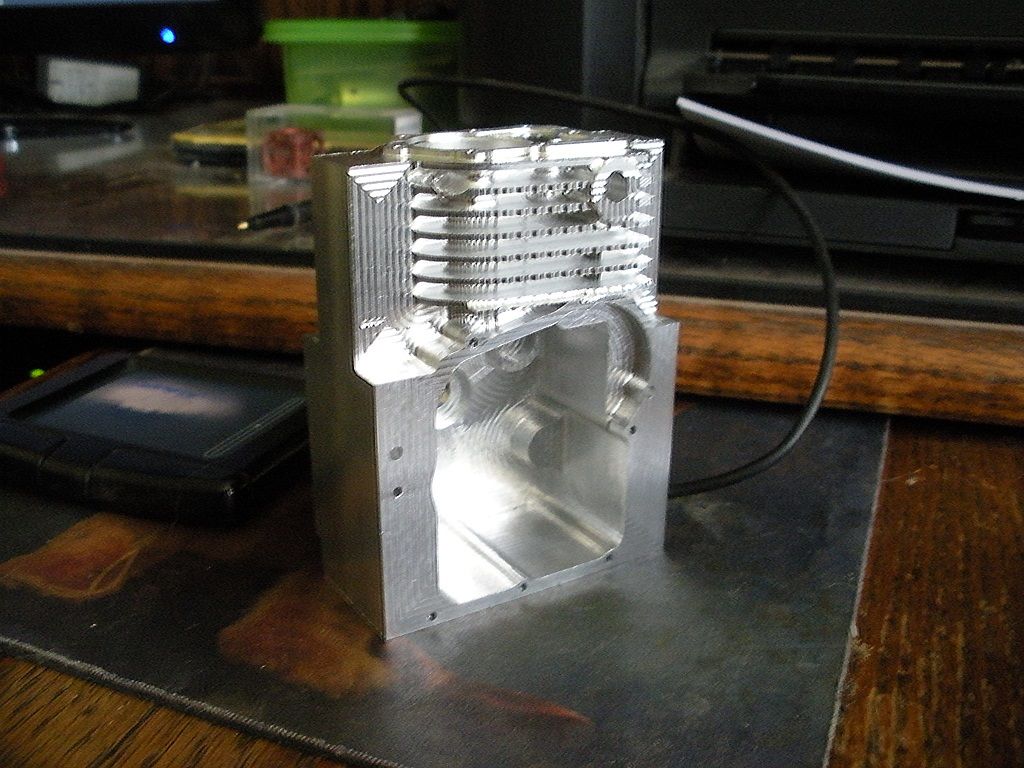

Sometimes when something is scaled down some of the detail will be lost to make the piece doable. The original block has 8 fins. This one will only have 7. I had to sacrifice a fin to allow room for a cutter with enough reach to get to the depth required to cut out the fins. Should know if it worked in a few days.

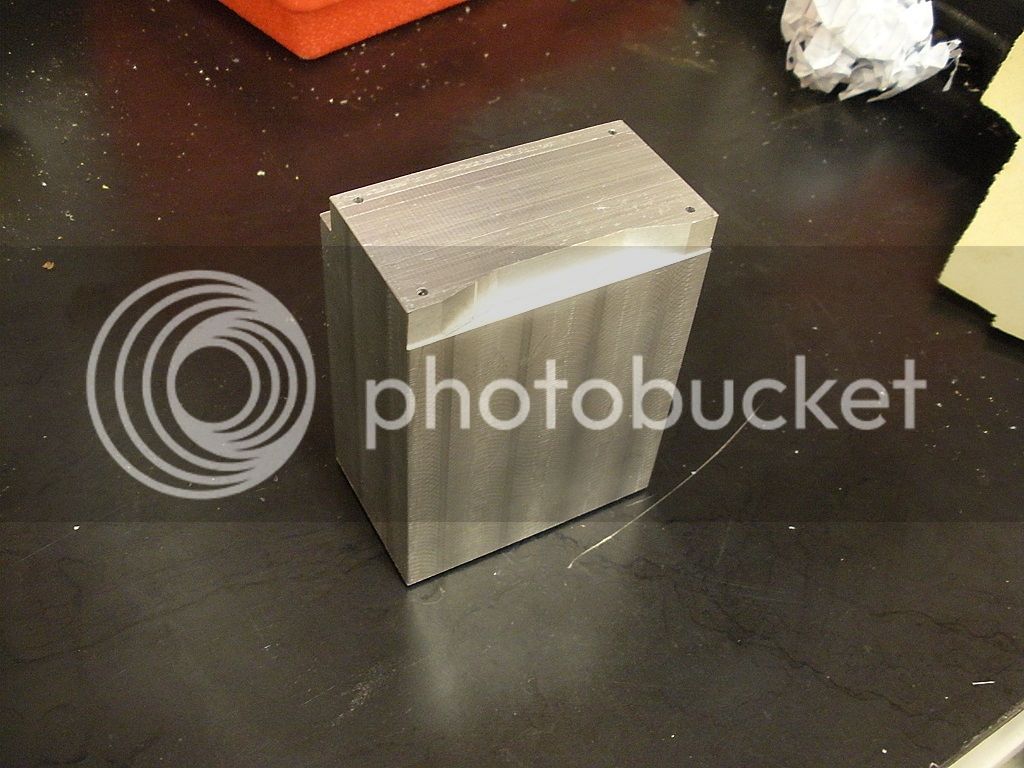

Little bit more.

Little bit more.

Last edited:

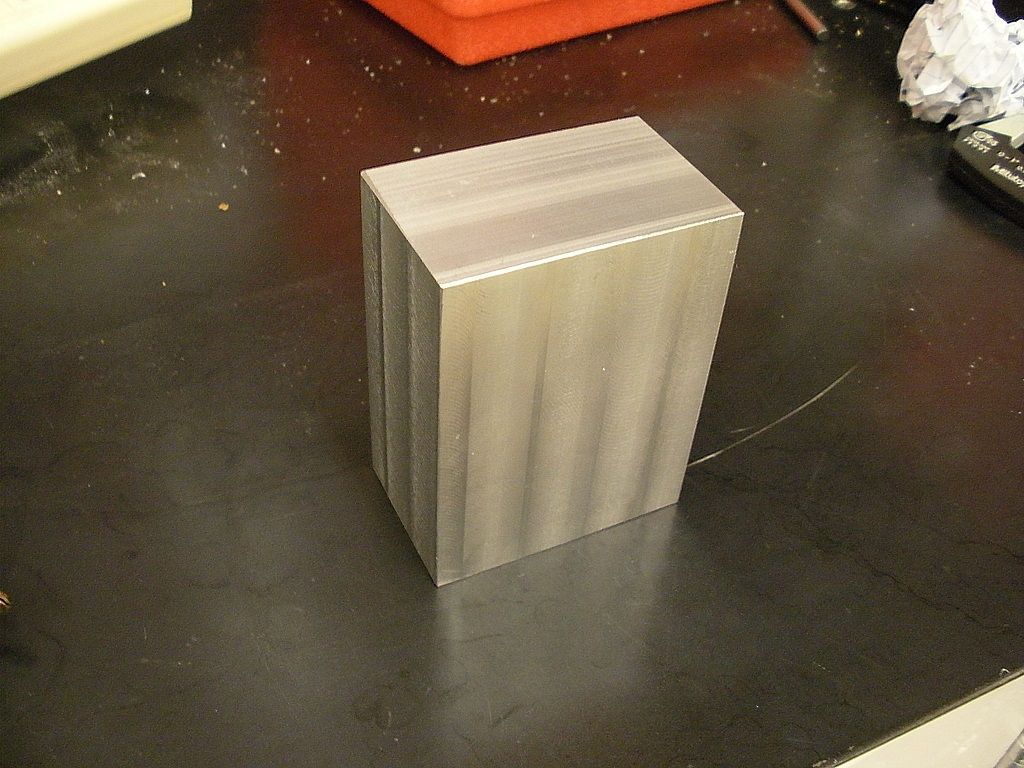

Tested some code on a test block. Not bad. I added some lines to see if I can smooth out the shelf under the fins. We shall see.

Thanks Art. I hope to do the opposite side tomorrow.

RiekieRhino

Member

- Joined

- May 25, 2015

- Messages

- 20

- Reaction score

- 2

This is looking great. Can't wait to see the finish project

This project is looking really smart! Glad its started up again.

You've probably already said what CAM software you're using but can I ask again...

Its projects like this that get be fired up.

R

Alibre to model my engines.

CamBam does all the magic. Can't say enough about how well it works.

Mach3 runs the mill. It does all the other magic.

Side 2 code for the mill is tested. I had a little crash so the finishing passes were not complete but the problem has been corrected and I'm on to side 3. I guess that's why we test. When the code is complete I am going to try to make 3 cases. There will be about 15 hours each to cut so I think the extra debug time is worth it.

canadianhorsepower

Well-Known Member

- Joined

- Oct 22, 2011

- Messages

- 1,671

- Reaction score

- 324

There will be about 15 hours each to cut so I think the extra debug time is worth it.

Great Steve

How can someone NOT like this Thm:Thm:Thm:

cheers

Similar threads

- Replies

- 151

- Views

- 28K