hi guys, sorry for the lack of replies im back at uni now and that has understandably taken priority.

bez, thankyou for that very informative post regarding bronze compositions :bow:, i was very interested in reading how little the lead percentage effected the melting temperature of bronze. though nothing should surprize me in the world of metalurgy it is such a very large field of science(??? or feild of its own)!!!!

having being thinking about this for what has been probably been close to a month and a half, the concept of me making my own alloy while sounding appealing probably its going to be the best option in the long run. the only reason i was considering it is because of the relatively large amount of copper i have (found 40m worth of old mains wiring that had been dug up from an old clubhouse, equated to roughly 20kg of copper ;D) but i figure i may as well use what bronze scrap i do have laying about.

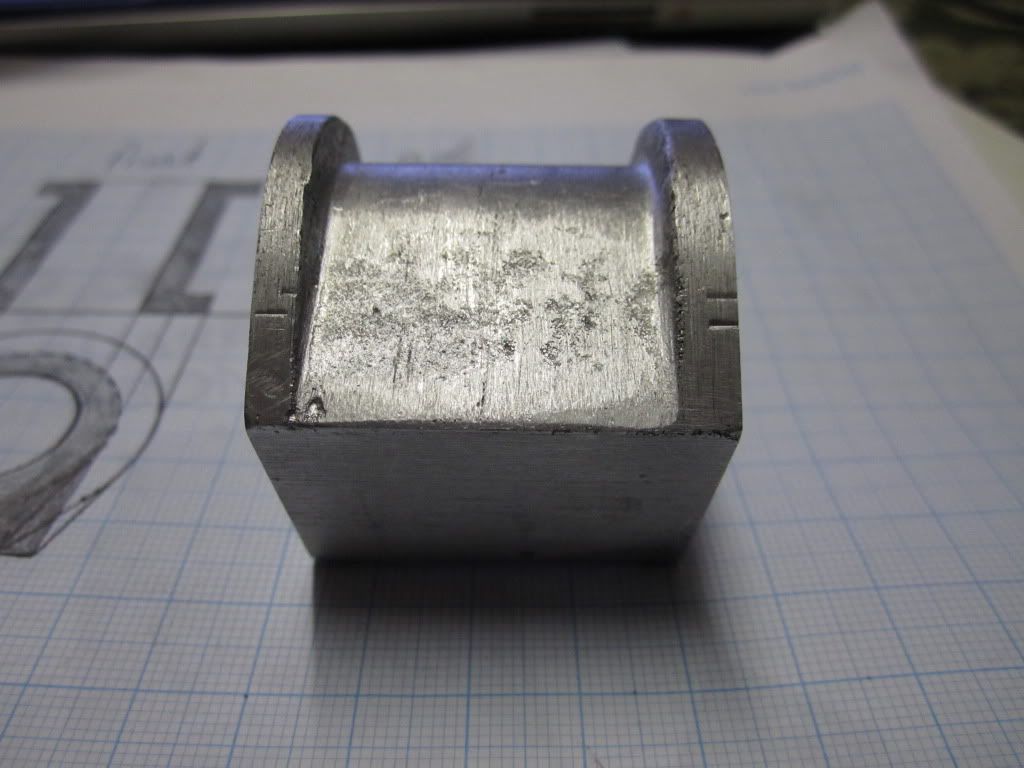

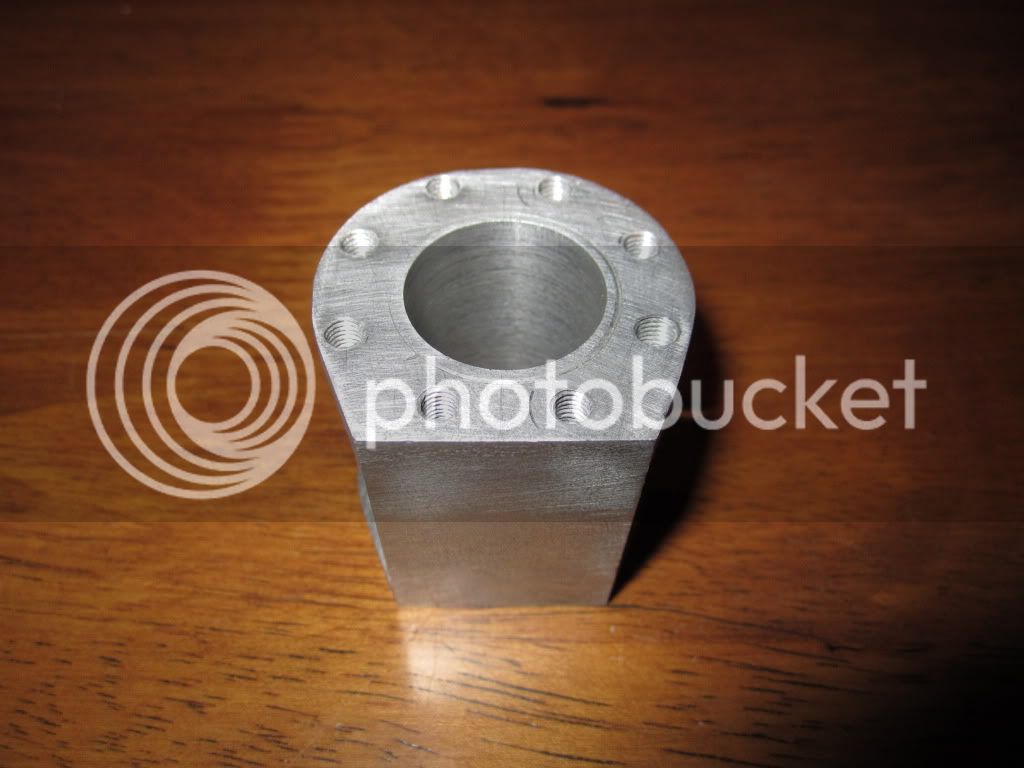

as for progress ive made the wooden pattern for the base of the engine, im rather happy with how it looks so far considering im designing this guy myself. ive also done small amounts of turning on the other parts after work on my bosses lathe as well as designs for the other parts to come.

i also tried my hand at fabrcating a crank shaft, in the end it was a complete failure BUT in a way i wont it to be ive learnt so very much from it that im sure when i finally get around to making one for this project it will come together and work without any (touch wood) problems.

i spose now all i need to do is buy my self a nice lathe (which i am currently "trying" to save for, uni isnt very understanding in that prospect :-[) and this little project of mine may one day come together :big:.

p.s. if anyone knows of a goodish lathe for a basicly complete noivice around the $1000au price range suggestions would be so so very much apprieciated. ive run into what seems to be something a lot of beginners run into when trying to choose a new machine, doing lots of research but as a result feeling completely overwhelmed and more confused then when you started, the best advise i can figure would deffinently come from some of the stupidly wise and experienced guys here

.

cheers kye.