The Bugster has been jumping up and down on the PM channel for me to post the results of my nocturnal design session. I'll admit to delaying a bit in doing that, just to watch him oscillate.

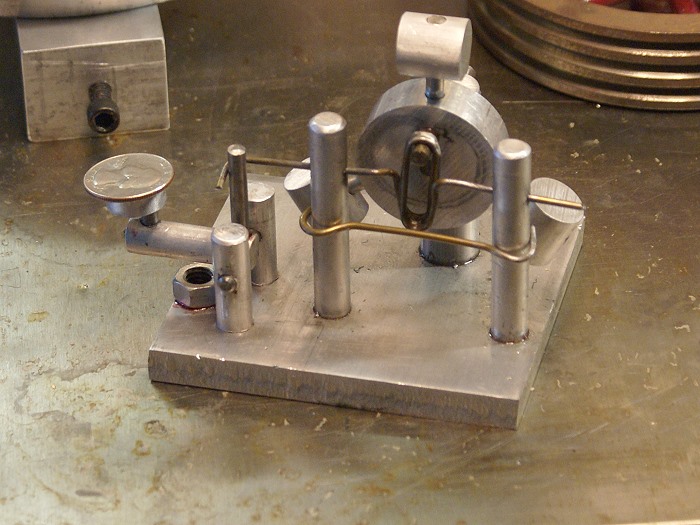

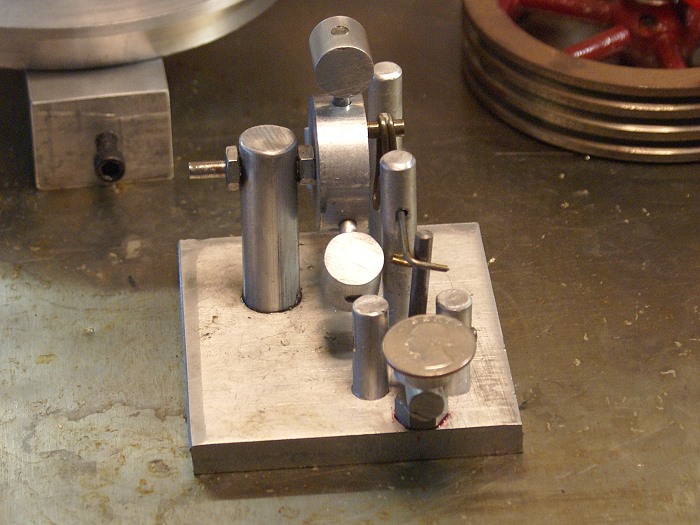

I took a different tack from the get go, so my little engine is not as far out there as The finger food entry and my shrubs are still my friends. I stuck with metal, but I stayed well within the rules, even avoiding using threaded fasteners almost completely. After 4 hours and 20 minutes, I had a "working" engine.... right up to the moment that I got loctite happy and accidentally glued the treadle pivot solid. So, I'm taking a mulligan and claiming another 15 minute penalty.

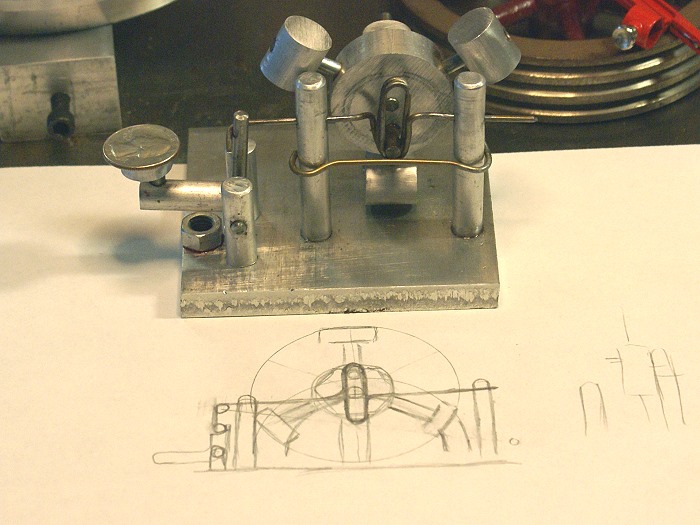

The design is based on the "Scotch Yoke" style of crank mechanism. The hammers on the flywheel are there to add a bit more mass to it so it will rotate a bit better on its own stored energy. If I were doing things again, I'd increase the diameter and use even heavier material for the hammers.

Running this little beggar is different from the normal crank style engine. In fact its almost as tricky as riding a unicycle. Two things come into play here. The flat spots in a Scotch Yoke configuration are just that... physical flat spots. You have to pre-position the flywheel to get it to start. The other oddity is that unlike the standard crank, you can only stroke the treadle on every other stroke, making establishing a rhythm trick as the dickens. If you stroke it out of sequence, it either stops the flywheel or it reverses the direction instantly.

Truthfully, the delay in posting was not just for teasing John. I'm not blessed with a high level of natural rhythm and trust me....no one really wants to see what I pass off as dancing. That made learning the trick to making this darned thing run more than a couple of strokes a right challenge. I'll try to figure out the video thing over the next day or so and see if my new phone will show things in action.

Enough rambling... Below is my "Quarter Pounder", formerly called "Pud".

Steve

;D

;D