Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

While cleaning up I found some Bronze that I had squirreled a way to build the Cyclone. I'm calling this engine the Mega Cyclone because I'm making this engine twice as big as the plans call for. I'll be changing a few Items to make it easier to build. But most of the parts will be as drawn. Just bigger ) This engine is neat because the engine spins and the crank is stationary. I have a 19" 3 bladed prop that I'll fit to the engine. The pistons will be 1.250" in dia.

) This engine is neat because the engine spins and the crank is stationary. I have a 19" 3 bladed prop that I'll fit to the engine. The pistons will be 1.250" in dia.

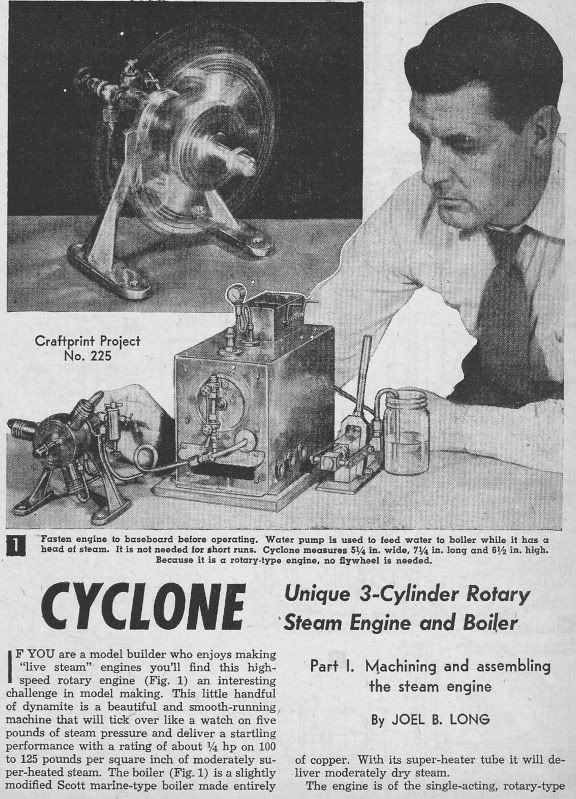

Here Is the first page from the plans.

I have the crank valve turned. I'll mill the steam ports into it. The plans call for the ports to be made from a couple pieces silver soldered in. I think this will be easier? I left the bearing surfaces a few tho. Bigger and I'll turn them to size after the ports are milled.

Here are the parts I managed to get turned today. The crank bearing housing will get a piece of cast iron pressed into it for the bearing.

I'll start on the crank case next. These pieces will have a fair amount of mill work done to them.

Here Is the first page from the plans.

I have the crank valve turned. I'll mill the steam ports into it. The plans call for the ports to be made from a couple pieces silver soldered in. I think this will be easier? I left the bearing surfaces a few tho. Bigger and I'll turn them to size after the ports are milled.

Here are the parts I managed to get turned today. The crank bearing housing will get a piece of cast iron pressed into it for the bearing.

I'll start on the crank case next. These pieces will have a fair amount of mill work done to them.