Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Hi All,

Well here we go again.

I wondered should this be.... "Bore along with Bob" or "Metal Mayhem with Maryak" :

Take your pick.

. As it is my design a running engine at the end will be a real bonus.

. As it is my design a running engine at the end will be a real bonus.

For those who have been following the marking out thread, today's effort may have some relevance.

The expensive lumps from which M10 will be attempted.

The setup for marking out, the marking out table is a piece of plate glass.

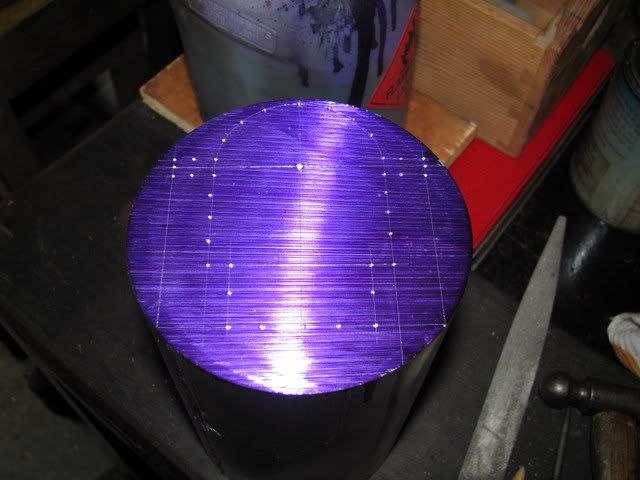

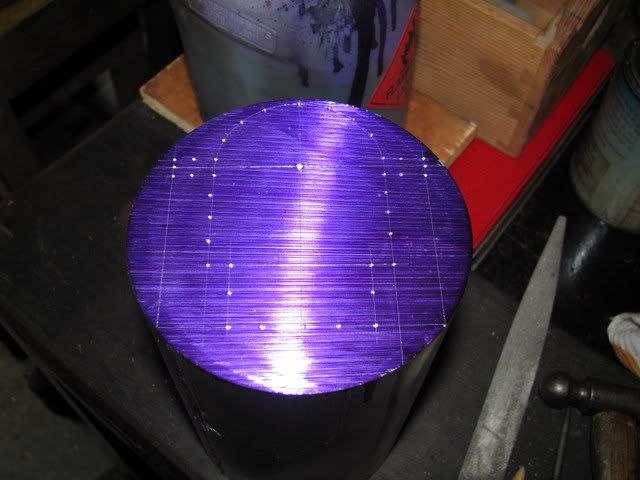

The end elevation of the drawing transferred to the metal. The profile centre pops are so I don't lose all my hard work when throwing it from bench to lathe to mill and back again.

The cut marks so I can hack off a usable lump.

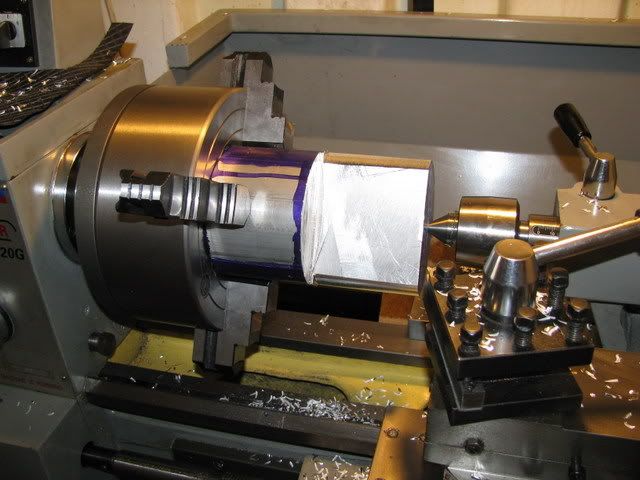

Hacking off said usable lump.

The bit which I hope will be the crankcase ready for setting up in the lathe.

And that brings me to the end of day 1.

Best Regards

Bob

Well here we go again.

I wondered should this be.... "Bore along with Bob" or "Metal Mayhem with Maryak" :

Take your pick.

For those who have been following the marking out thread, today's effort may have some relevance.

The expensive lumps from which M10 will be attempted.

The setup for marking out, the marking out table is a piece of plate glass.

The end elevation of the drawing transferred to the metal. The profile centre pops are so I don't lose all my hard work when throwing it from bench to lathe to mill and back again.

The cut marks so I can hack off a usable lump.

Hacking off said usable lump.

The bit which I hope will be the crankcase ready for setting up in the lathe.

And that brings me to the end of day 1.

Best Regards

Bob