Tony Bird

Senior Member

Hi,

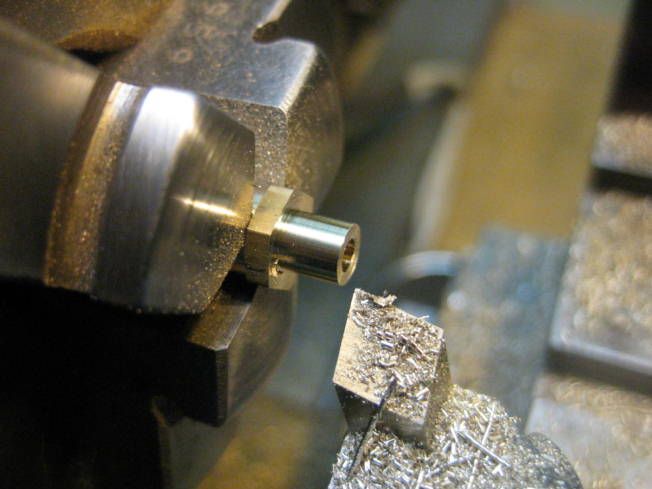

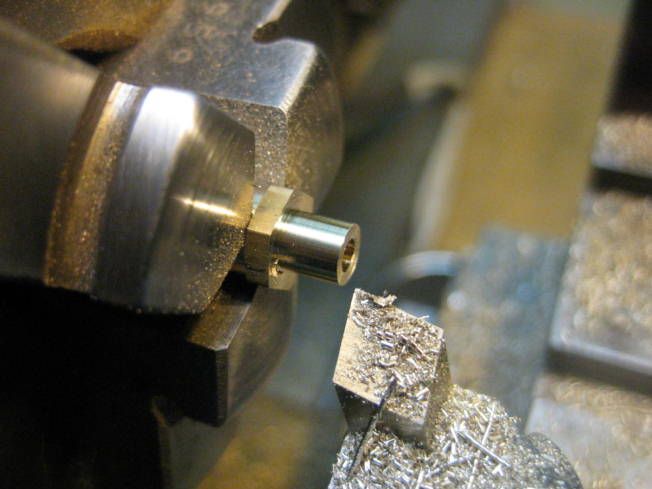

Having constructed several boiler, fittings for them need to be made. Normaly these fittings are made in batches but none are left. Some months ago I bought an inexpensive Chinese tail stock turret. The last time I used one was when I was an apprentice! The turret was modified to suit my Myford lathe and has had some use producing boiler bushes and gas regulator valves which now means that it is now up and running. Yesterday a start was made making the bodies for safety valves, this is the first time that all 6 stations of the turret have needed to be used. The turret though fairly cheap to buy costs a lot more to fill ith Jacob chucks and tool holders. I have found the turret very useful and quick but I make all of my own fittings usually in multipules. The following photographs show the sequence used making 12 safety valve bodies each body took about 10 minutes to make and the set up of the turret about 40 minutes.

Turret set up.

Marked out.

Centre drill.

Tapping drill.

Drill for steam entry.

Drill to make bottom of hole flat.

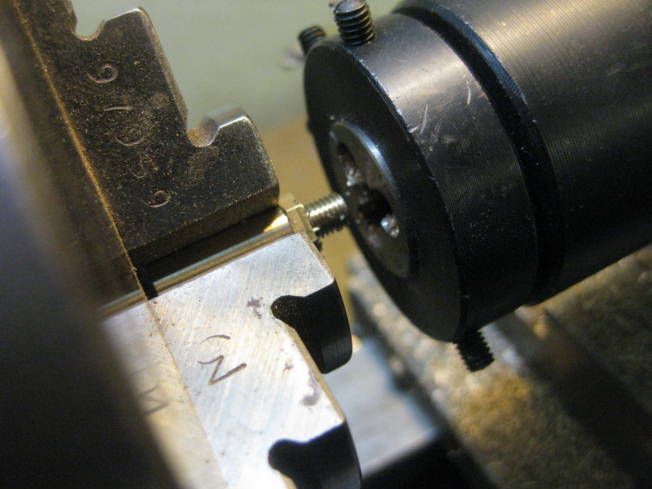

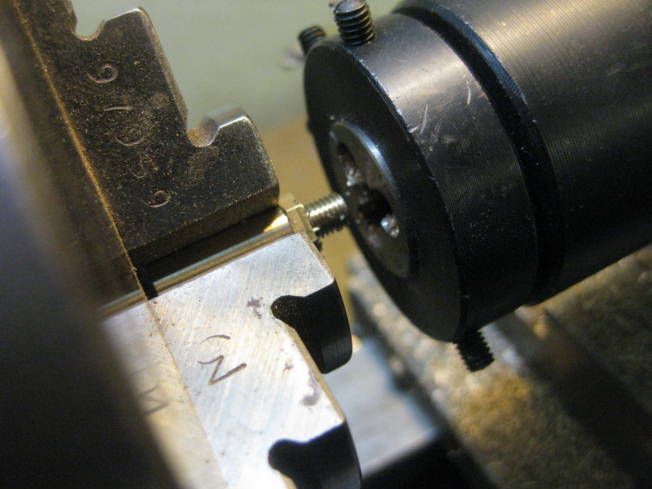

Tapping.

Turning sholder.

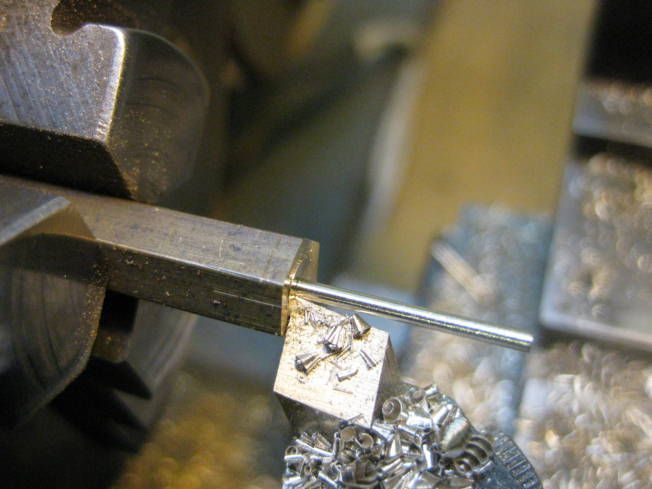

Parting off.

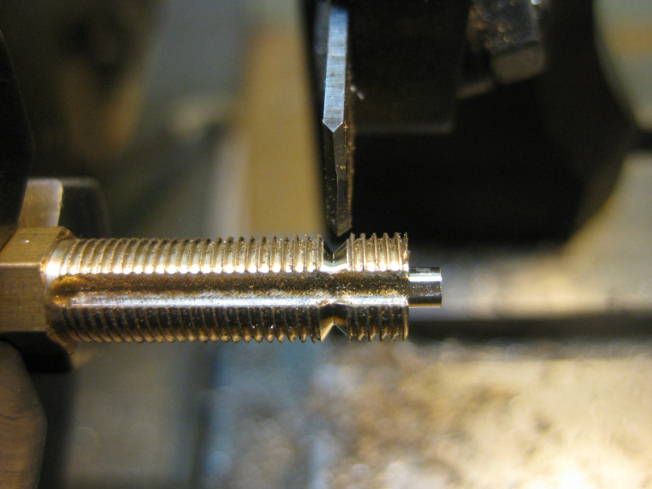

Turning shoulder for thread.

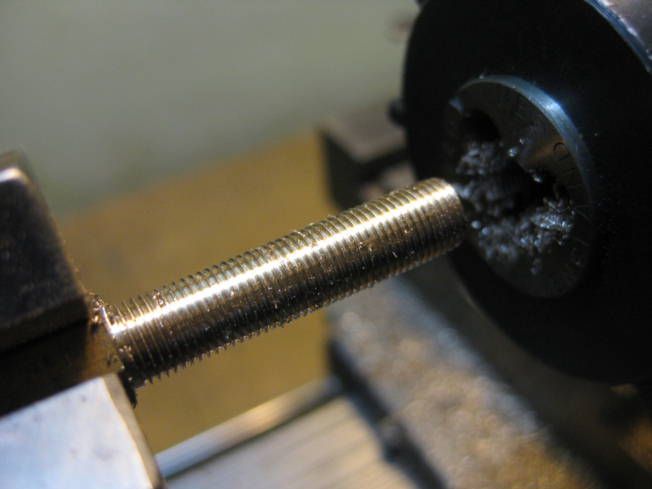

Threading.

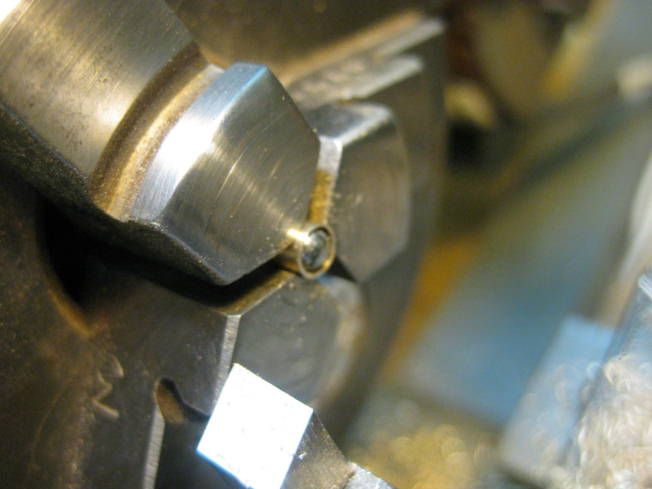

Finished.

For those interested the internal thread is 1/4"x 40tpi the exrernal 3/16"x 40tpi. With the bodies finished its the srew that holds the spring in next.

Regards Tony.

Having constructed several boiler, fittings for them need to be made. Normaly these fittings are made in batches but none are left. Some months ago I bought an inexpensive Chinese tail stock turret. The last time I used one was when I was an apprentice! The turret was modified to suit my Myford lathe and has had some use producing boiler bushes and gas regulator valves which now means that it is now up and running. Yesterday a start was made making the bodies for safety valves, this is the first time that all 6 stations of the turret have needed to be used. The turret though fairly cheap to buy costs a lot more to fill ith Jacob chucks and tool holders. I have found the turret very useful and quick but I make all of my own fittings usually in multipules. The following photographs show the sequence used making 12 safety valve bodies each body took about 10 minutes to make and the set up of the turret about 40 minutes.

Turret set up.

Marked out.

Centre drill.

Tapping drill.

Drill for steam entry.

Drill to make bottom of hole flat.

Tapping.

Turning sholder.

Parting off.

Turning shoulder for thread.

Threading.

Finished.

For those interested the internal thread is 1/4"x 40tpi the exrernal 3/16"x 40tpi. With the bodies finished its the srew that holds the spring in next.

Regards Tony.