deere_x475guy

Well-Known Member

Hi everyone...it's me again.

No heart feelings to the purists in the group but I once again used Marv's programs to help me figure the OD of the gear I needed and dividing plate I needed. I don't use this math enough to remember it, plain and simple. And the way my memory is anymore even if I used it once a week I would probably forget it. So the fastest way for me to solve this math is to open the folder I have on my desk top, select the program I want to run and punch in the numbers. If you don't have Marv's programs the calculation for the gear OD can be found with a search on the net as can the math for the dividing plate to use. I am using an involute gear cutter with a dividing head. As others have posted here you can make your own cutter and I think you can probably use a rotary table in place of the dividing head. If you know of other ways to do this please feel free to post to this thread if you want to. This is a place for all of us to share our knowledge and our projects. Please keep these two quotes in mind when your posting..

And:

Now..on with the pics.. ;D

First is a screen shot of the gear diameter results from Marv's "GearSpur" program.

I entered zero for the diameter (cause that was the unknown) ;D, 13 for the number of teeth and 20 for the DP because that is the DP of the cutter I have. As you can see the OD is .75, also the whole depth is .110. This means I will cut .110 deep for each tooth. There is also a lot of other info in there but I want to get this posted sometime this evening ;D so if you want to know what the other numbers mean just ask me... ;D ;D

Next I wanted to find out what plate to use in the dividing head. Mine came with 3 different plates.

I told the program I wanted 13 divisions. The results showed to use a 39 hole plate and doing 3 full cranks plus 3 holes. I have added a video that will show using the dividing head. Hopefully you will be able to see the sector arms being used to help me keep track of the 3 holes I need to go after the 3 full turns.

[youtube=425,350]http://www.youtube.com/v/2SCHS-sUA24&rel=1http://www.youtube.com/v/2SCHS-sUA24&rel=1[/youtube]

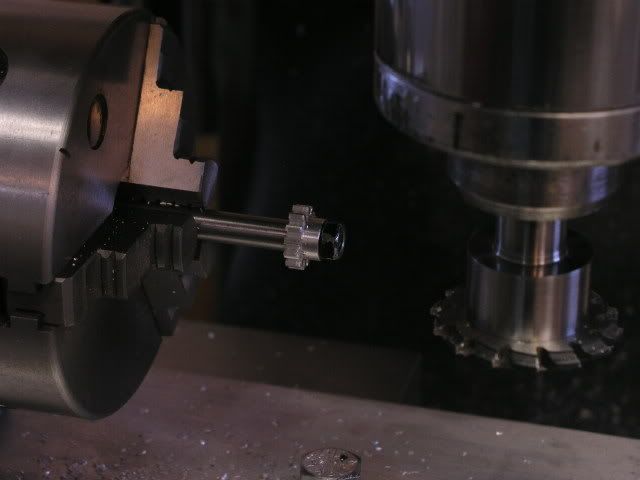

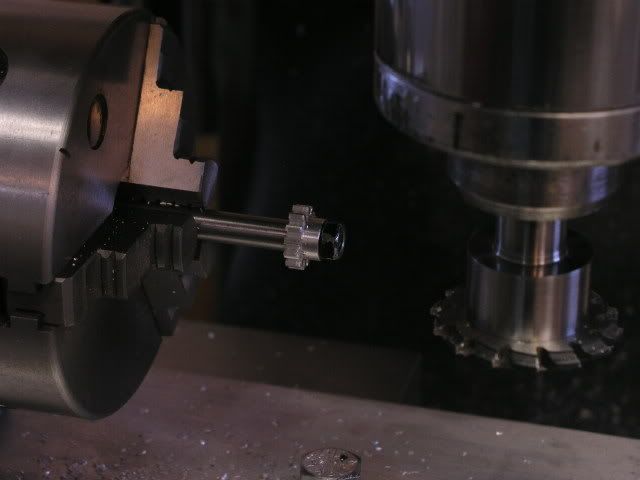

Here is a shot of the gear blank mounted in the arbor. I was conservative with the depth of each cut and only took around .025 per pass.

Here is the finished gear. It is going to run with one I made about 2 years ago when I was learning how to do this.

All normal disclaimers apply

No heart feelings to the purists in the group but I once again used Marv's programs to help me figure the OD of the gear I needed and dividing plate I needed. I don't use this math enough to remember it, plain and simple. And the way my memory is anymore even if I used it once a week I would probably forget it. So the fastest way for me to solve this math is to open the folder I have on my desk top, select the program I want to run and punch in the numbers. If you don't have Marv's programs the calculation for the gear OD can be found with a search on the net as can the math for the dividing plate to use. I am using an involute gear cutter with a dividing head. As others have posted here you can make your own cutter and I think you can probably use a rotary table in place of the dividing head. If you know of other ways to do this please feel free to post to this thread if you want to. This is a place for all of us to share our knowledge and our projects. Please keep these two quotes in mind when your posting..

Borrowed from a post Rick placedWhen someone throws an idea in the fire and it flairs into something more

that can teach an old dog like me a new trick, I see it as a positive event.

And:

Borrowed from a post Marv placedEach of us has a favorite method but that is not license to denigrate other ways to do the job.

Now..on with the pics.. ;D

First is a screen shot of the gear diameter results from Marv's "GearSpur" program.

I entered zero for the diameter (cause that was the unknown) ;D, 13 for the number of teeth and 20 for the DP because that is the DP of the cutter I have. As you can see the OD is .75, also the whole depth is .110. This means I will cut .110 deep for each tooth. There is also a lot of other info in there but I want to get this posted sometime this evening ;D so if you want to know what the other numbers mean just ask me... ;D ;D

Next I wanted to find out what plate to use in the dividing head. Mine came with 3 different plates.

I told the program I wanted 13 divisions. The results showed to use a 39 hole plate and doing 3 full cranks plus 3 holes. I have added a video that will show using the dividing head. Hopefully you will be able to see the sector arms being used to help me keep track of the 3 holes I need to go after the 3 full turns.

[youtube=425,350]http://www.youtube.com/v/2SCHS-sUA24&rel=1http://www.youtube.com/v/2SCHS-sUA24&rel=1[/youtube]

Here is a shot of the gear blank mounted in the arbor. I was conservative with the depth of each cut and only took around .025 per pass.

Here is the finished gear. It is going to run with one I made about 2 years ago when I was learning how to do this.

All normal disclaimers apply