- Joined

- Aug 16, 2013

- Messages

- 1,033

- Reaction score

- 764

* * * WARNING! * * *

If you are looking for a fast paced, exciting thread that ends with a great model engine making that iconic first run . . . this isnt going to be it. This is going to be about trying to make the pattern and about as fast paced as watching paint dry. But it may have molten metal, sand, clay, smoke and fire!

Ive been messing around with casting for a few months now and for the last while Ive been concentrating on pattern making. I got inspired by fourstrokes (Dougies) Side Valve Engine build (http://www.homemodelenginemachinist.com/showthread.php?t=24250) and thought it was time to to try casting some engine parts. Reading Dougies thread (a few times) has provided me with answered to some of the problems I was having getting my head around the patterns and the cores.

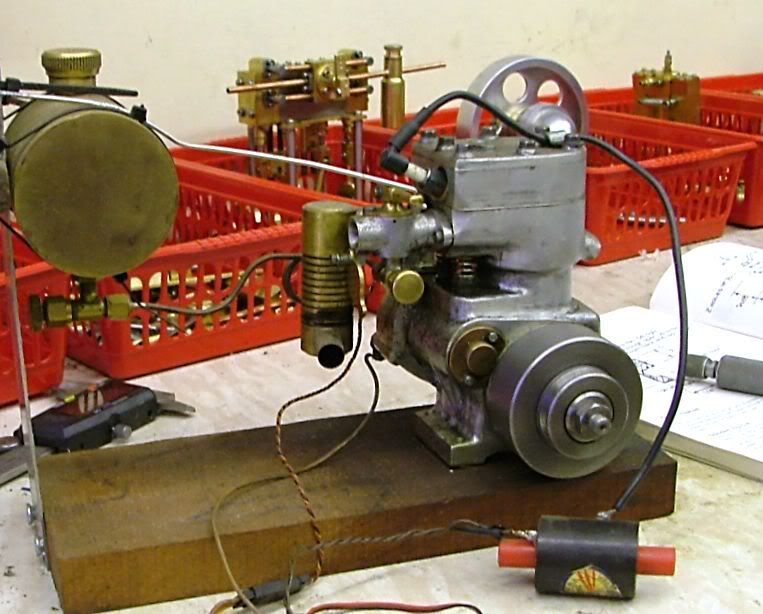

I started working on a set of patterns for the 10cc Whippet. Id seen copies of the plans on the internet and liked the engine but most seemed to be missing something. I guess this all started when I realised I had the original articles in Model Engineer No. 3221 to No. 3228. I have seen Whippets built from bar stock but these are inevitably people with CNC equipment and that is just never going to happen in my little shop without a Lottery win. This left either ordering the castings kit, £118.50 to £189.00 ($227.00 to $362.00 Can.) or making my own castings. Ive read more than one build article where they mention the castings where not great having soft or gummy spots. I thought I can probably make my own bad castings so homemade it is. The added benefit is that if/when I mess one up I can toss it back into the pot and just make a new one.

One of the first challenges I ran up against was that the drawings and construction notes assume you are working from there casting set so a lot of the external dimensions are not given. The only way I could think of to get around this was to model everything that had dimensions in CAD, so basically all the working parts.

If you are looking for a fast paced, exciting thread that ends with a great model engine making that iconic first run . . . this isnt going to be it. This is going to be about trying to make the pattern and about as fast paced as watching paint dry. But it may have molten metal, sand, clay, smoke and fire!

Ive been messing around with casting for a few months now and for the last while Ive been concentrating on pattern making. I got inspired by fourstrokes (Dougies) Side Valve Engine build (http://www.homemodelenginemachinist.com/showthread.php?t=24250) and thought it was time to to try casting some engine parts. Reading Dougies thread (a few times) has provided me with answered to some of the problems I was having getting my head around the patterns and the cores.

I started working on a set of patterns for the 10cc Whippet. Id seen copies of the plans on the internet and liked the engine but most seemed to be missing something. I guess this all started when I realised I had the original articles in Model Engineer No. 3221 to No. 3228. I have seen Whippets built from bar stock but these are inevitably people with CNC equipment and that is just never going to happen in my little shop without a Lottery win. This left either ordering the castings kit, £118.50 to £189.00 ($227.00 to $362.00 Can.) or making my own castings. Ive read more than one build article where they mention the castings where not great having soft or gummy spots. I thought I can probably make my own bad castings so homemade it is. The added benefit is that if/when I mess one up I can toss it back into the pot and just make a new one.

One of the first challenges I ran up against was that the drawings and construction notes assume you are working from there casting set so a lot of the external dimensions are not given. The only way I could think of to get around this was to model everything that had dimensions in CAD, so basically all the working parts.