rustyknife

Well-Known Member

- Joined

- Mar 5, 2011

- Messages

- 107

- Reaction score

- 1

I've been playing with metric thread pitches and checking them with a thread gauge...all spot on.

I must confess that I am rather an idiot....I had been putting off cutting SAE threads because mach 3 want you to enter the pitch in .000 of an inch. It took me about an hour of critical thinking and looking for charts on the internet before I realized that if you divide 1 inch by the threads per inch you get the number you need haha I never work with SAE fastners haha.

I never work with SAE fastners haha.

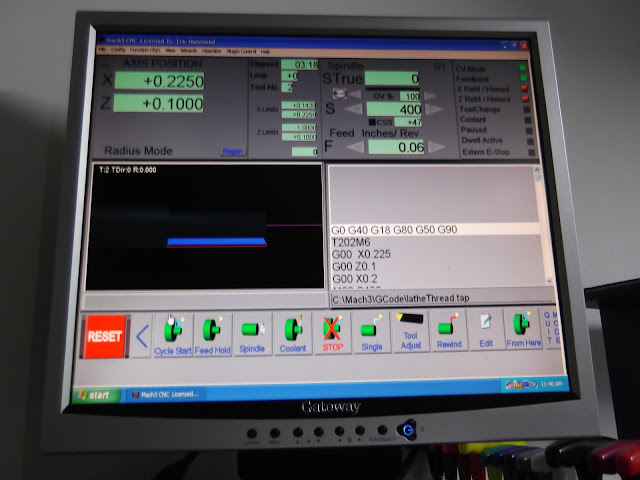

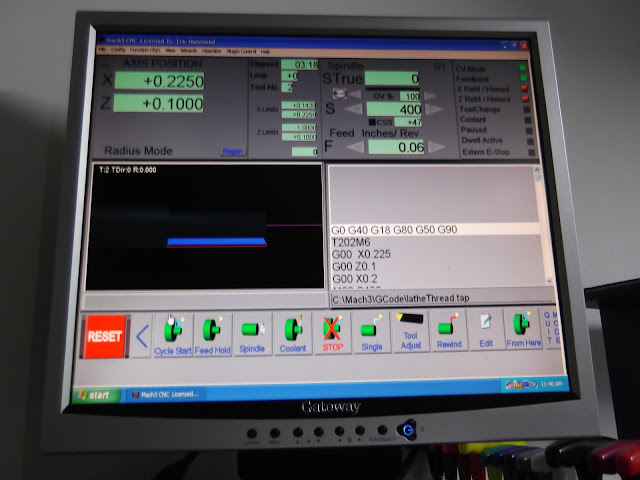

Anyways here's some pictures of me cutting 3/8 by 16 on a piece of 3/8 drill rod.

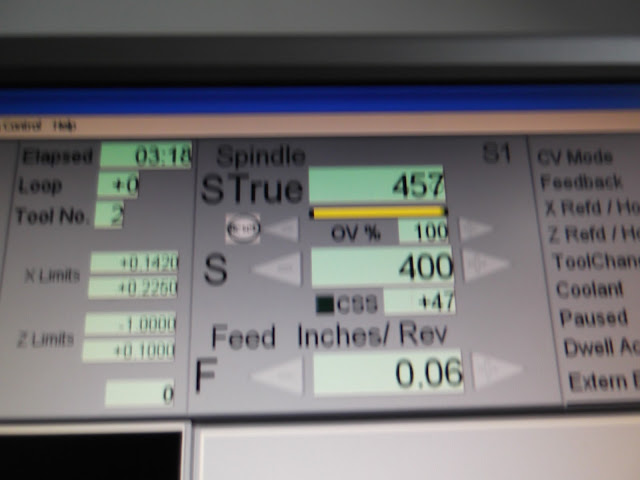

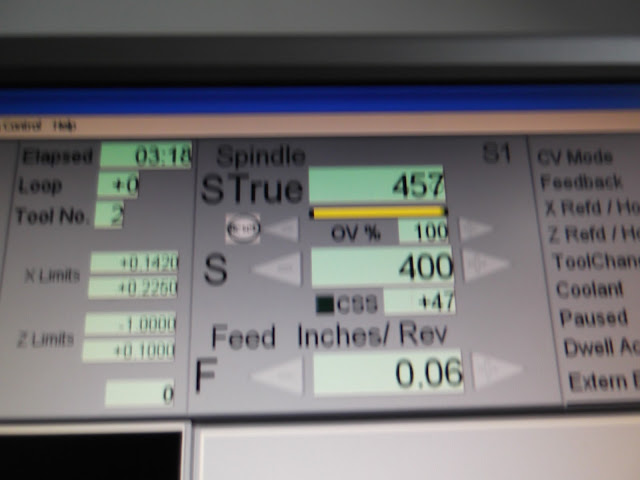

Spindle speed

I had a t-nut from my mill to check it with.

Success! ;D

I must confess that I am rather an idiot....I had been putting off cutting SAE threads because mach 3 want you to enter the pitch in .000 of an inch. It took me about an hour of critical thinking and looking for charts on the internet before I realized that if you divide 1 inch by the threads per inch you get the number you need haha

Anyways here's some pictures of me cutting 3/8 by 16 on a piece of 3/8 drill rod.

Spindle speed

I had a t-nut from my mill to check it with.

Success! ;D