Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

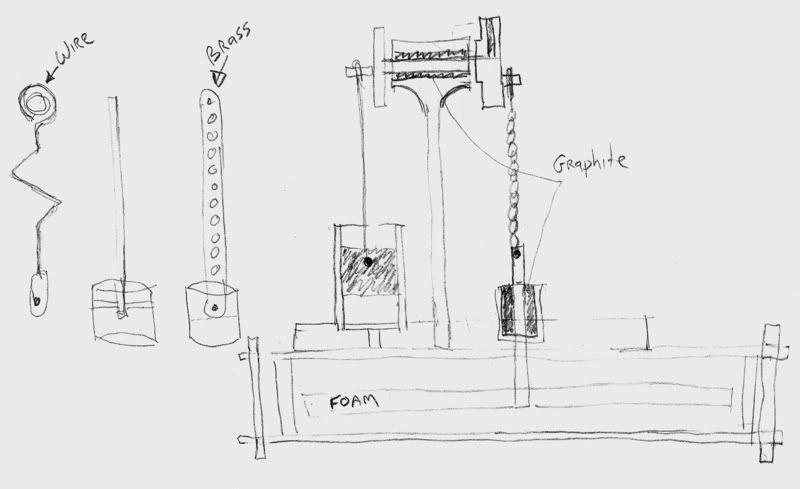

Powder keg said:So the top hat shaped aluminum piece fit in a hole in the foam? I imagine that there was a hole for the con rod to glue into? I'm thinking of gluing it and having a 2 piece con rod held together with some silicon tubing. If I can find some tubing small enough?

Maybe it would be better to have a more mechanical conection between the two conrod pieces that silicone tube?

Thanks for your input, Marv.

Wes

mklotz said:Wes,

Maybe I misunderstood you. An LTD Stirling is unlikely to have the power needed to flex a piece of tubing (if that was your intent). The connecting rod needs to have a very low friction connection. Exactly how you establish that is a design detail but it must be as low weight and friction as possible.

Enter your email address to join: