Twinsquirrel

Well-Known Member

- Joined

- Jun 8, 2008

- Messages

- 227

- Reaction score

- 0

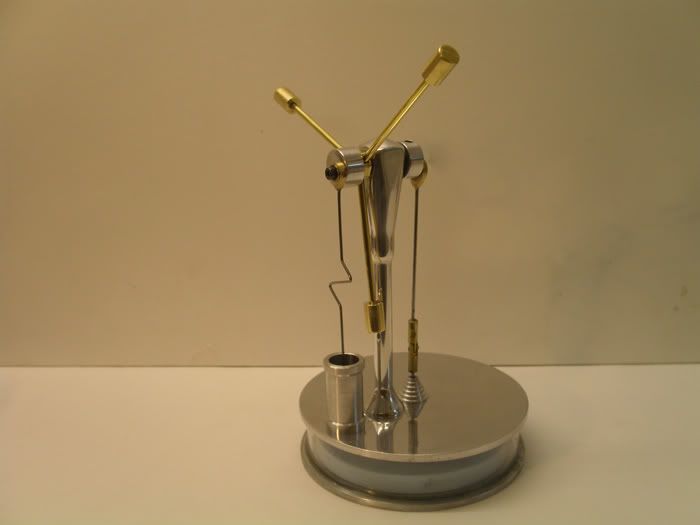

OK, this is the story so far on my first project on my lathe and my first proper engine, I'm not using plans just using the "ugly" LTD as a basis.

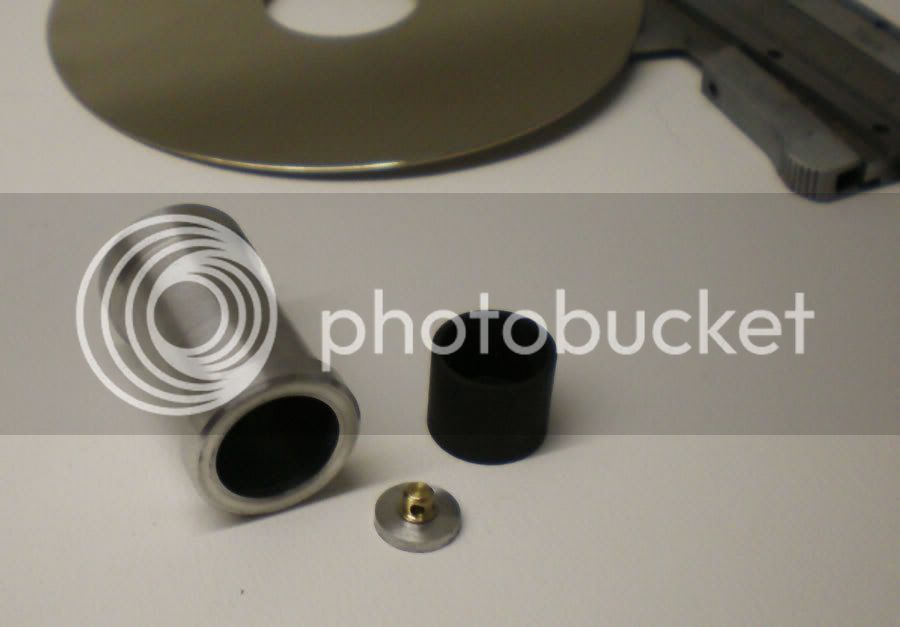

I have the top and bottom plates for the displacer cylinder done, I'm not that happy with the grooves or seats for the cylinder itself, not sure wether it was the tool I ground or the backlash in my cross-slide (now fixed) but I couldn't seem to make any cut without A LOT of chatter.

The displacer cylinder itself is cut from a spaghetti jar, it wasn't until I had marked out and cut the grooves in the top and bottom plates that I realised it had a slight taper....doh!!

Still I'm relatively pleased with the progress so far.

David

I have the top and bottom plates for the displacer cylinder done, I'm not that happy with the grooves or seats for the cylinder itself, not sure wether it was the tool I ground or the backlash in my cross-slide (now fixed) but I couldn't seem to make any cut without A LOT of chatter.

The displacer cylinder itself is cut from a spaghetti jar, it wasn't until I had marked out and cut the grooves in the top and bottom plates that I realised it had a slight taper....doh!!

Still I'm relatively pleased with the progress so far.

David