dozerdroid

New Member

Thank you for sharing, super cool.

Thanks Brian. Picked up a few ideas and methods over time here......some from your pages of know how!Lovely bit of work Longboy.................

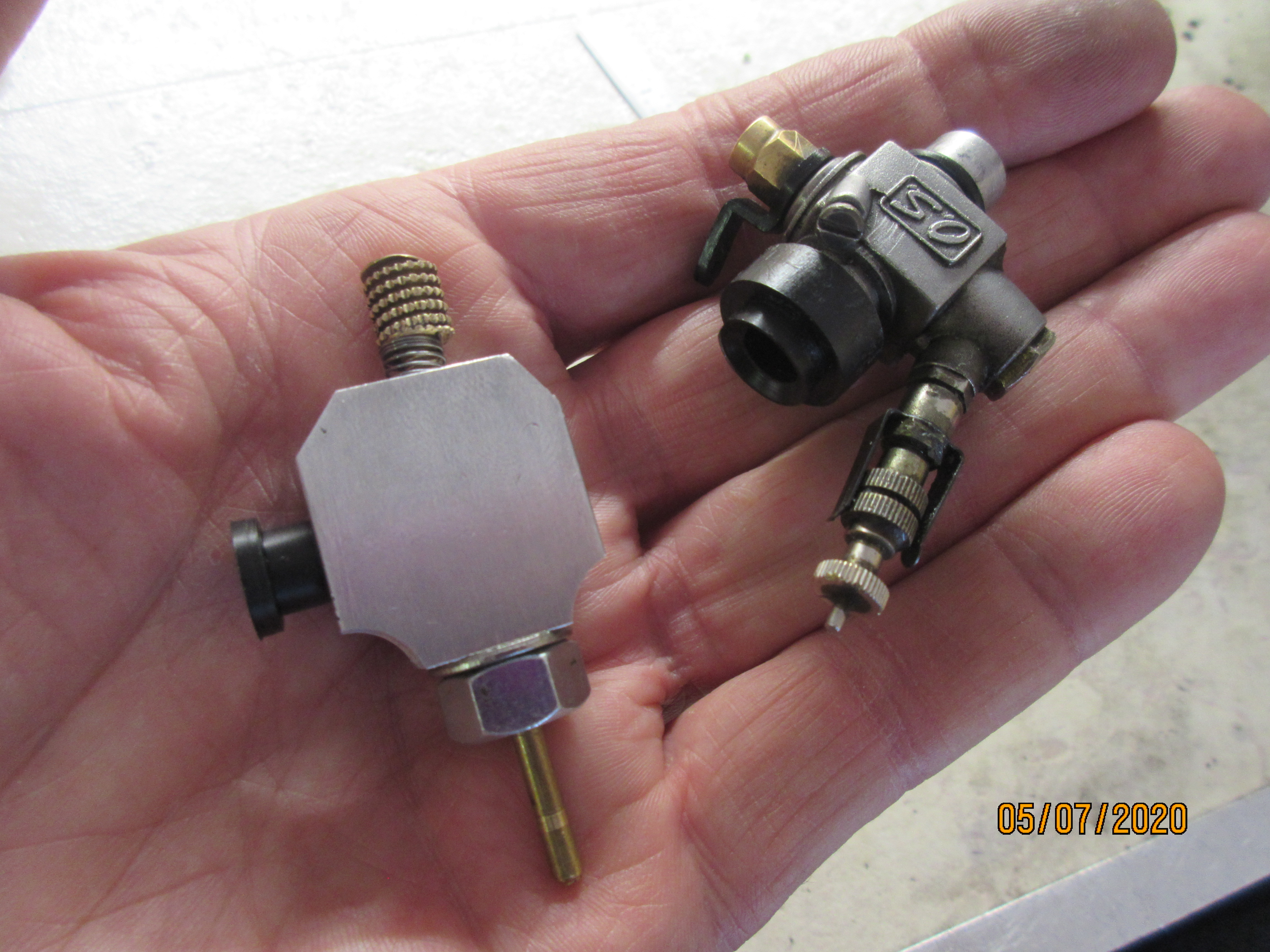

Yes. Fixed air jets and variable fuel.....no throttle.If I'm seeing right, it looks like you have only the needle adjustment, but no throttle - ?

Enter your email address to join: