You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Locomobile steam engine

- Thread starter mnay

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

sunworksco

Rocket Man

- Joined

- Nov 20, 2010

- Messages

- 243

- Reaction score

- 13

Will you be building the steam car, too?

sunworksco

Rocket Man

- Joined

- Nov 20, 2010

- Messages

- 243

- Reaction score

- 13

I have not decided. I have been working on this engine for so long, I may need a different project for a while to take a break.

I have even thought about putting it on a bicycle

Mike

I have a great drawing of an early steam motorbike if you would like to see it.

sunworksco

Rocket Man

- Joined

- Nov 20, 2010

- Messages

- 243

- Reaction score

- 13

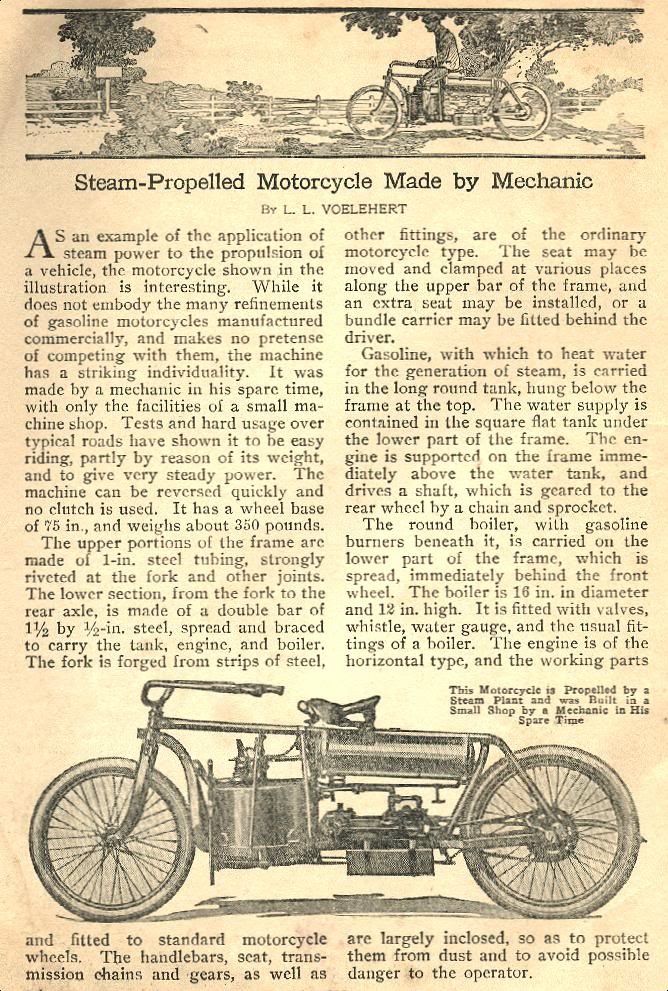

This is what I have. This would be a perfect steam motorbike platform for your Locomobile. There is a lot of length to lay the engine horizontally, like a Stanley engine. I would love to build the frame in aluminum and have it clear anodized. This would make a handsome contrast with the bronze metals.

sunworksco

Rocket Man

- Joined

- Nov 20, 2010

- Messages

- 243

- Reaction score

- 13

I think the frame is a very practical design for fitting all of the components. It would even work for an electric motorbike.

I, Thanks for this new possibility of applications, and generate sommes questions.

- what is the source and age of this bicycle article ?

- and it's possible to operate it with CO2 gaz?

and for mnay, i have search the article in steam review and unfotunately i have not find it.

Its be possible to have copie of this article of stanley steam car?

Thanks, Procule

- what is the source and age of this bicycle article ?

- and it's possible to operate it with CO2 gaz?

and for mnay, i have search the article in steam review and unfotunately i have not find it.

Its be possible to have copie of this article of stanley steam car?

Thanks, Procule

sunworksco

Rocket Man

- Joined

- Nov 20, 2010

- Messages

- 243

- Reaction score

- 13

This is from the 1919 Popular Mechanics book The Boy Mechanic, 800 things for boys to do. You can see the whole book here;

http://www.archive.org/stream/boymechanic03popu#page/n5/mode/2up

Go to page 191

http://www.steamcar.net/stanley/fastest.pdf

http://www.archive.org/stream/boymechanic03popu#page/n5/mode/2up

Go to page 191

http://www.steamcar.net/stanley/fastest.pdf

Not too much exciting to show, but I completed a couple of handfuls of parts.

I machined the valve end connections, the nuts to move the steam valves and the top brackets that hold the cross rods. I had to make the brackets as an addition because they normally would have been part of the castings but I am machining from bar stock and changing the design for my convenience in addition to scaling up from the plans

I machined the valve end connections, the nuts to move the steam valves and the top brackets that hold the cross rods. I had to make the brackets as an addition because they normally would have been part of the castings but I am machining from bar stock and changing the design for my convenience in addition to scaling up from the plans

After a few weeks of distractions and yard work, I have finally gotten back to my project.

After studying the plans and the engine I have discovered to my delight that I am close to finishing.

I was able to fabricate and machine the 2 lifting arms and the reversing lever.

After studying the plans and the engine I have discovered to my delight that I am close to finishing.

I was able to fabricate and machine the 2 lifting arms and the reversing lever.

I had previously build the pistons for this engine with the intent of making a carbon teflon rider ring in the center of the piston. I decided to go back to the original plan and machined a couple of pistons from cast iron. I will be making some cast iron rings next.

I made 4 cast iron rings to fit the pistons, using the wing-it method.

I machined the rings .050 over size, but with the correct radial thickness. I then machined a mandrel to fit the id of the rings after they were split and compressed, then turned the od to fit the cylinder bore.

they worked out perfectly and I got them all on without breaking one.

Lucky......

I machined the rings .050 over size, but with the correct radial thickness. I then machined a mandrel to fit the id of the rings after they were split and compressed, then turned the od to fit the cylinder bore.

they worked out perfectly and I got them all on without breaking one.

Lucky......

All of the parts have been machined. I was not patient enough to deburr and paint everything and wanted to test run so I deburred everything and assembled from the top down. I took me awhile to figure out how to time the valves, but it worked the first time I put air to it!!!!!!!Finally

[ame]http://youtu.be/Orpe3QFdWLQ[/ame]

[ame]http://youtu.be/Orpe3QFdWLQ[/ame]

Similar threads

- Replies

- 3

- Views

- 2K