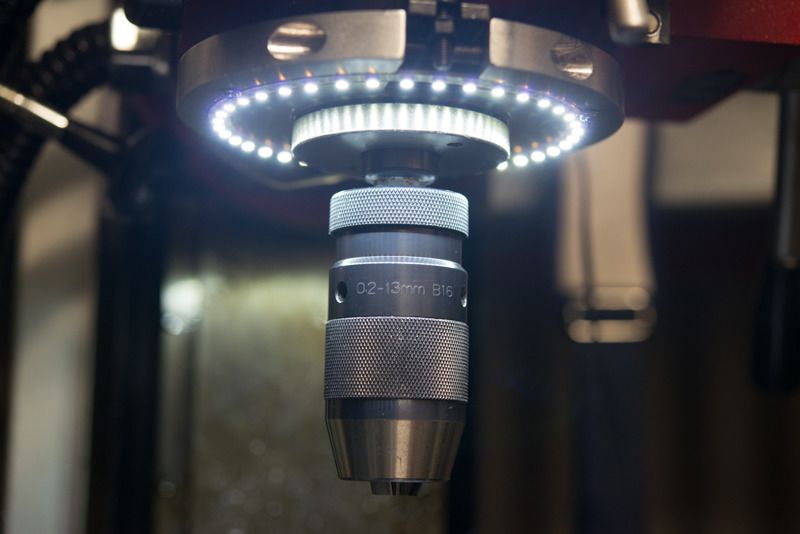

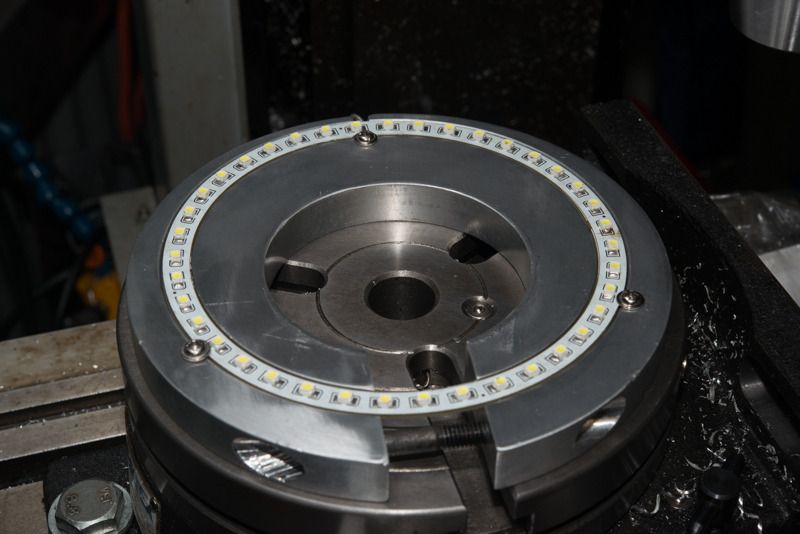

I'm considering putting an LED ring light round the quill on my milling machine.

Although others who have done the same say it gives a vastly improved light on the subject, I remember reading somewhere that especially when the quill is low down the work is in shadow from the chuck.

So, to the question: Would it be better to have a large diameter light ring say 100mm dia, or a smaller one that sits closely round the quill. (Quill is 60mm dia, so perhaps 70 mm dia light).

The alternative could be a strip of LEDs mounted on either side of the head.

Anyone with experience - good or bad - your thoughts are welcome.

Dave

The Emerald Isle

Although others who have done the same say it gives a vastly improved light on the subject, I remember reading somewhere that especially when the quill is low down the work is in shadow from the chuck.

So, to the question: Would it be better to have a large diameter light ring say 100mm dia, or a smaller one that sits closely round the quill. (Quill is 60mm dia, so perhaps 70 mm dia light).

The alternative could be a strip of LEDs mounted on either side of the head.

Anyone with experience - good or bad - your thoughts are welcome.

Dave

The Emerald Isle