More than a year ago I had to abandon a project because I couldn't cut a a tapered thread on my Logan lathe. I watched and bid on several taper attachments but they all sold for way may than I thought they were worth, considering all were incomplete or no model number available.

For a Logan lathe you need an extended cross slide with a slot in it as well as the guide bar. Not wanting to distort the cast iron cross slide I made a lap joint and silver brazed a steel extension to the cast iron. After milling the general shape I ground the bottom surface of the slotted area to be level with the top of the cross slide.

http://i272.photobucket.com/albums/jj165/sdmcw/TaperAttachment6.jpg[/img]]

The piece with the slot in my large radius thread was then ground to be parallel with the bottom of the cross slide.

http://i272.photobucket.com/albums/jj165/sdmcw/TaperAttachment5.jpg[/img]]

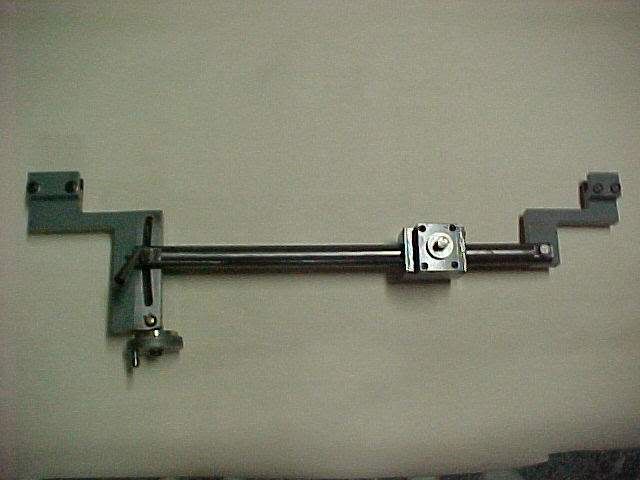

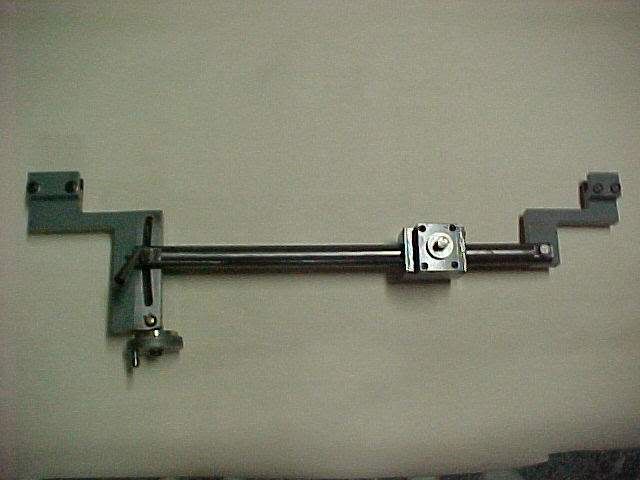

The guide bar is a piece of 4140 left over from another project and the traveler is a Thompson linear ball bearing in an aluminum housing with end plates that hold oil saturated felt wipers. Here are top and bottom vies of the completed assembly. In the bottom view you can see the holes in the traveler which are 8-32 set screws. These screws press on the backing plates behind the ball races. There are six rows of balls so I put adjusting screws on three with the opposite rows confined by the aluminum body.

http://i272.photobucket.com/albums/jj165/sdmcw/TaperAttachment9.jpg[/img]]

http://i272.photobucket.com/albums/jj165/sdmcw/TaperAttachment8.jpg[/img]]

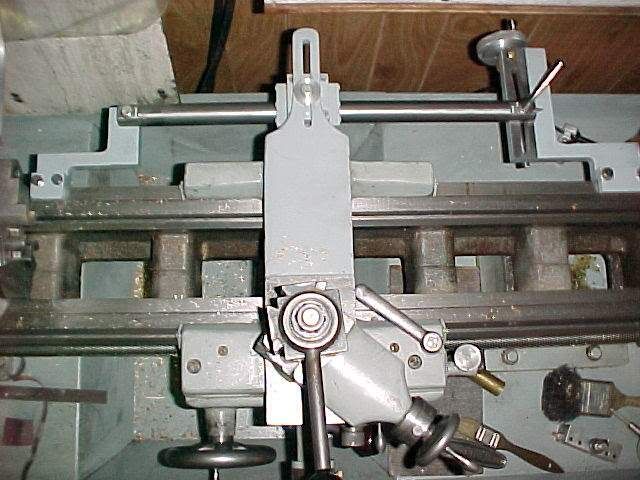

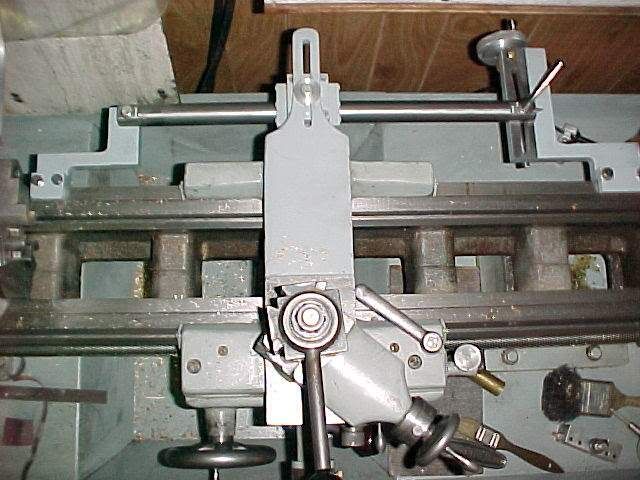

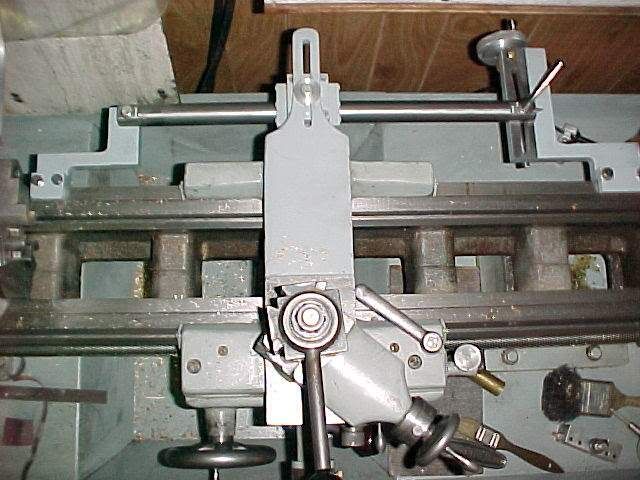

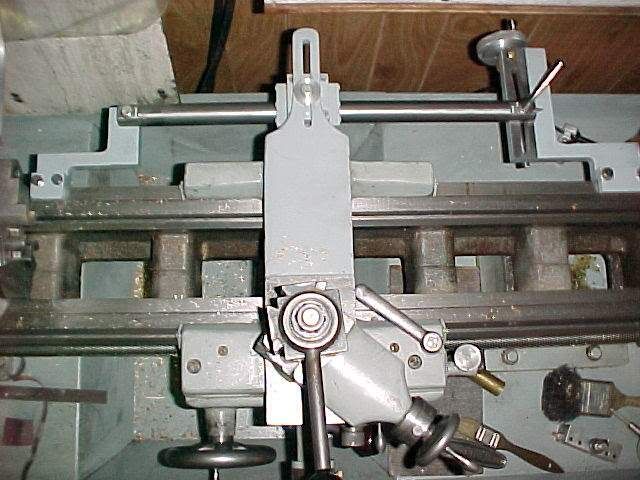

Here is the taper attachment mounted on the lathe.

][url]

][url]

[/url]

[/url]

As soon as it was installed I couldn't resist trying it out. I put a piece of 6061 in the chuck and cut a long 11 1/2 TPI on 3/4"/foot taper. I am not proud of the thread, I just wanted to see if it would work.

http://i272.photobucket.com/albums/jj165/sdmcw/TaperAttachment11.jpg[/img]]

For a Logan lathe you need an extended cross slide with a slot in it as well as the guide bar. Not wanting to distort the cast iron cross slide I made a lap joint and silver brazed a steel extension to the cast iron. After milling the general shape I ground the bottom surface of the slotted area to be level with the top of the cross slide.

http://i272.photobucket.com/albums/jj165/sdmcw/TaperAttachment6.jpg[/img]]

The piece with the slot in my large radius thread was then ground to be parallel with the bottom of the cross slide.

http://i272.photobucket.com/albums/jj165/sdmcw/TaperAttachment5.jpg[/img]]

The guide bar is a piece of 4140 left over from another project and the traveler is a Thompson linear ball bearing in an aluminum housing with end plates that hold oil saturated felt wipers. Here are top and bottom vies of the completed assembly. In the bottom view you can see the holes in the traveler which are 8-32 set screws. These screws press on the backing plates behind the ball races. There are six rows of balls so I put adjusting screws on three with the opposite rows confined by the aluminum body.

http://i272.photobucket.com/albums/jj165/sdmcw/TaperAttachment9.jpg[/img]]

http://i272.photobucket.com/albums/jj165/sdmcw/TaperAttachment8.jpg[/img]]

Here is the taper attachment mounted on the lathe.

][url]

][url]

[/url]

[/url]As soon as it was installed I couldn't resist trying it out. I put a piece of 6061 in the chuck and cut a long 11 1/2 TPI on 3/4"/foot taper. I am not proud of the thread, I just wanted to see if it would work.

http://i272.photobucket.com/albums/jj165/sdmcw/TaperAttachment11.jpg[/img]]