bananabearings

Member

- Joined

- Dec 2, 2012

- Messages

- 14

- Reaction score

- 3

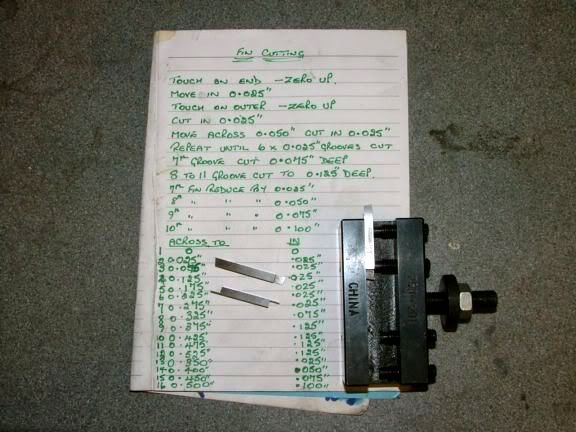

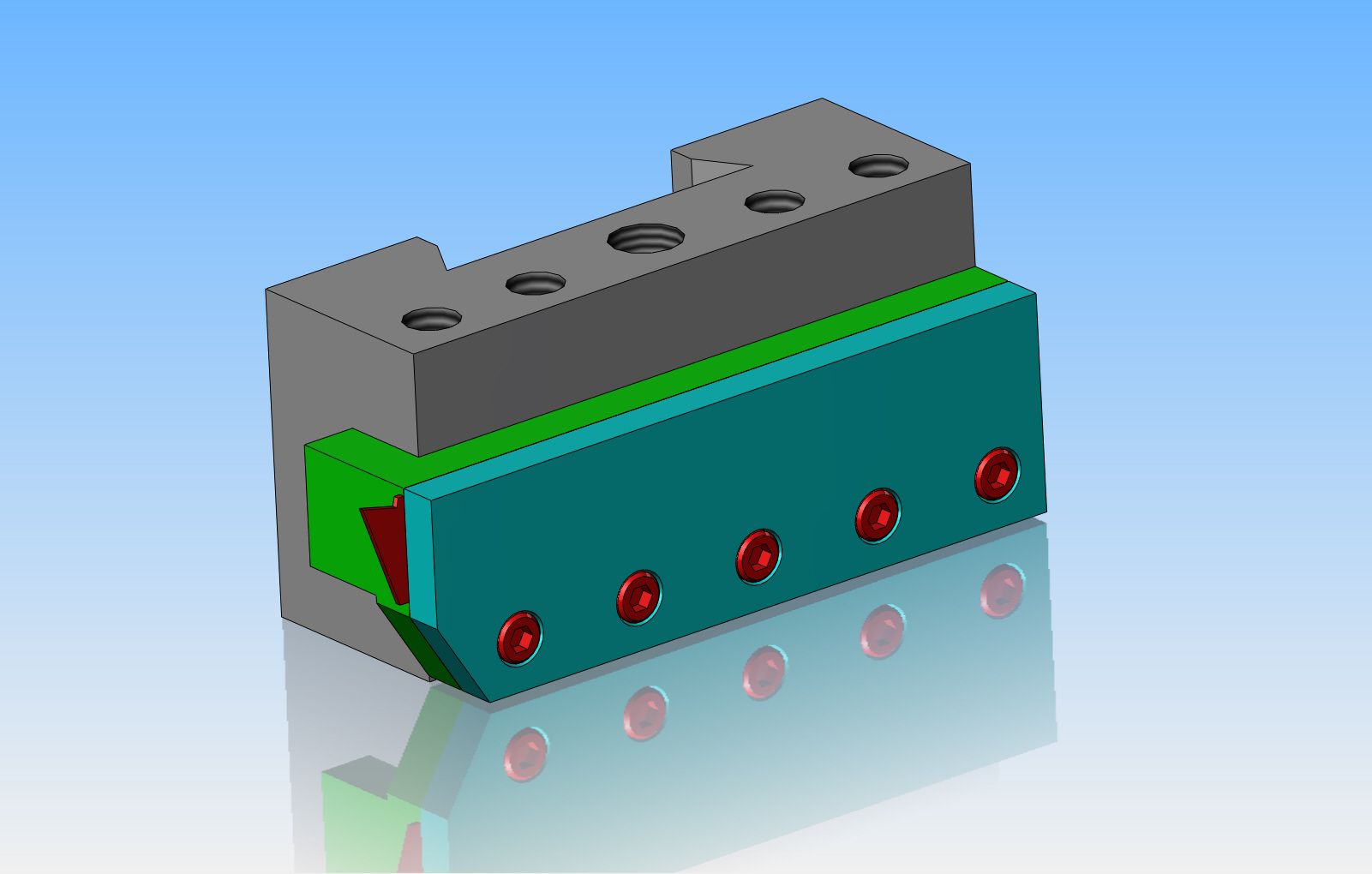

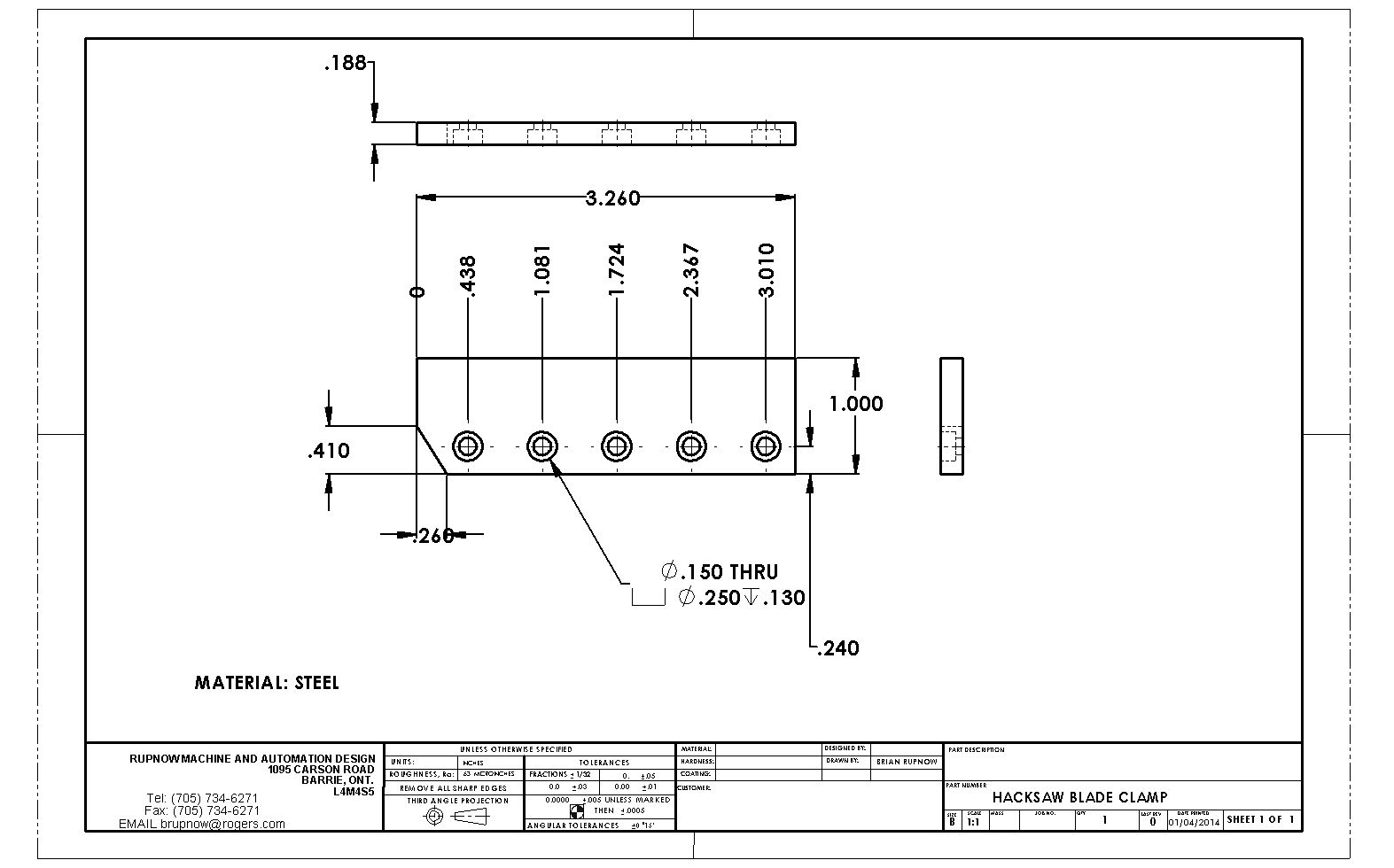

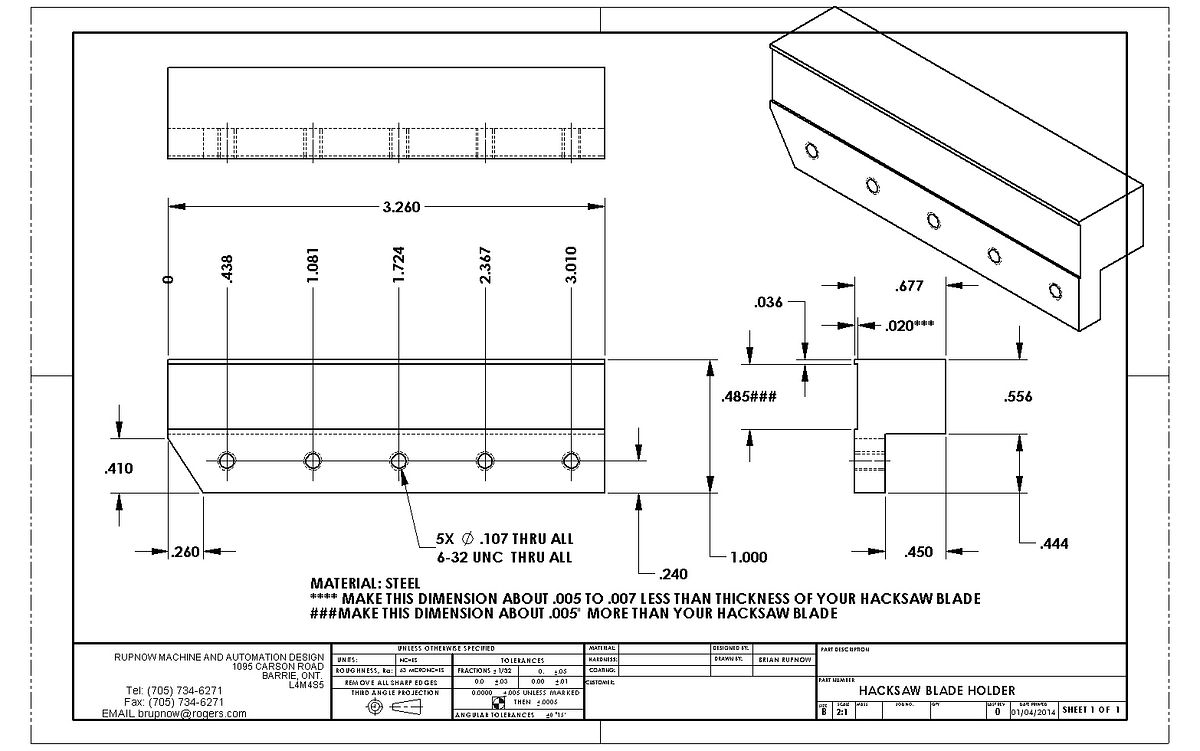

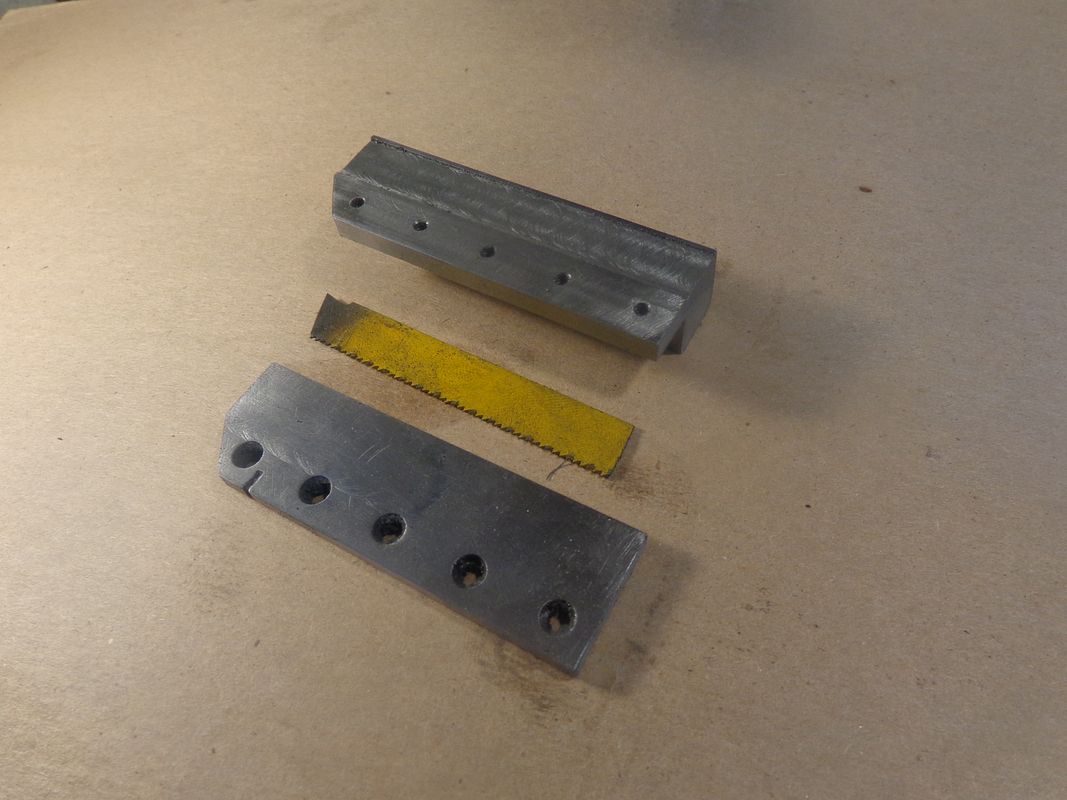

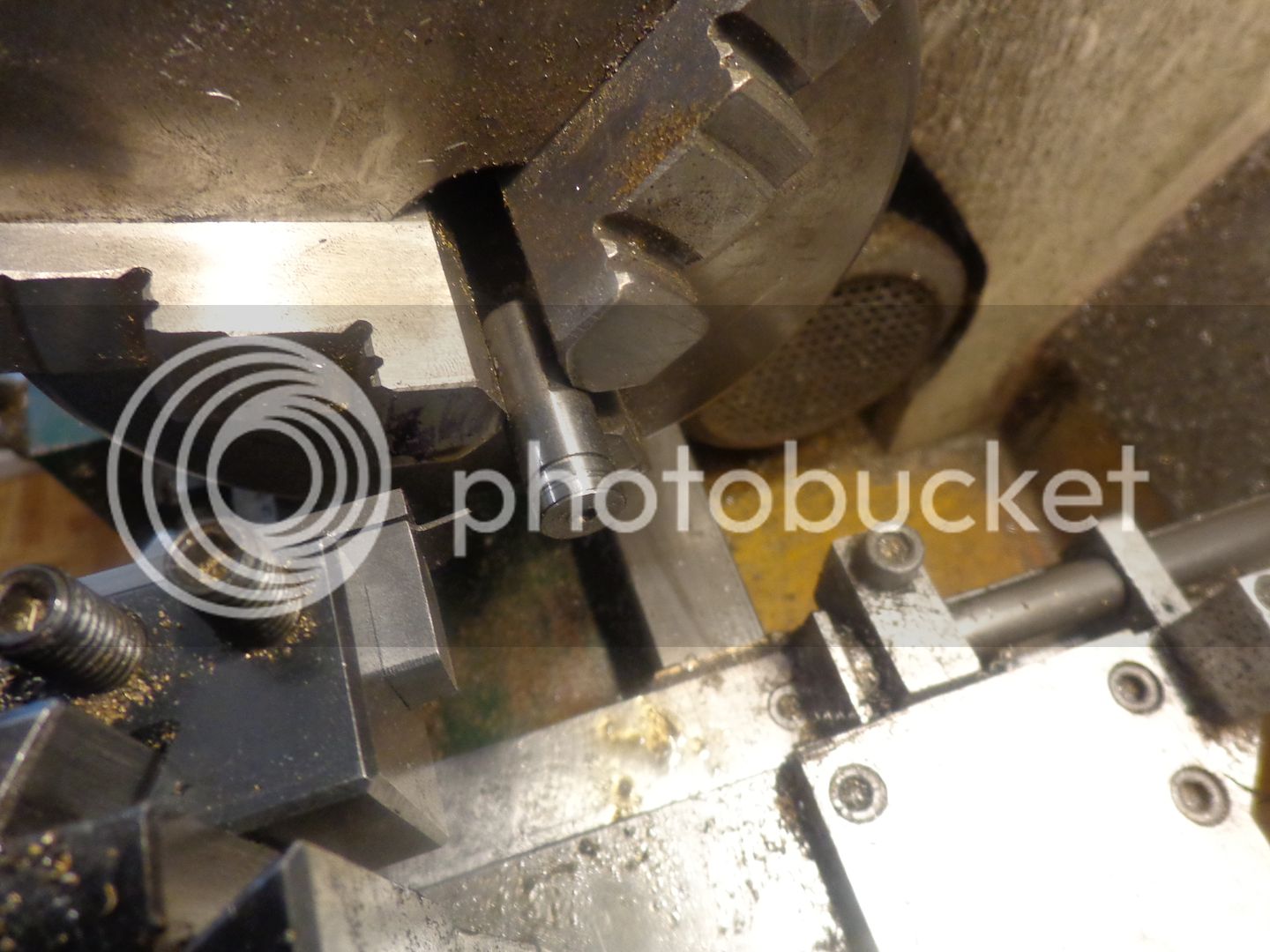

I spotted an image of the tool on Pinterest. Noticed it was from this forum. Sadly the other photos in the thread were no longer available. The original poster The Emerald Isle - Dave, kindly provided a few more photos.

So ..... my first build thread.

So ..... my first build thread.