This is going to be a new, short term project. Thursday my lathe broke down--something electrical. It is a heavy lathe, weighing about 400 pounds. I managed to move the lathe and the cabinets it is mounted on from my machine shop, thru my office, out into my main garage, where I unbolted the lathe from the cabinets and used my cherry picker engine hoist to lift it into the bed of my truck. I moved it using a tow rope, my truck, and a terrified wife who stood in the office and screamed STOP whenever the lathe was about to crash into anything---the tow rope went thru a few doorways and around a few corners. I don't know if any of you are familiar with the Darwin Award or not. I survived. Wife survived. Lathe survived. Sometime this week the lathe will be repaired and I will have to pick it up and repeat all of the above, only in reverse. I have just inventoried all of the scrap bits of angle bedframe, wheel casters, and heavy lumber in my various storage spots. I am going to build a heavy duty Dolly to mount the lathe on and roll the damned thing from my truck back into my machine shop. The Dolly will be about 1/4" higher than the cabinets that the lathe sets on so it can be slid from the dolly onto the cabinets---no lifting required. If I live as long as my mother, who is 100 years old, probably sooner or later I may have to move the lathe again.---Stay tuned!!!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathe Moving Dolly

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

There is a back story to this. Five or six years ago when I bought this lathe new, I brought it home from the store in my truck, off-loaded it, tried it out. It performed very well. I was a lot fatter and wimpier five or six years ago, so I hired "professional machinery movers" to move it from my main garage into my machine shop. Two huge men arrived, picked up the lathe, carried it into my machine shop.--and charged me $500. It took them all of 10 minutes to move the lathe. I'm a lot trimmer and in better overall health now, and I wasn't going to pay anybody to move the lathe. I don't want wheels on my lathe cabinets. the cabinets do not have leveling feet. It costs me nothing to make the dolly, and I will keep I around until I die or get sent to "the home".

- Joined

- Jan 17, 2009

- Messages

- 1,081

- Reaction score

- 278

I am sure there is a reason, but being "something electrical" why could not be fixed on situ.

I don't do electrical. I put in new fuse, check the wall outlet for power, and push the thermal safety overload reset on the motor if I can find it. If it's not one of those three, then I'm , euchred.

- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

Easier to move an electrician to the lathe rather than vice versa surely

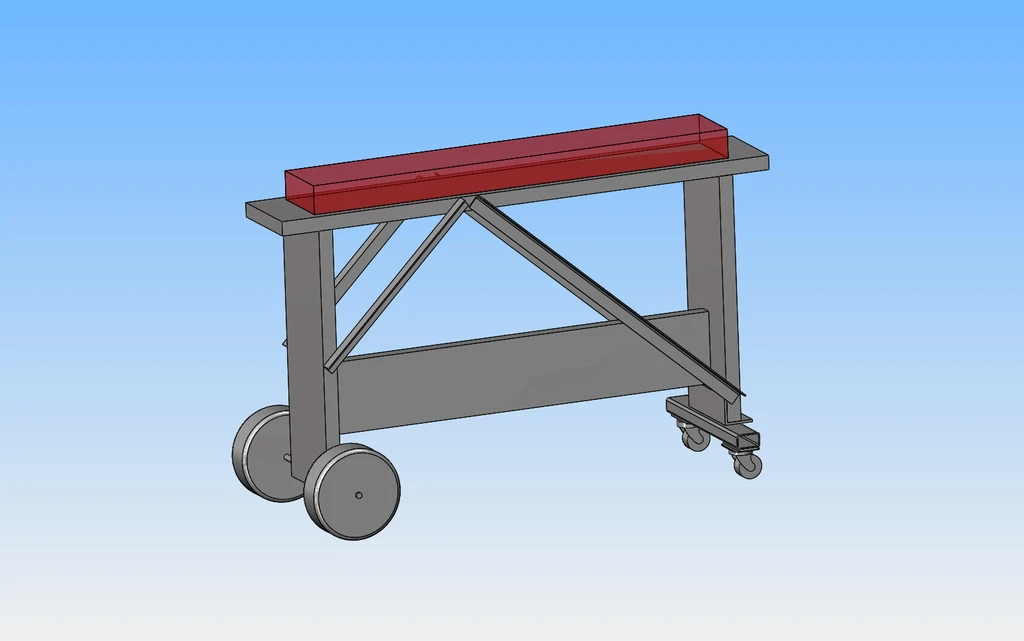

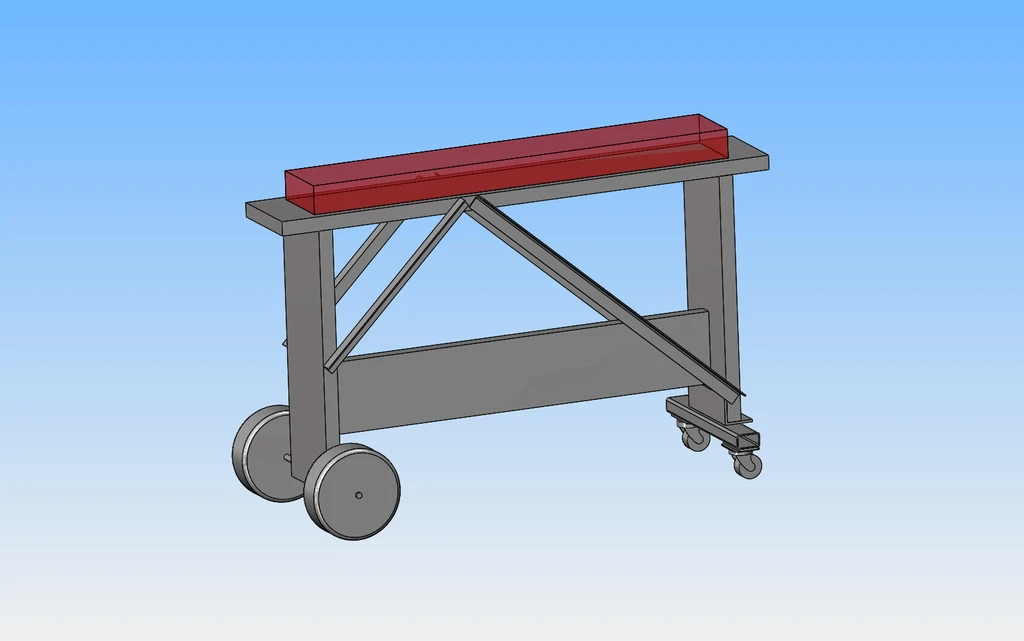

So--As I said, I will build a lathe transporting dolly with materials I have on hand. Small casters are from a moving crane I built about 25 years ago, then cut up and salvaged the material. Main body is 2" x 10" spruce, angles are old bedframe angles, and the two larger wheels and axle are off my handcart (borrowed) for the occasion. The red rectangle is the footprint of the lathe. The top of the dolly will be 3/4" higher than the cabinets that the lathe sets on. Lathe will be bolted to that top plank during transport. Steerable casters are 2 1/2" diameter. Larger wheels are 9 1/2" diameter pneumatic. Headstock end of lathe, which is by far the heaviest will set over these 9 1/2" wheels. I would have made the entire dolly much shorter and closer to the ground for stability, but my cherrypicker hoist will not fit into my machine shop. I have a secret weapon to help me with the move---a 180 pound son who works here in Barrie. After the move has been accomplished I will dismantle this dolly and band everything together and store it in case it is needed again some time. Thank you to everyone who responded to my post.----Brian

- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

As always you do the job properly,with lots of thought and not cutting corners

Brian, I feel your pain... We must move our home machine shop a distance of about 30 miles and I'm agonizing. I'm usually a DIY person but this will not be one of those. My largest lathe weighs a bit over 2300 lbs. One milling machine weighs about the same but for some reason I'm not as alarmed about moving it as I am the lathe. I have been putting this off for about three months now and am going through 'machine shop withdrawals' because my projects are on hold and I'm basically parallelized without my shop. This must be done by pros but unfortunately I'm also quite miserly too. Got to do it though - see no shortcuts. My steam locomotive is also just sitting in that same shop..about 1200lbs worth.

Bill

Bill

willray

Well-Known Member

Make dolly much, much wider, consider non-pneumatic tires: 400+ lbs on top of that, with pneumatic tires that will be squishy with a load, and you're just begging for a tip-over. This is not hypothetical.

Consider instead using your engine-hoist to lower it down to a floor-level dolly, roll it along nice and low, and raise it again at the end of the journey. Yes, I know your engine hoist won't fit in your shop. Raise it from your floor-level dolly back up to cabinet height by playing reverse-Jenga with thin wood blocks. 2x4 at the maximum, plywood preferably. You're almost certainly strong enough to lift one end of the lathe 3/4 inch at a time, while wife stuffs another block under. If you're not, 3/4 of an inch remains in the range of what can be done with a pry-bar.

If you absolutely must work with a cart as you've designed it, add solid outriggers that stick out wider than your wheels, and that just barely clear the ground with the cart loaded. That way if it starts to tip, the outrigger will stub into the floor and give you a bit of a safety margin.

Will Ray

Consider instead using your engine-hoist to lower it down to a floor-level dolly, roll it along nice and low, and raise it again at the end of the journey. Yes, I know your engine hoist won't fit in your shop. Raise it from your floor-level dolly back up to cabinet height by playing reverse-Jenga with thin wood blocks. 2x4 at the maximum, plywood preferably. You're almost certainly strong enough to lift one end of the lathe 3/4 inch at a time, while wife stuffs another block under. If you're not, 3/4 of an inch remains in the range of what can be done with a pry-bar.

If you absolutely must work with a cart as you've designed it, add solid outriggers that stick out wider than your wheels, and that just barely clear the ground with the cart loaded. That way if it starts to tip, the outrigger will stub into the floor and give you a bit of a safety margin.

Will Ray

Last edited:

willray

Well-Known Member

Brian, I feel your pain... We must move our home machine shop a distance of about 30 miles and I'm agonizing. I'm usually a DIY person but this will not be one of those. My largest lathe weighs a bit over 2300 lbs.

2300 lbs is entirely doable for DIY. Get yourself a pallet jack - you'll soon find it's your best friend. Jack the lathe up 6 inches, and lag it to a couple 6x6 timbers running cross-wise, say 1.5 feet wider than the lathe bed, more if you can afford the width. Pallet jack under the balance point and Bob's your uncle. If you've got to go the other way, 2 pallet jacks is still cheaper than riggers. Engine hoist will get you on and off a trailer, or, if it's a tilt-bed, a couple 2x runners, some grease and a come-along.

In my opinion, the mill is scarier (it's harder to build a stable footprint under it), unless you go the sane route and pull the overarm for transport.

Will Ray

Pallet jack under the balance point and Bob's your uncle.

Will Ray

Appreciate the advice as I'm sure Brian does too. Your ideas are good but there is another factor that is dominate in my case. I'm recovering from knee replacement surgery - both knees - and I'm not so steady on them yet. Time flies, the wind blew and I'm not going to risk my equipment just to accomplish a DIY.

Bill

NIGHTMARE!!Brian Rupnow and billC

I hate to hear about lathes face planting and braking all the hand wheels, its traumatizing so be careful with your move its also dangerous..

willray

Well-Known Member

Appreciate the advice as I'm sure Brian does too. Your ideas are good but there is another factor that is dominate in my case. I'm recovering from knee replacement surgery - both knees - and I'm not so steady on them yet. Time flies, the wind blew and I'm not going to risk my equipment just to accomplish a DIY.

If you have physical limitations that cause you to be one of the significant random variables in the process, then you gotta do what you gotta do to protect you. With a bit of care, you can make the risk to the equipment pretty much nil, but breaking you is not an option.

I will say, the more you do it, the easier it seems. The first time I moved a 1200lb mill (a little-bitty Nichols), I was pretty much terrified of the process. I'm stilly mighty respectful of the fact that even a 1200lb machine can squash me plenty flat. But having moved considerably heavier stuff around quite a bit since, I now know and trust my rigging and equipment a lot better, and it's easier to see what things I really need to worry about, and what things are just distractions.

You can make your lathe essentially tip-proof, if you choose. Whether you can make the process of moving it you proof however is a decision only you can make.

Best of luck with your move - if you were closer to the Ohio side of Virginia, I'd come over and move stuff for you. After a fashion, rigging stuff gets kind of fun.

Will Ray

Last edited:

willray

Well-Known Member

... lag it to a couple 6x6 timbers running cross-wise, say 1.5 feet wider than the lathe bed...

Correction - I meant to say 1.5 feet wider on both sides, than the lathe base...

Richard Hed

Well-Known Member

- Joined

- Nov 23, 2018

- Messages

- 2,380

- Reaction score

- 615

I thimk you may needs to seeks counselling.Brian, I feel your pain... We must move our home machine shop a distance of about 30 miles and I'm agonizing. I'm usually a DIY person but this will not be one of those. My largest lathe weighs a bit over 2300 lbs. One milling machine weighs about the same but for some reason I'm not as alarmed about moving it as I am the lathe. I have been putting this off for about three months now and am going through 'machine shop withdrawals' because my projects are on hold and I'm basically parallelized without my shop. This must be done by pros but unfortunately I'm also quite miserly too. Got to do it though - see no shortcuts. My steam locomotive is also just sitting in that same shop..about 1200lbs worth.

Bill

Richard Hed

Well-Known Member

- Joined

- Nov 23, 2018

- Messages

- 2,380

- Reaction score

- 615

Moving a mill is not too difficult: get some ordinary iron pipe, about 3/4 or 1", 3 pieces, and put two at a time under the foot. roll the mill and use the 3rd piece to place under the foot as it needs. I have done this several times. However, getting the mill UP onto a truck or what ever is a different problem. I used an incline plane and a come along.2300 lbs is entirely doable for DIY. Get yourself a pallet jack - you'll soon find it's your best friend. Jack the lathe up 6 inches, and lag it to a couple 6x6 timbers running cross-wise, say 1.5 feet wider than the lathe bed, more if you can afford the width. Pallet jack under the balance point and Bob's your uncle. If you've got to go the other way, 2 pallet jacks is still cheaper than riggers. Engine hoist will get you on and off a trailer, or, if it's a tilt-bed, a couple 2x runners, some grease and a come-along.

In my opinion, the mill is scarier (it's harder to build a stable footprint under it), unless you go the sane route and pull the overarm for transport.

Will Ray

Richard Hed

Well-Known Member

- Joined

- Nov 23, 2018

- Messages

- 2,380

- Reaction score

- 615

Well, if you lived in a reasonalbe place, Like the Soviet of Washington, I could help you, but as you live clear across the country, forget it. HOw about the space concerns in your new place?NIGHTMARE!!

My first lathe was a 11" Sheldon, they loaded it. When I got home, I'm looking at this and thinking how I'm I going to get it off.

Well, I got the fire wood blocking, stacked the wood the height of the bed of the truck.

Got 2 planks and put them under the lathe and slid it back 1/2" by 1/2" till the plank and lathe was on the wood.

Then took the wood out piece by piece, till it was on the driveway. Then put pipe under it and rolled in the basement.

I thought there has to be another way. I got 3 long pipe to make a tripod, then used a come-along. A pickup would fit under, much later I got a used pallet jack to move the equipment. I have just about everything on 4x4's so I can move it. The Excello mill, about 3000lb. was the heaviest.

Well, I got the fire wood blocking, stacked the wood the height of the bed of the truck.

Got 2 planks and put them under the lathe and slid it back 1/2" by 1/2" till the plank and lathe was on the wood.

Then took the wood out piece by piece, till it was on the driveway. Then put pipe under it and rolled in the basement.

I thought there has to be another way. I got 3 long pipe to make a tripod, then used a come-along. A pickup would fit under, much later I got a used pallet jack to move the equipment. I have just about everything on 4x4's so I can move it. The Excello mill, about 3000lb. was the heaviest.

Similar threads

- Replies

- 38

- Views

- 11K