Busted Bricks

Member

Hi All

I'm really just thinking out loud here but it would be nice to get some feedback

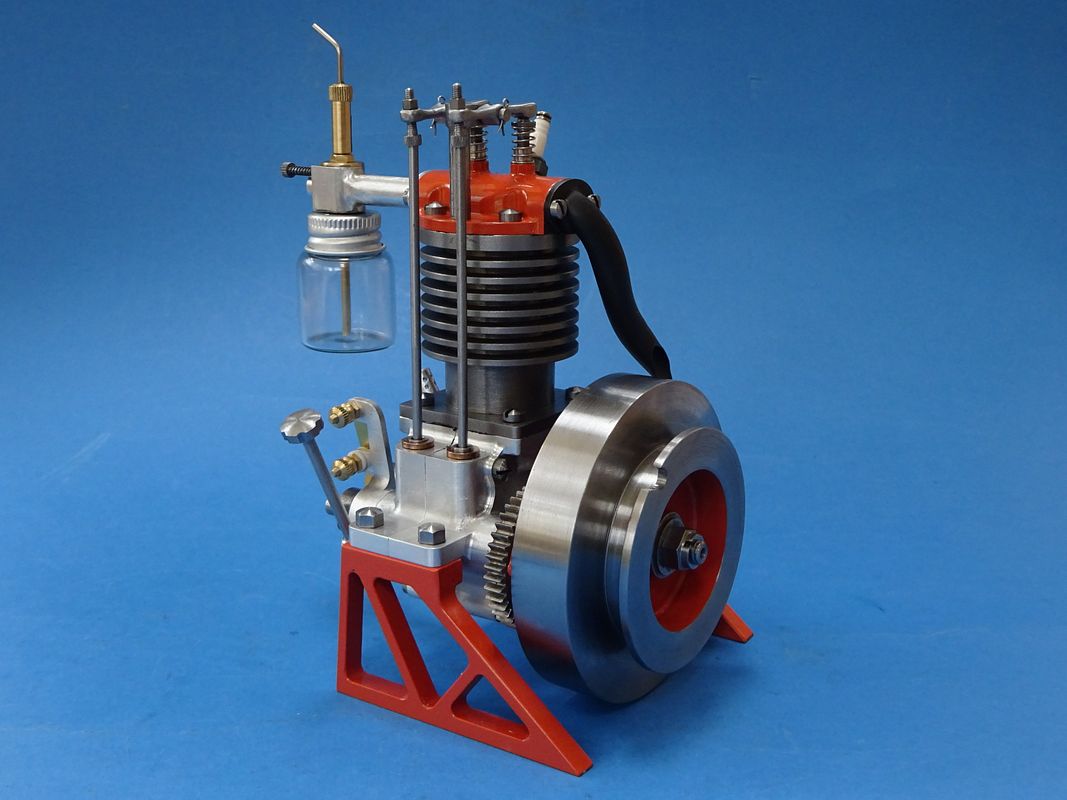

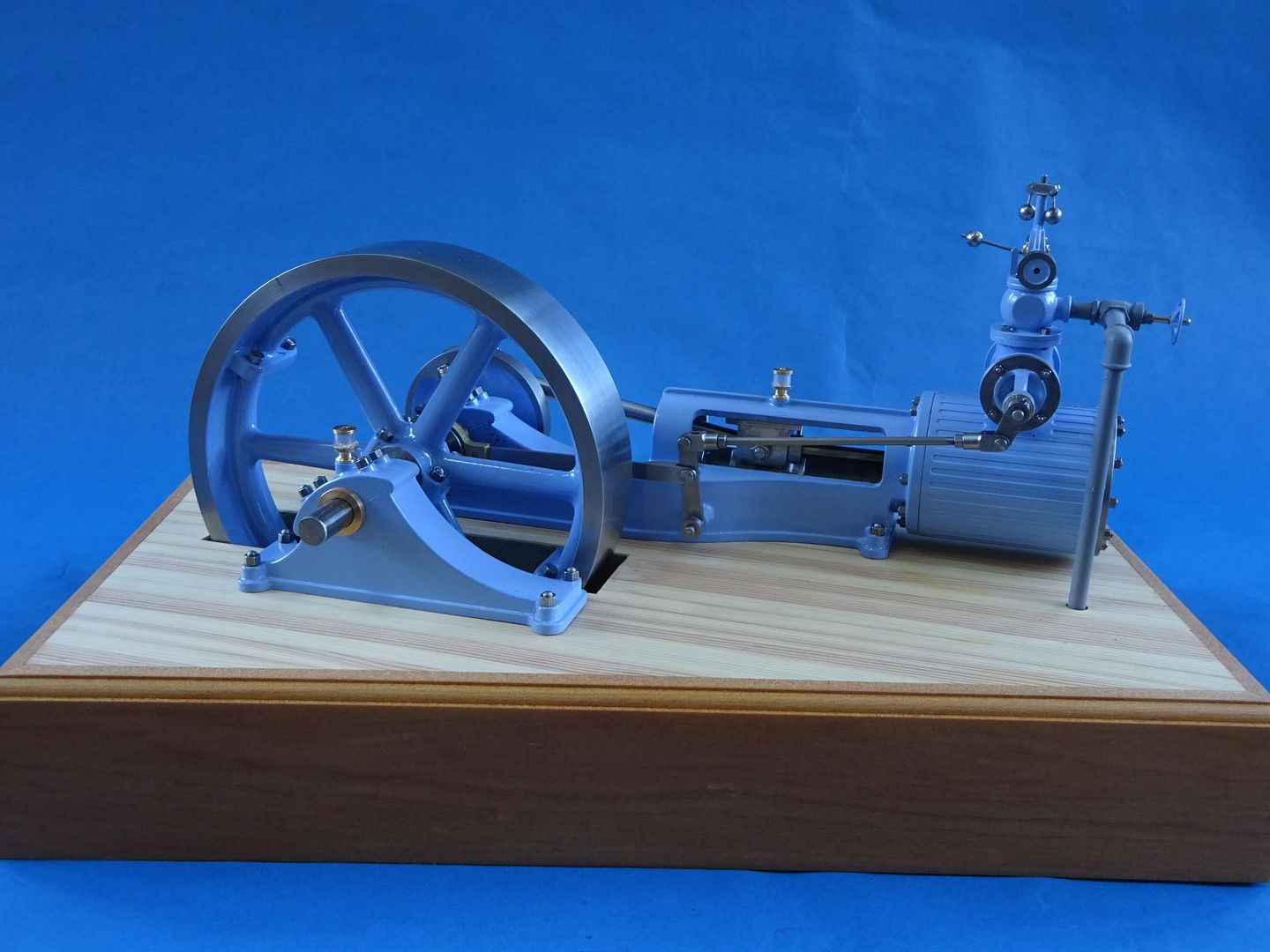

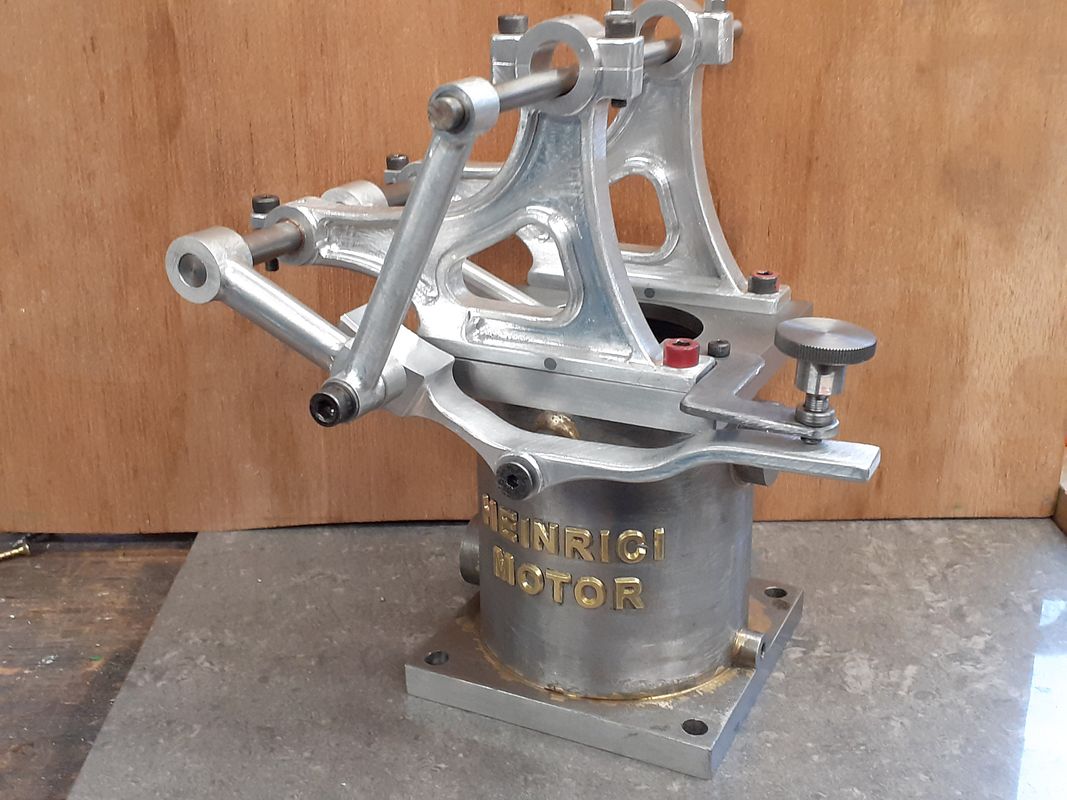

I run a laser cutting business and can cut up to 10mm mild steel. I have also recently bought a Mazak QT6 CNC lathe and a Syil X7-20 VMC has been ordered and should arrive in a few months time. I have been following the PM Research build series by Blondihacks and Joe Pie on Youtube. Those engines are machined from castings. It got me thinking that many of the cast parts could be laser cut instead. They would of course look different and parts like the frame would need to be built up from multiple parts that are bolted or soldered together. I imagine the finished look would be somewhat "agricultural" Whilst tolerances on laser cut parts are pretty good, some surfaces would still need to be machined and holes would need to be reamed. Other parts could be made from bar stock, perhaps with some rough machining done on the lathe/VMC.

Would anyone be interested in building an engine like this from a kit of parts? Would anyone be interested in working on the design with me? I always have a lot of scrap sheet material from customer jobs so making small prototype parts for a steam engine would not break the bank for me.

I'm really just thinking out loud here but it would be nice to get some feedback

I run a laser cutting business and can cut up to 10mm mild steel. I have also recently bought a Mazak QT6 CNC lathe and a Syil X7-20 VMC has been ordered and should arrive in a few months time. I have been following the PM Research build series by Blondihacks and Joe Pie on Youtube. Those engines are machined from castings. It got me thinking that many of the cast parts could be laser cut instead. They would of course look different and parts like the frame would need to be built up from multiple parts that are bolted or soldered together. I imagine the finished look would be somewhat "agricultural" Whilst tolerances on laser cut parts are pretty good, some surfaces would still need to be machined and holes would need to be reamed. Other parts could be made from bar stock, perhaps with some rough machining done on the lathe/VMC.

Would anyone be interested in building an engine like this from a kit of parts? Would anyone be interested in working on the design with me? I always have a lot of scrap sheet material from customer jobs so making small prototype parts for a steam engine would not break the bank for me.