jimsshop1

Steamman70

- Joined

- Nov 23, 2016

- Messages

- 117

- Reaction score

- 27

Hi all,

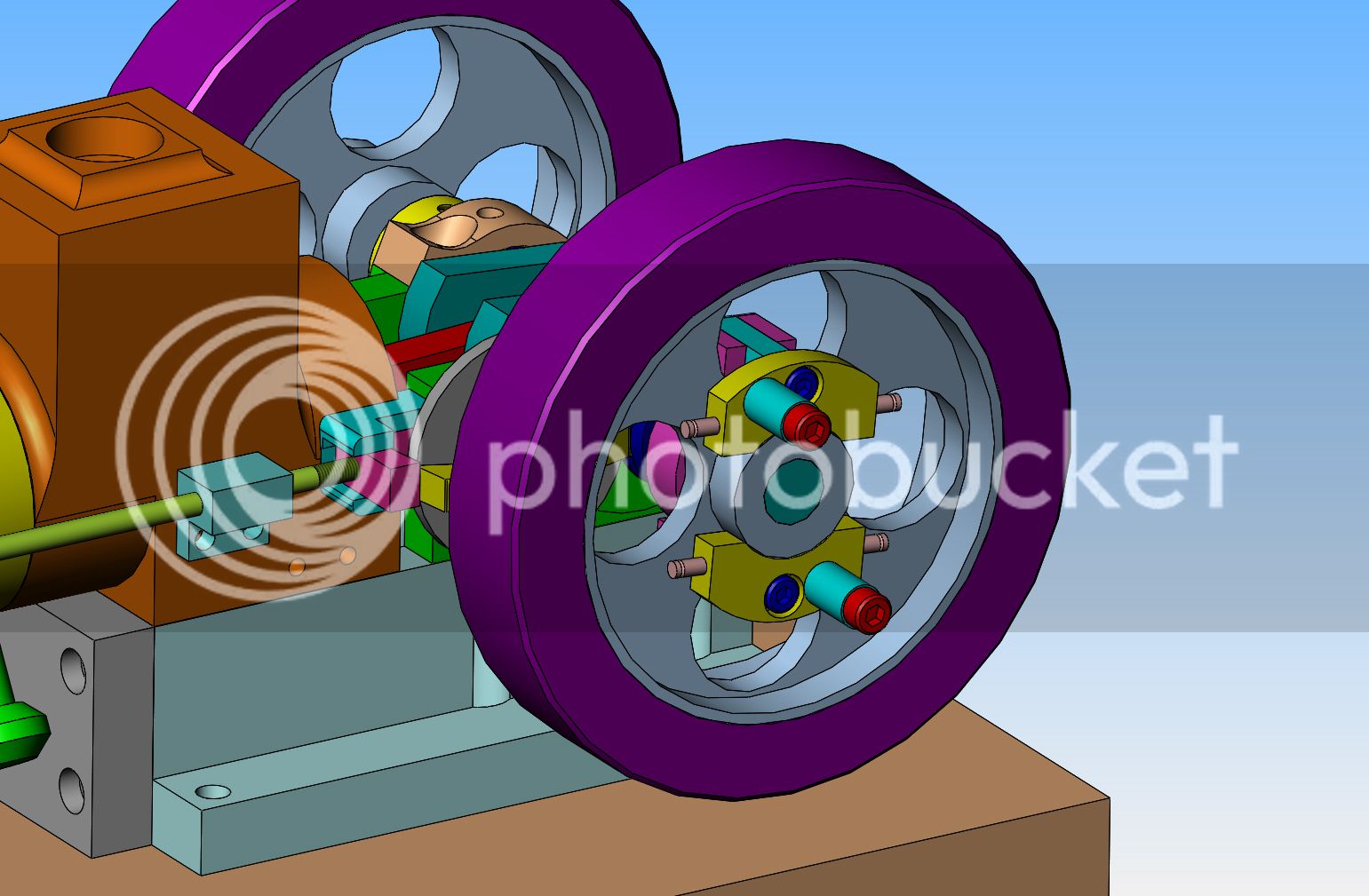

I started the Kerzel almost 2 years ago. After machining all the parts and assembling it all, I tried for months to get it running. It would fire with a drill running it but as soon as the drill was removed it would stall. I even wore out one of the crank bushings from trying everything I knew to get it to run on it's own. Finally I put it away and moved on to rebuilding a couple of full size hit miss engines. In doing these restorations I realized that the flywheels were massive and heavy on both of them. This got me to thinking about the Kerzel. Maybe the flywheels were not heavy enough to keep the engine running so I turned a couple of Brass Rings and heated them up a bit and dropped them over the original flywheels. Then I trued them up in my trusty South Bend 9" and put them back on the Kerzel. Guess what? The thing ran like a top! Problem solved. I now have a beautiful running engine and would like to post a video of it running for you guys to see. I have uploaded the video to youtube but can't figure out how to post it on here. If someone could help me do this I will show it on here today.

BTW I have been on here for a couple years under a different name as 65arboc but for some reason I lost my account and had to re register as a new user. Thanks for all I have learned from this forum. What a great bunch of people on here!::thumbup:

Jim in Pa

I started the Kerzel almost 2 years ago. After machining all the parts and assembling it all, I tried for months to get it running. It would fire with a drill running it but as soon as the drill was removed it would stall. I even wore out one of the crank bushings from trying everything I knew to get it to run on it's own. Finally I put it away and moved on to rebuilding a couple of full size hit miss engines. In doing these restorations I realized that the flywheels were massive and heavy on both of them. This got me to thinking about the Kerzel. Maybe the flywheels were not heavy enough to keep the engine running so I turned a couple of Brass Rings and heated them up a bit and dropped them over the original flywheels. Then I trued them up in my trusty South Bend 9" and put them back on the Kerzel. Guess what? The thing ran like a top! Problem solved. I now have a beautiful running engine and would like to post a video of it running for you guys to see. I have uploaded the video to youtube but can't figure out how to post it on here. If someone could help me do this I will show it on here today.

BTW I have been on here for a couple years under a different name as 65arboc but for some reason I lost my account and had to re register as a new user. Thanks for all I have learned from this forum. What a great bunch of people on here!::thumbup:

Jim in Pa