- Joined

- Jun 4, 2008

- Messages

- 3,285

- Reaction score

- 630

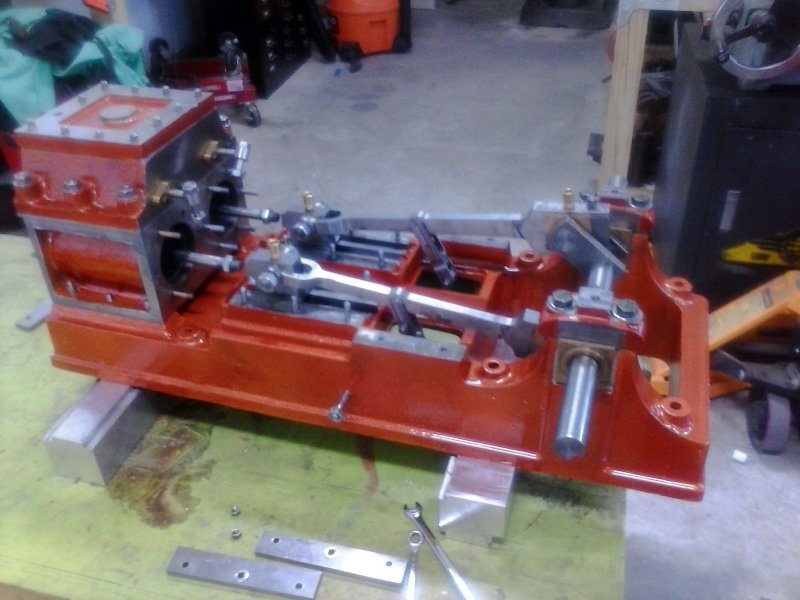

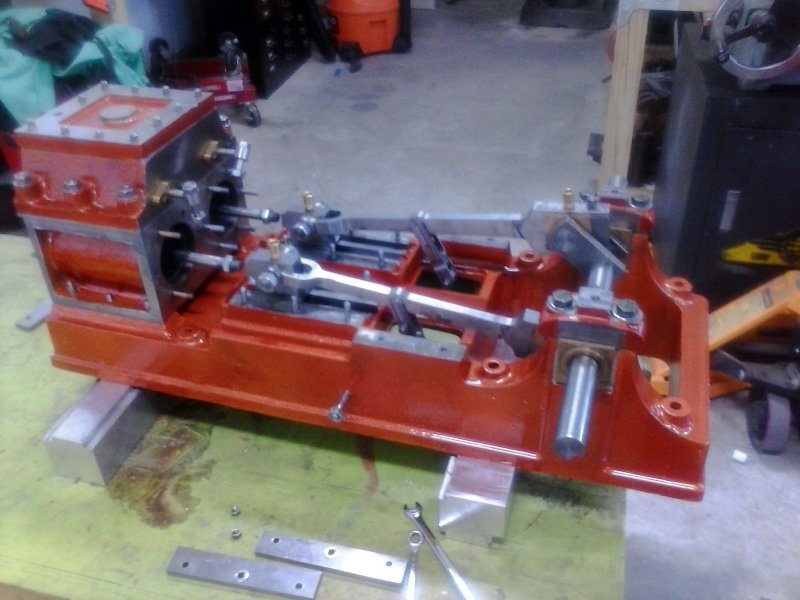

Painted the base yesterday, and started reassembly this afternoon. The paint job turned out OK in the end; not professional but decent from a couple of feet away. The paint is fairly thin and tended to run a bit down vertical surfaces so being slightly darker on crevices where it pooled. Here's where I stopped mid-afternoon.

I need to shim the cylinder and crosshead bars in order to get the crank and piston moving smoothly before putting the valve gear and reversing mechanism in place.

I need to shim the cylinder and crosshead bars in order to get the crank and piston moving smoothly before putting the valve gear and reversing mechanism in place.