rodw

Well-Known Member

- Joined

- Dec 2, 2012

- Messages

- 1,146

- Reaction score

- 340

You can read the thread where this is documented form go to woe during the development here:

http://www.homemodelenginemachinist.com/showthread.php?p=273830#post273830

if you need more help but this thread is designed to provide a simple easy to install solution of version 10 of my Rotary Table controller.

I am going to assume you already have installed the Arduino IDE on your PC. Don't worry if you don't have an Arduino at this stage.

All you have to do is to find the Arduino folder in "My Documents". On my PC it was in this folder C:\Users\Rod\Documents\Arduino and unzip the attached file into it. I am guessing that you have a different name to me so it will be a bit different on your PC Please substitute my name with yours....

Please substitute my name with yours....

So you should now have the following folders in the Arduino folder

C:\Users\Rod\Documents\Arduino\libraries

C:\Users\Rod\Documents\Arduino\RotaryTable10

In the Libraries folder you should find the following folders

C:\Users\Rod\Documents\Arduino\libraries\LCD

C:\Users\Rod\Documents\Arduino\libraries\TimerOne-r11

In the C:\Users\Rod\Documents\Arduino\RotaryTable10 folder you will find the following files:

EEPROMAnything.h

RotaryTable10.ino

Assuming you have the Arduino IDE installed on your PC if you double click on

RotaryTable10.ino and it should open in the IDE.

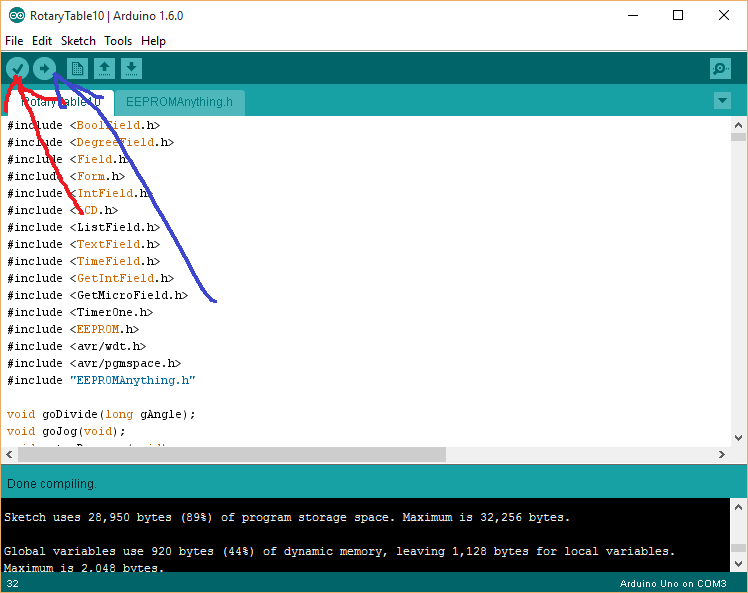

Click the Button marked with the Red Arrow to verify that the script will compile. This does not require an Arduino attached to your PC so you can get it compiling before you spend your money.

Then, grab yourself these things:

1. An Arduino Uno or equivalent

2. A Freetronics LCD display; see http://www.freetronics.com.au/collections/display/products/lcd-keypad-shield

3. A stepper controller

4. A stepper motor. NEMA 23 is a good size for a 6 inch Rotary table

5. Power supply (minimum 24 volt in my experience, around 80% of what you stepper driver is rated for - I use a 48 volt power supply).

With the LCD attached to your Arduino, plug your Arduino into a USB port, check your system is properly configured and hit the button pointed to by the blue arrow. The script will be recompiled and downloaded to your Arduino. The Arduino screen should light up after this process.

Connect up your stepper controller to the Arduino. making sure you are working on the low voltage side of the controller. You need to provide 5 volt power, ground and a step and direction port. The Arduino has enough current to drive the stepper controller.

Then connect power to the high voltage side of your controller and connect the wires correctly to your stepper motor.

Check the Setup menu and set up the step and direction ports to agree with those you chose when connecting your Arduino to the Stepper controller. Also set the various pulse parameters to suit your hardware.

Check the maxHz and MinHz settings in the setup folder. Start at around 5,000 and 9,000 (for Max and Min respectively or accept the defaults).

Makee sure you save the setup.

You should not need to touch the code to get it going as everything is set in the setup menu and stored in the EEPROM memory forever on the Arduino.

Note that the script also supports linear devices and multiple devices. via the new device function in setup. This simply creates a new numbered setup in the EEPROM. You can load devices at will to swap between devices when setup.

The main feature of this controller is that it uses interrupts for high performance and this also allows it to ramp up and down to speed so that it can overcome inertia by running slowly at maximum torque and ramping up to speed.

There are heaps of dividing functions, jogging and continuous turning. Some people have modified this script to alter the speed while continuous turning but on a 90:1 rotary table like mine, the maximum speed you are going to get is about 4 RPM so it is a bit pointless attempting to change the speed IMHO.

Anyway, I'm sure I've overlooked some stuff but please try this and report back. Just remember if you are not using a Freetronics LCD display and keyboard you are on your own!

View attachment RotaryTable10.zip

http://www.homemodelenginemachinist.com/showthread.php?p=273830#post273830

if you need more help but this thread is designed to provide a simple easy to install solution of version 10 of my Rotary Table controller.

I am going to assume you already have installed the Arduino IDE on your PC. Don't worry if you don't have an Arduino at this stage.

All you have to do is to find the Arduino folder in "My Documents". On my PC it was in this folder C:\Users\Rod\Documents\Arduino and unzip the attached file into it. I am guessing that you have a different name to me so it will be a bit different on your PC

So you should now have the following folders in the Arduino folder

C:\Users\Rod\Documents\Arduino\libraries

C:\Users\Rod\Documents\Arduino\RotaryTable10

In the Libraries folder you should find the following folders

C:\Users\Rod\Documents\Arduino\libraries\LCD

C:\Users\Rod\Documents\Arduino\libraries\TimerOne-r11

In the C:\Users\Rod\Documents\Arduino\RotaryTable10 folder you will find the following files:

EEPROMAnything.h

RotaryTable10.ino

Assuming you have the Arduino IDE installed on your PC if you double click on

RotaryTable10.ino and it should open in the IDE.

Click the Button marked with the Red Arrow to verify that the script will compile. This does not require an Arduino attached to your PC so you can get it compiling before you spend your money.

Then, grab yourself these things:

1. An Arduino Uno or equivalent

2. A Freetronics LCD display; see http://www.freetronics.com.au/collections/display/products/lcd-keypad-shield

3. A stepper controller

4. A stepper motor. NEMA 23 is a good size for a 6 inch Rotary table

5. Power supply (minimum 24 volt in my experience, around 80% of what you stepper driver is rated for - I use a 48 volt power supply).

With the LCD attached to your Arduino, plug your Arduino into a USB port, check your system is properly configured and hit the button pointed to by the blue arrow. The script will be recompiled and downloaded to your Arduino. The Arduino screen should light up after this process.

Connect up your stepper controller to the Arduino. making sure you are working on the low voltage side of the controller. You need to provide 5 volt power, ground and a step and direction port. The Arduino has enough current to drive the stepper controller.

Then connect power to the high voltage side of your controller and connect the wires correctly to your stepper motor.

Check the Setup menu and set up the step and direction ports to agree with those you chose when connecting your Arduino to the Stepper controller. Also set the various pulse parameters to suit your hardware.

Check the maxHz and MinHz settings in the setup folder. Start at around 5,000 and 9,000 (for Max and Min respectively or accept the defaults).

Makee sure you save the setup.

You should not need to touch the code to get it going as everything is set in the setup menu and stored in the EEPROM memory forever on the Arduino.

Note that the script also supports linear devices and multiple devices. via the new device function in setup. This simply creates a new numbered setup in the EEPROM. You can load devices at will to swap between devices when setup.

The main feature of this controller is that it uses interrupts for high performance and this also allows it to ramp up and down to speed so that it can overcome inertia by running slowly at maximum torque and ramping up to speed.

There are heaps of dividing functions, jogging and continuous turning. Some people have modified this script to alter the speed while continuous turning but on a 90:1 rotary table like mine, the maximum speed you are going to get is about 4 RPM so it is a bit pointless attempting to change the speed IMHO.

Anyway, I'm sure I've overlooked some stuff but please try this and report back. Just remember if you are not using a Freetronics LCD display and keyboard you are on your own!

View attachment RotaryTable10.zip