digiex-chris

Well-Known Member

- Joined

- Dec 6, 2010

- Messages

- 263

- Reaction score

- 58

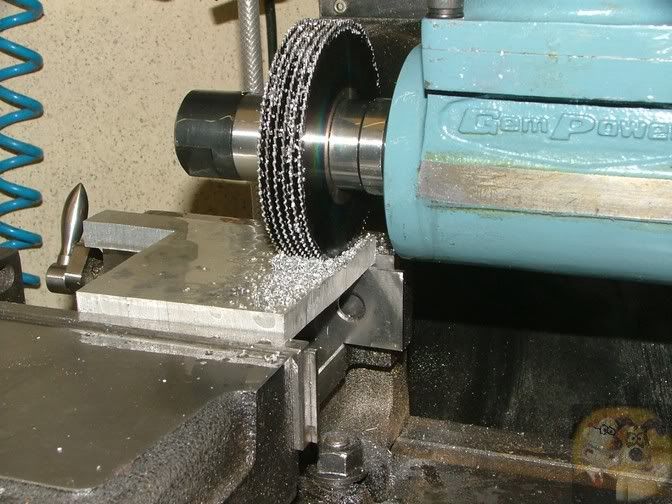

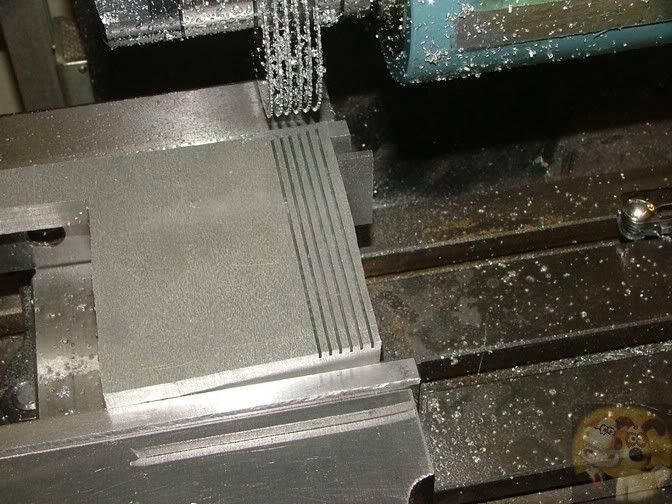

1) That wasn't the slitting saw I wanted, it was a wood cutting saw that ended up in that cabinet drawer. Oops. I figure it burned the teeth off immediately, and then I pushed harder.

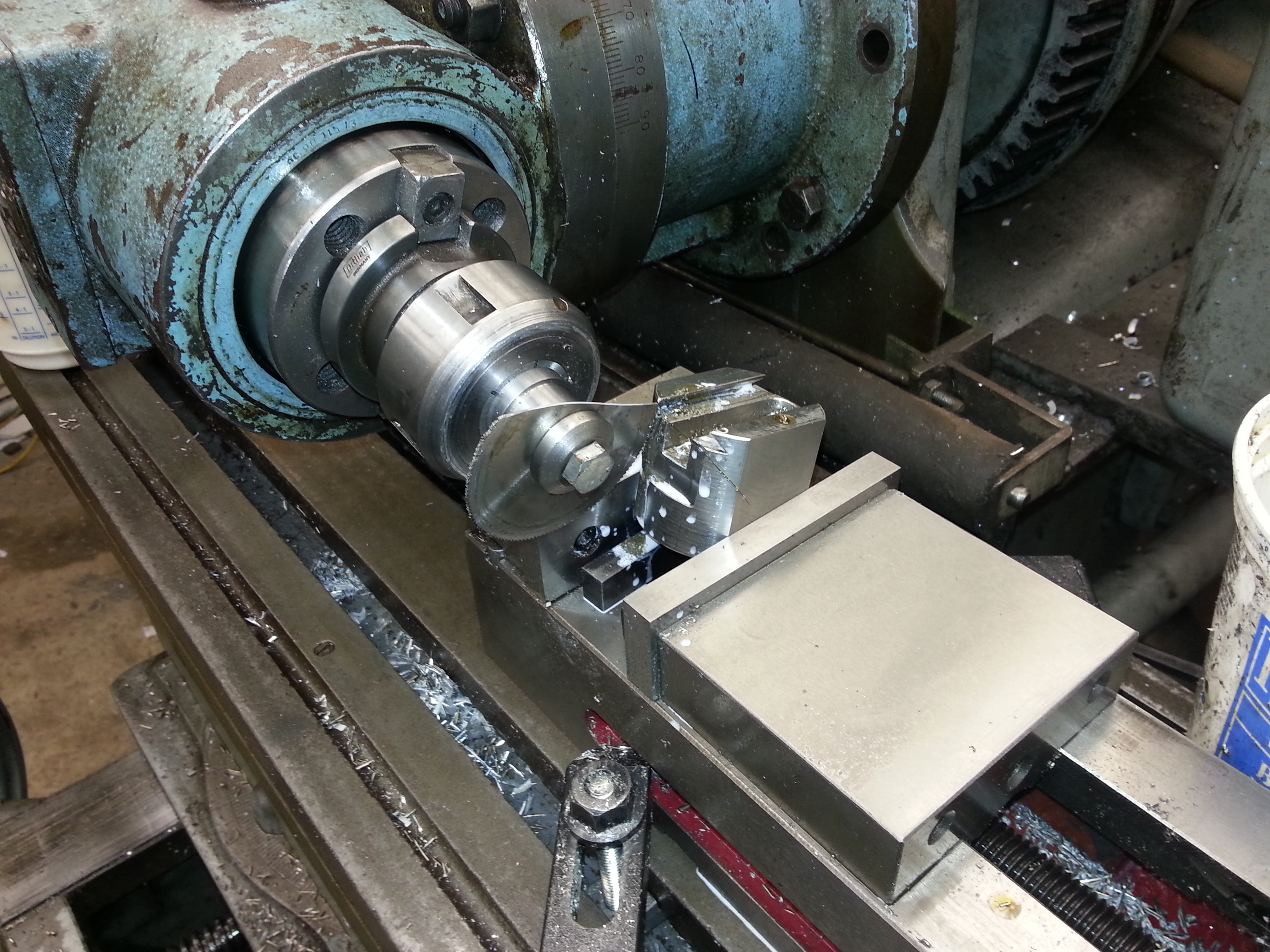

2) My cheap vise doesn't hold very well, the fixed jaw stretches the bolts and flexes away.

3) a 1/3 absent slitting saw with the remaining teeth burned off, with a bit of an edge ground on to it and a bit of relief behind it, can still finish the cut , if you're willing to feed it less than a thousandth per rev. Man does it make a racket though...