Philipintexas

Well-Known Member

- Joined

- Apr 13, 2012

- Messages

- 227

- Reaction score

- 52

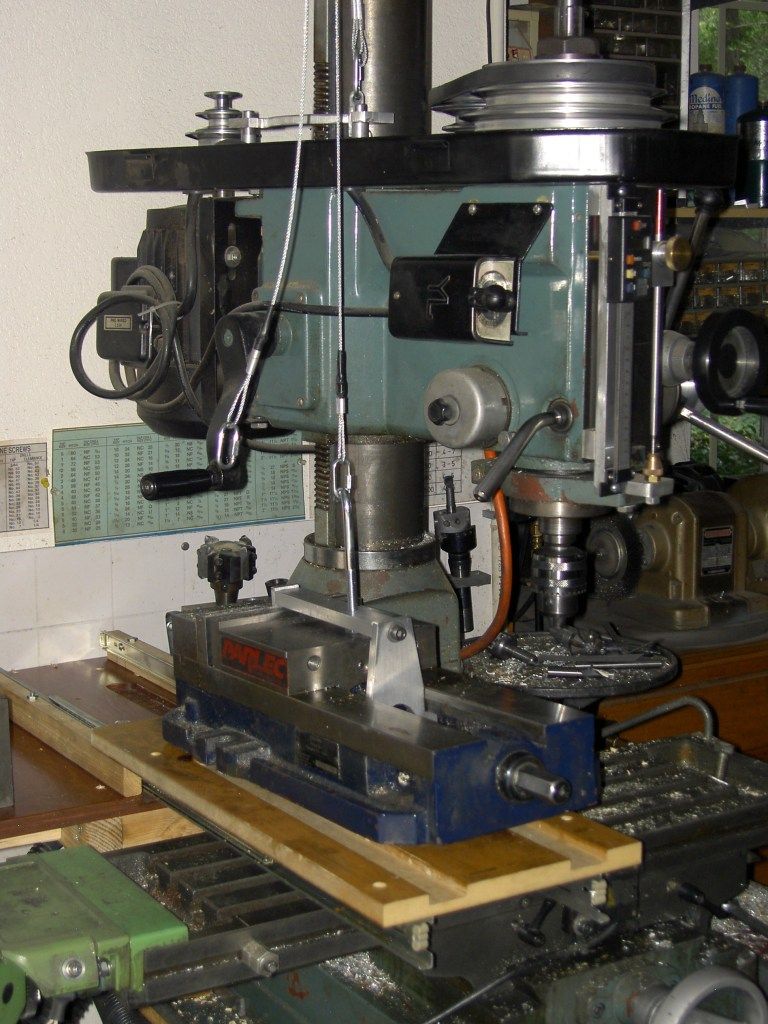

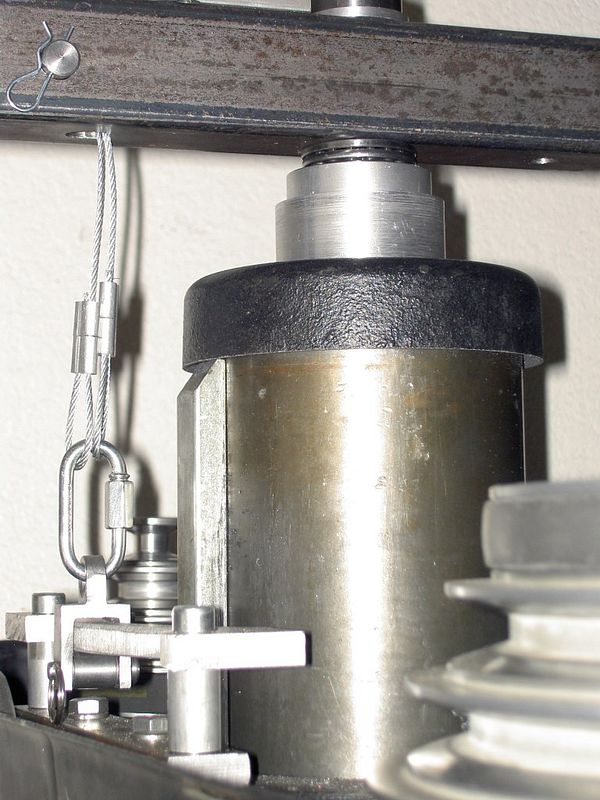

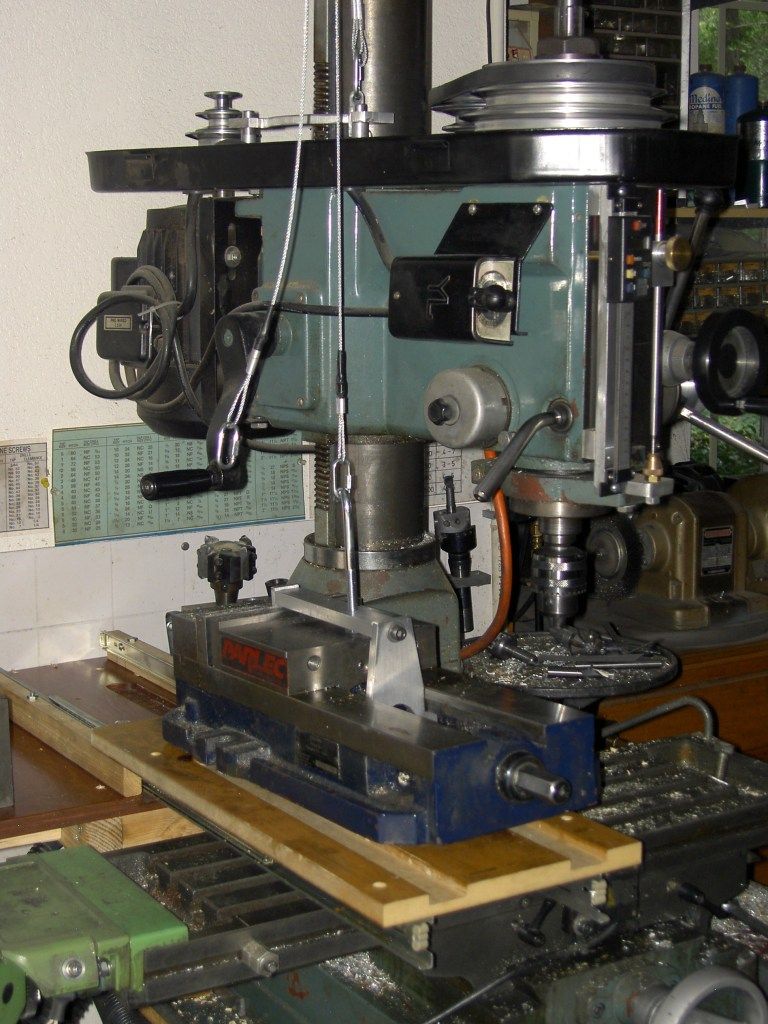

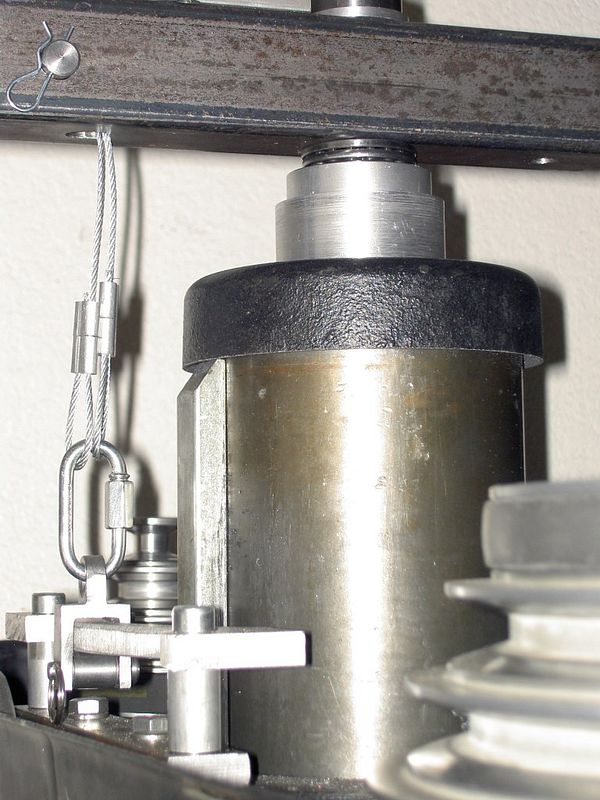

Either I'm getting weaker as I age or my milling machine vise (was 80 Lbs.) is getting heavier because lifting it to my table height of 42" has become a real chore. Exchanging it with my 75 Lb. rotary-table is a procedure I've come to dread. With that motivation and some spare time I decided to make it easier. I first added a shelf behind the left side of the table at the same height as the mill table. I used a 100 Lb. capacity ball-bearing drawer slide to make a pull out shelf for vise storage. There are lots of different hoist ideas but I wanted to keep mine simple so I hit on the idea of using the 150 Lb. weight of the mill head to do all the heavy lifting. I fashioned a 24" arm of 1-3/4" X 1/8" steel square tube and attached it to the top of the column supported on a used vise thrust bearing and a ball bearing on top raised enough to clear the pulleys & belts. My column has a substantial lip at the top so I was able to insert a steel plate threaded 1/2" X 13 under the lip to secure everything. Conveniently there were 2 bolts near where I wanted to attach the lift cables so I made a semi-circular track with a roller trolley to permit swinging the arm while loaded. I had to make a frame for the vise to allow lifting at its center of gravity, and a similar hook for the rotary table. I turned three self-centering rollers on 1/2" axles inside the arm for the cables. Now I can move the Mill-table to the left, hook up the vise to the inner cable, and effortlessly lower the mill-head a couple inches, which raises the vise the same amount, pull out the sliding shelf, lower the vise, unhook the cable and slide the shelf away from the table. Similar procedure using the outboard cable to pick up the rotary-table and swing it to the mill-table. No more sore back. I recognize the safety issue of not using the belt guard but I've lost it over the years, and my belts are over my head anyway.