Hello All,

My name is Lance, been lurking:hDe: here since :fan: and been waiting for the air to clear to introduce myself.

I'm 53 and have been into hit and miss engines since I was 12 or 13. I grew up in NE OHIO and ran the PA oilfields most of my teen years. I used to go to coolspring when it was a pole barn and a couple of sheds. I've had hit and miss engines all of my life up till a couple years ago, I sold the last one, getting to heavy for an old man with a bad back to move around.

Ive always wanted models, been a mechanic all of my life. A month ago the landlord at my shop started cleaning out a storage area for a new renter, and came dragging out an Enco 109-1005 mini lathe/mill on a forklift. $400.00 later he set it in my shop. After a lot of cleaning, rewiring and adjusting, it's working but has .004 play on the x axis and .006 play on the y axis. So I promptly ordered a 3 axis dro so I know where I'm at because I can trust the feed wheels. Kinda feel like an old edsel owner, can't find parts for this machine anywhere.:wall: Needs the brass/bronze feed bushings to get rid of the play, but I think I'll have to make them, and my machining skills/tooling are not there yet!

It came with all of the gears, wrenches, the original bits(they look like a metal eating dog gnawed on the cutting ends) a few countersinks for the mill and some india lathe bits that might be good for wood.

Found a rotary table with dividing plates at a good price, not that I need that right away, but could not pass up a good deal.

Also in the buildings where my shop is at, there is a weld/fab shop, so naturally I've been over scrounging some good scraps.

I must say most of the work I have seen on here is outstanding to say the least, just hope I can get my skills somewhere close to what I have seen.

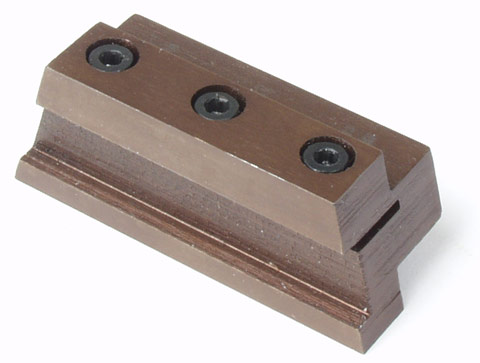

I hope you all will will help a newbie, through the learning/spending curve. So I might as well start off with my first Question. The toolpost is a 4 way 1/2" bit. What kind of tool holder do I need for a parting tool?

Anyways thanks for having me here and I hope to learn a lot, and maybe contribute what i can in the way of hit and miss mechanical knowledge, restored more of them than I could keep track of.

Thanks again

Lance

My name is Lance, been lurking:hDe: here since :fan: and been waiting for the air to clear to introduce myself.

I'm 53 and have been into hit and miss engines since I was 12 or 13. I grew up in NE OHIO and ran the PA oilfields most of my teen years. I used to go to coolspring when it was a pole barn and a couple of sheds. I've had hit and miss engines all of my life up till a couple years ago, I sold the last one, getting to heavy for an old man with a bad back to move around.

Ive always wanted models, been a mechanic all of my life. A month ago the landlord at my shop started cleaning out a storage area for a new renter, and came dragging out an Enco 109-1005 mini lathe/mill on a forklift. $400.00 later he set it in my shop. After a lot of cleaning, rewiring and adjusting, it's working but has .004 play on the x axis and .006 play on the y axis. So I promptly ordered a 3 axis dro so I know where I'm at because I can trust the feed wheels. Kinda feel like an old edsel owner, can't find parts for this machine anywhere.:wall: Needs the brass/bronze feed bushings to get rid of the play, but I think I'll have to make them, and my machining skills/tooling are not there yet!

It came with all of the gears, wrenches, the original bits(they look like a metal eating dog gnawed on the cutting ends) a few countersinks for the mill and some india lathe bits that might be good for wood.

Found a rotary table with dividing plates at a good price, not that I need that right away, but could not pass up a good deal.

Also in the buildings where my shop is at, there is a weld/fab shop, so naturally I've been over scrounging some good scraps.

I must say most of the work I have seen on here is outstanding to say the least, just hope I can get my skills somewhere close to what I have seen.

I hope you all will will help a newbie, through the learning/spending curve. So I might as well start off with my first Question. The toolpost is a 4 way 1/2" bit. What kind of tool holder do I need for a parting tool?

Anyways thanks for having me here and I hope to learn a lot, and maybe contribute what i can in the way of hit and miss mechanical knowledge, restored more of them than I could keep track of.

Thanks again

Lance