- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

Waiting on parts before I can continue on my outstanding projects, so what do I do??? I ordered some more parts for yet another project!

http://www.ebay.com/itm/321195442688?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649

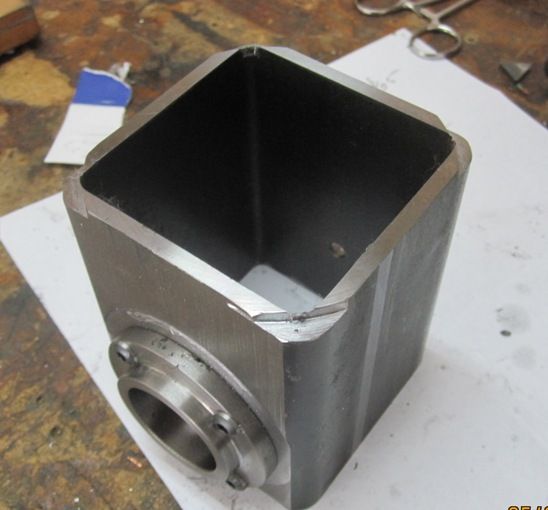

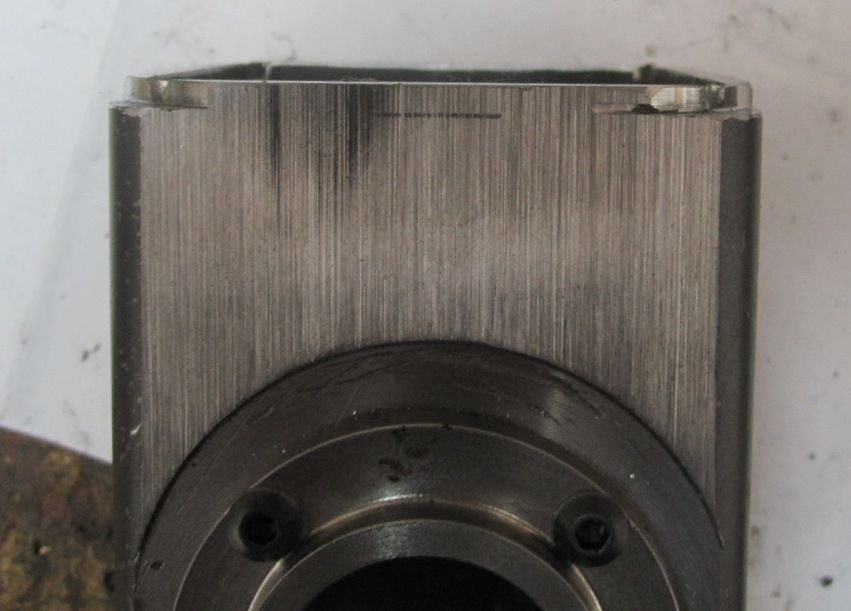

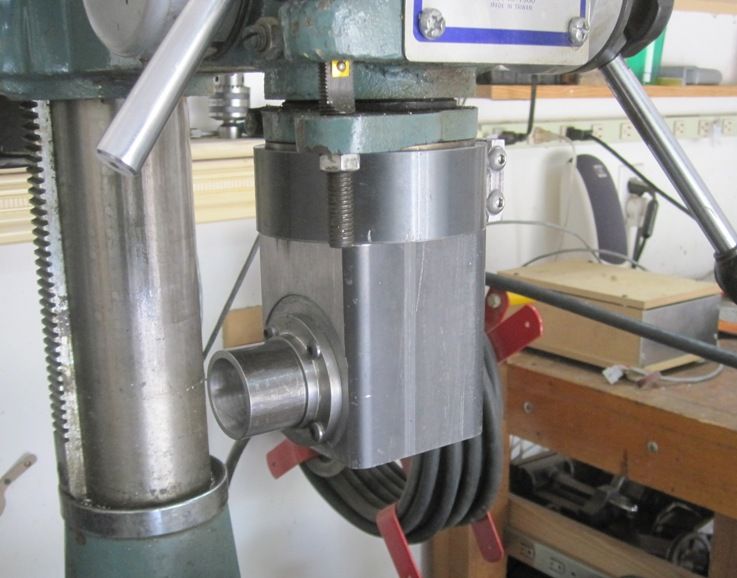

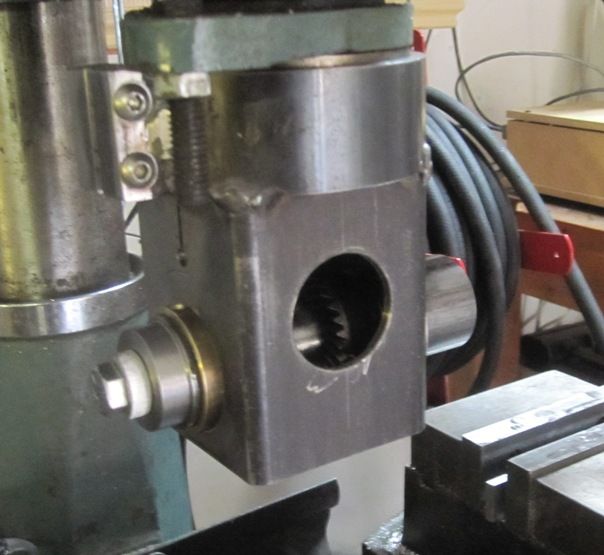

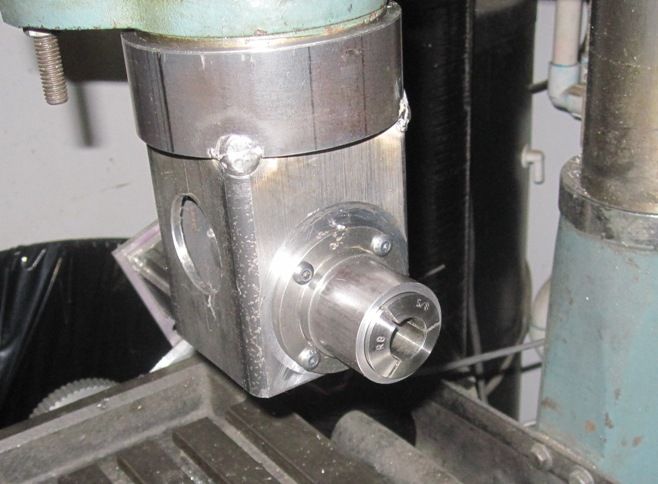

In their March 1995 issue, Home Shop Machinist featured a 2-part article by Frank McClean on building a horizontal milling attachment for his mill / drill. Using bevel gears like those in the article would be pretty expensive, probably topping $60 or more if ordered from some place like Stock Drive Products. However, there are a myriad of bevel gear sets available on Ebay in many different sizes and shapes as replacements for angle grinders and hammer drills. So, if everything pans out, I'm going to give it a shot. I doubt it will handle heavy duty milling, but it should drive slitting saws and involute gear cutters with no problem.

Stay tuned...

Chuck

http://www.ebay.com/itm/321195442688?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649

In their March 1995 issue, Home Shop Machinist featured a 2-part article by Frank McClean on building a horizontal milling attachment for his mill / drill. Using bevel gears like those in the article would be pretty expensive, probably topping $60 or more if ordered from some place like Stock Drive Products. However, there are a myriad of bevel gear sets available on Ebay in many different sizes and shapes as replacements for angle grinders and hammer drills. So, if everything pans out, I'm going to give it a shot. I doubt it will handle heavy duty milling, but it should drive slitting saws and involute gear cutters with no problem.

Stay tuned...

Chuck