You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Horizontal Mill Engine From Kit

- Thread starter zeeprogrammer

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Well, Well, Well !!!!

I just finished reading this thread.

Yup, the whole thing. Every page.

What an educational and fun tour !!!

My thanks go to everyone who posted with information, how-to's and humour.

As for Zee:

Even though you pretend differently you are one self confident and gutsy fellow to expose yourself as you have.

A job well done. :bow:

I do believe that this thread, all by itself, has convinced me to get a shop in order and start building my own engines.

Earl...

As to the kit:

I see that it sells for $79.95 and weighs 3.93 lbs.

$79.95 / 3.93 = $20.34 per pound.

It seems like at that price-per-pound they would have incentive to include a little extra material for you to hang on to.

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

potman said:I do believe that this thread, all by itself, has convinced me to get a shop in order and start building my own engines.

Earl...Thank you very much. To have positively influenced someone is about the greatest praise I can think of. I really appreciate your post. And like you said, everyone who's posted on here has made this thread possible and earned that praise.

Self-confident and gutsy? No...I've always struggled with a lack of confidence. For me it's been more persistence and determination. I've thought about this since I was a kid...it was literally now or never.

And I can't say enough about the members on this forum. What success I've had, and fun, has very much depended on them.

Put that shop together! Do it! Make engines!

Thanks again Earl. I look forward to seeing your shop take shape and engines being built.

P.S. Yeah...the kit's not a great deal. You can get the same (but better) plans on the internet. And if you're like me starting out, you'll be remaking some parts and have to buy more material anyway. And, while the instruction manual has several issues, it was better than nothing for someone that knew absolutely nothing about lathes, mills, and machining.

Krown Kustoms

Well-Known Member

- Joined

- Aug 6, 2009

- Messages

- 313

- Reaction score

- 2

Very nice Zee, I havent posted much lately but I have been following.

Well Done, a few tweaks and she will run nicely

-B-

Well Done, a few tweaks and she will run nicely

-B-

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Thanks for watching -B-.

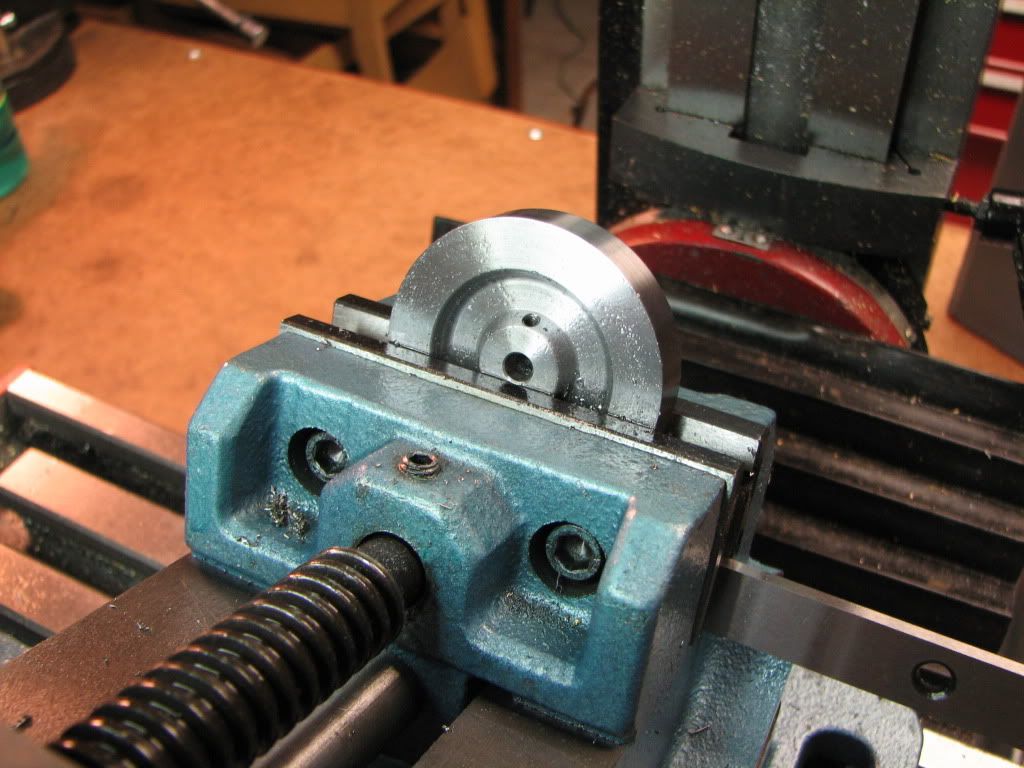

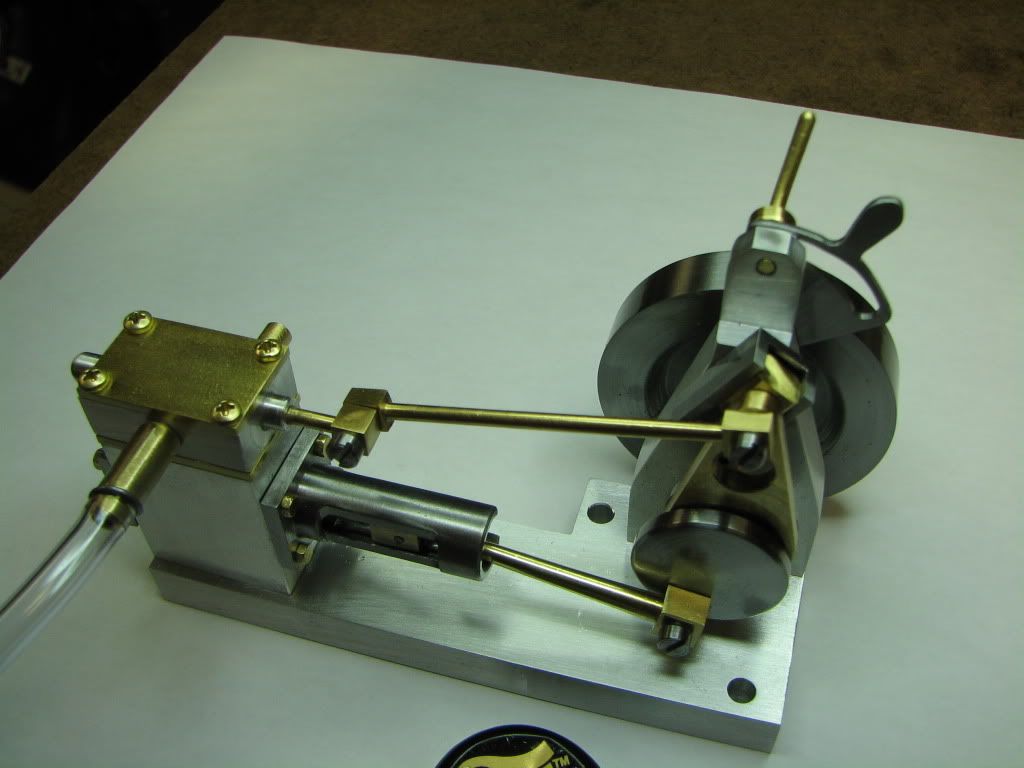

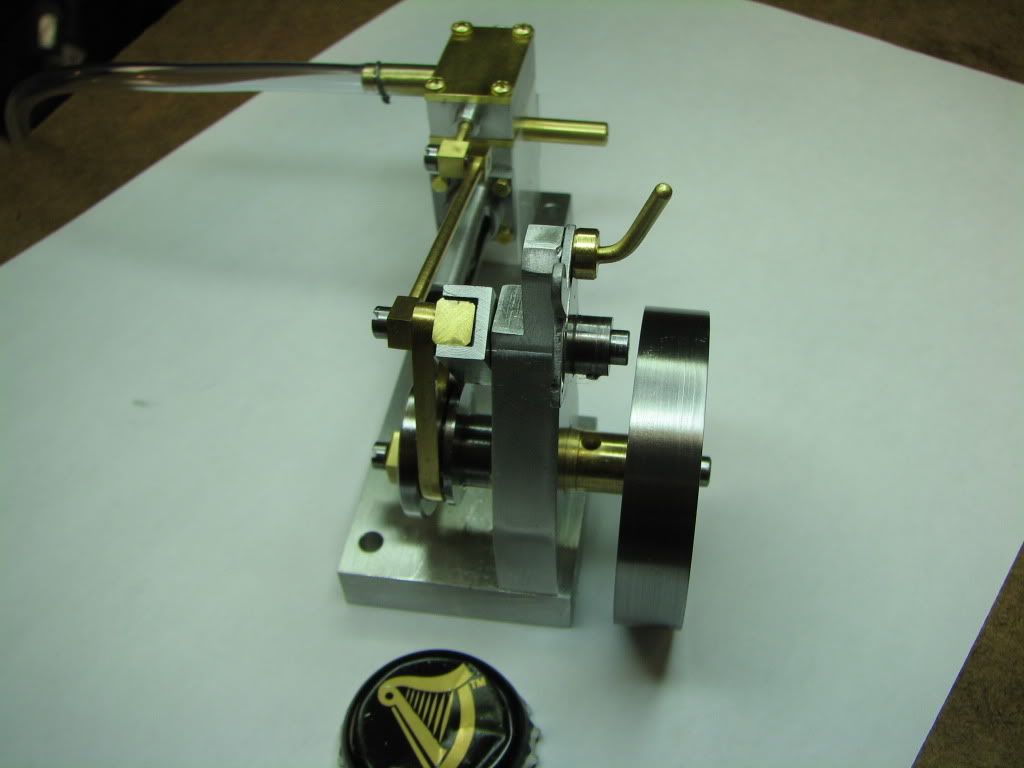

Finally got the new flywheel done. The one I did for the Launch Engine was a whole lot easier. Maybe it's because of the troubles I'm having with the lathe (brushes, control board, or something). But most likely I'm forgetting something...proper speed, height of cutter, etc. In any case...here it is...

Dinged the side of the flywheel when I went to drill for the set screw but was able to sand it out okay.

Forgot to support the wheel on a parallel or something and noticed the wheel move down as I started to drill. Luckily I saw it in time, stopped, put a parallel in place, readjusted and then things went very nicely.

Something else I've noticed...early in the project I broke a 3-48 tap that I had gotten in a set of miniature taps. I ordered two replacement taps from the same supplier. They look slightly different. More importantly they cut steel almost as if it was butter. I wonder if it's another example showing you're better off to buy a tool as you need it. (Although I've used everything from the kit except the 0-80.)

Now it's time to reassemble and starting running it in some more. (First though I want to sand and smooth up the connecting rod.)

Still need a replacement for my 'happy dance tune'...

Finally got the new flywheel done. The one I did for the Launch Engine was a whole lot easier. Maybe it's because of the troubles I'm having with the lathe (brushes, control board, or something). But most likely I'm forgetting something...proper speed, height of cutter, etc. In any case...here it is...

Dinged the side of the flywheel when I went to drill for the set screw but was able to sand it out okay.

Forgot to support the wheel on a parallel or something and noticed the wheel move down as I started to drill. Luckily I saw it in time, stopped, put a parallel in place, readjusted and then things went very nicely.

Something else I've noticed...early in the project I broke a 3-48 tap that I had gotten in a set of miniature taps. I ordered two replacement taps from the same supplier. They look slightly different. More importantly they cut steel almost as if it was butter. I wonder if it's another example showing you're better off to buy a tool as you need it. (Although I've used everything from the kit except the 0-80.)

Now it's time to reassemble and starting running it in some more. (First though I want to sand and smooth up the connecting rod.)

Still need a replacement for my 'happy dance tune'...

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

So many songs...so many memories...

Mary Poppins...Spoonful of Sugar...I was in the Boys Choir...in my robe, lined up to go on stage opening night...started coughing...couldn't stop...they pulled me out. Turned out I had strep. After I got over that. I was no longer a boy. Ah well.

Twist and Shout...Made me think of Chubby's 'The Twist' (he doesn't live too far from here). Won the Twist contest at the AYA. Got an ice cream cone. Ah well.

:big:

Mary Poppins...Spoonful of Sugar...I was in the Boys Choir...in my robe, lined up to go on stage opening night...started coughing...couldn't stop...they pulled me out. Turned out I had strep. After I got over that. I was no longer a boy. Ah well.

Twist and Shout...Made me think of Chubby's 'The Twist' (he doesn't live too far from here). Won the Twist contest at the AYA. Got an ice cream cone. Ah well.

:big:

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

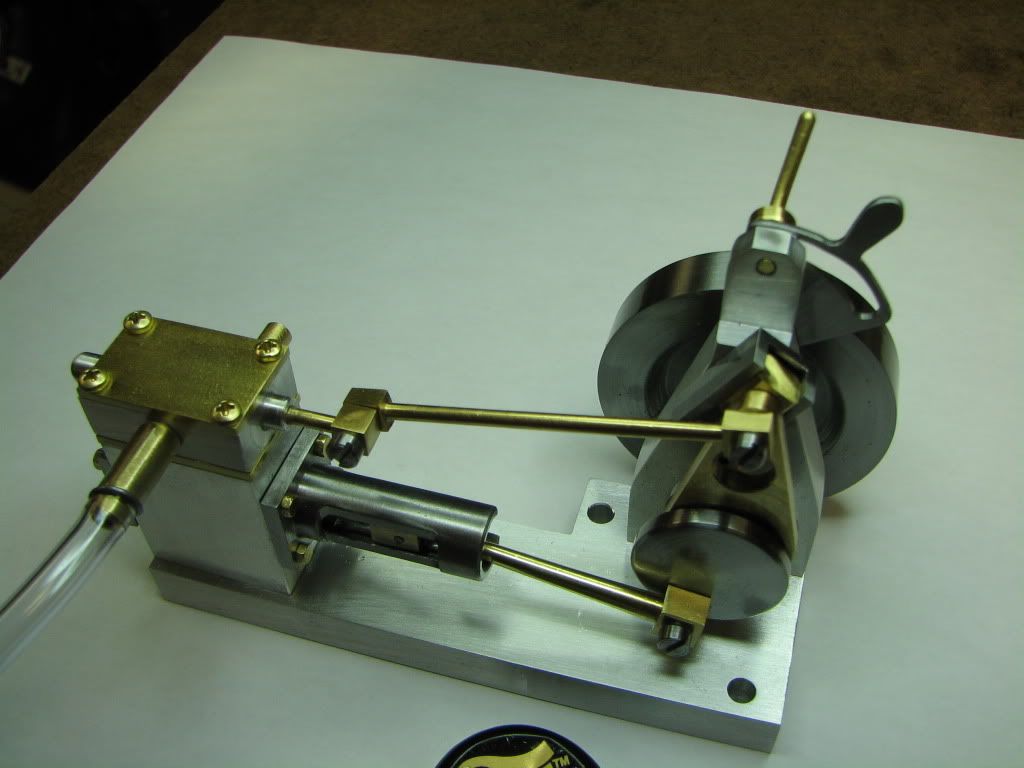

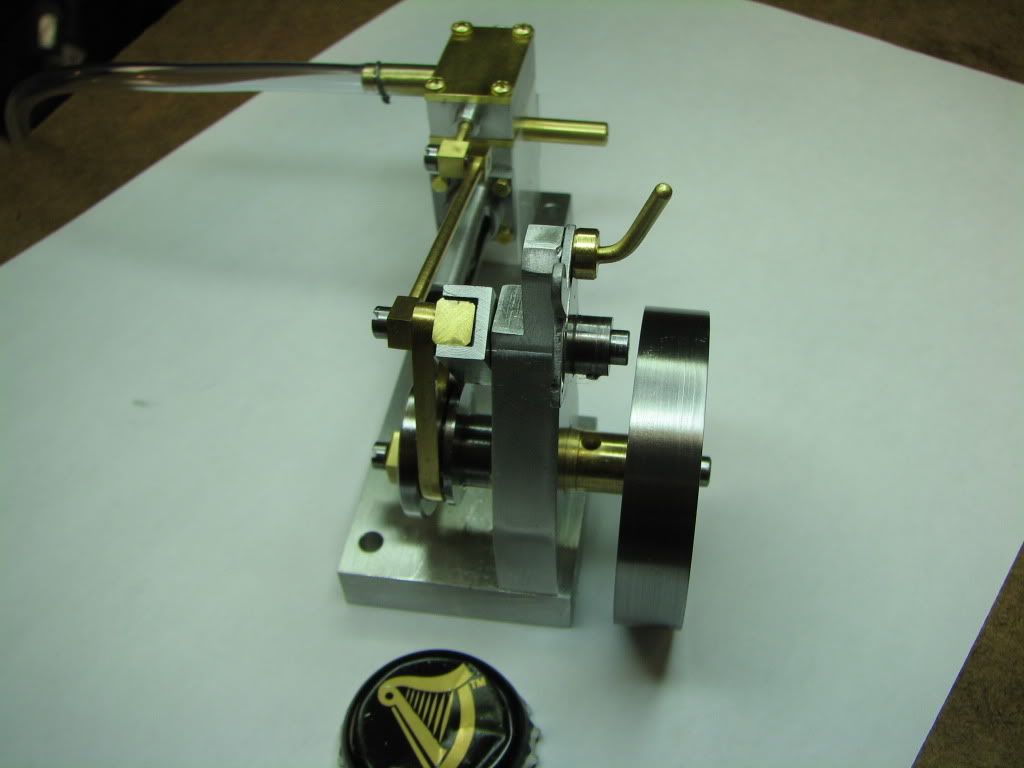

IT'S NOT DONE!!!! but here's some pics of it assembled. It's being run in on air in one direction right now...

[EDIT: Runs great in one direction. Low PSI too. Has some bad binding in the other direction though. Doesn't run on air. I can put a rubber band coated drill up to the flywheel. A little better but still stops immediately when I remove the drill.

Tweaky tweaky tweaky...]

[EDIT: Runs great in one direction. Low PSI too. Has some bad binding in the other direction though. Doesn't run on air. I can put a rubber band coated drill up to the flywheel. A little better but still stops immediately when I remove the drill.

Tweaky tweaky tweaky...]

Congratulations Zee, that's a real nice looking engine. Bet you can't believe how far you've come in a year - I've been hanging around the forum for about the same amount of time and have yet to start my first build :-[ Must get myself into gear for 2010 !!

Powder keg

Well-Known Member

- Joined

- Oct 10, 2007

- Messages

- 1,091

- Reaction score

- 3

Keep it up ZEE!! Looks great!!!!!

arnoldb

Well-Known Member

- Joined

- Apr 8, 2009

- Messages

- 1,792

- Reaction score

- 12

What do you mean it's not done yet? - and you are doing just what else to it right now, without a video *knuppel2*?IT'S NOT DONE!!!! but here's some pics of it assembled. It's being run in on air in one direction right now...

Just teasing Zee - your creation is really really beautiful, and a very good example of craftsmanship IMO. I could call it "pretty" - but pretty is skin deep and there's a lot more here than just the outside appearance to appreciate!

Kind regards, Arnold

mklotz

Well-Known Member

Very nice work, Zee. It looks very professional. That's a helluva lot of progress for less than a year.

With that engine it's easy to disconnect, one at a time, the valve connecting rod and the piston connecting rod while turning the engine over in the direction in which it binds. That should help localize the problem quickly.

You may also want to install the plexi steam chest cover to see if anything is binding up in there - although I doubt that that's the problem.

With that engine it's easy to disconnect, one at a time, the valve connecting rod and the piston connecting rod while turning the engine over in the direction in which it binds. That should help localize the problem quickly.

You may also want to install the plexi steam chest cover to see if anything is binding up in there - although I doubt that that's the problem.

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Thanks JimM...and get busy!

Thanks Powder Keg.

Thanks Arnold..patience patience.

Thanks Marv. Yeah...that's exactly what I did. The first issue was in the piston guide at one end. I loosened the cylinder and shoved it back as far as it would go and that loosened things up pretty nice. I think it's still touchy so might have to file the holes a little (slot them a little). With that change, the system turns over pretty easily by hand.

I've got the plexi steam chest on it now (and thanks again for a great idea). Nothing binding but I think it's not well adjusted. So I'm going to play with that next. When the reversing lever is at one end...it works pretty well. But at the other end it's as if both ports are getting air at the same time. Turning the flywheel gives resistance.

Unfortunately I've been called for Christmas cookie duty and must go shopping right now. Wife comes home tonight and she and daughter are going to make cookies tomorrow. Come to think about it...that's not unfortunate...I get cookies!

Thanks Powder Keg.

Thanks Arnold..patience patience.

Thanks Marv. Yeah...that's exactly what I did. The first issue was in the piston guide at one end. I loosened the cylinder and shoved it back as far as it would go and that loosened things up pretty nice. I think it's still touchy so might have to file the holes a little (slot them a little). With that change, the system turns over pretty easily by hand.

I've got the plexi steam chest on it now (and thanks again for a great idea). Nothing binding but I think it's not well adjusted. So I'm going to play with that next. When the reversing lever is at one end...it works pretty well. But at the other end it's as if both ports are getting air at the same time. Turning the flywheel gives resistance.

Unfortunately I've been called for Christmas cookie duty and must go shopping right now. Wife comes home tonight and she and daughter are going to make cookies tomorrow. Come to think about it...that's not unfortunate...I get cookies!

mklotz

Well-Known Member

When the reversing lever is at one end...it works pretty well. But at the other end it's as if both ports are getting air at the same time. Turning the flywheel gives resistance.

It's conceivable that the valve slide (the U-shaped channel in which the valve rod actuator slides) is not correctly aligned with the slotted reversing lever.

Try this experiment. With air applied and the reversing lever in the position where you're having trouble, try moving the reversing lever in small angular increments, locking, and then trying to get the engine running. You may find a spot where it wants to run.

Alternatively, and perhaps simpler to do, measure the angle the U-channel makes with horizontal/vertical at each extreme ot the reversing lever motion. The angle should be about the same.

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

1) Okay Zee, do your shopping, and what ever else you need to do.

2) Make any necessary adjustments on your build.

3) Finalize your build thread with a VIDEO.

4) No MILK & COOKIES for you, until you complete steps 1 thru 3! ;D

-MB

2) Make any necessary adjustments on your build.

3) Finalize your build thread with a VIDEO.

4) No MILK & COOKIES for you, until you complete steps 1 thru 3! ;D

-MB

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Step 1: Completed...but I busted a bag of flour. I hope we have enough. Darn it...I can see into the pantry from here...we already have two bags of flour and sugar. She's going to kill me.

Step 2: In progress. Was working on it and it suddenly started having that same binding issue at the far end of a stroke. Took the cylinder cover off. Rats...piston is unthreading itself...effectively lengthening the piston/rod until it bangs into the cylinder cover. I'm thinking super glue. Wouldn't I still be able to remove the piston? Easier than Loctite? That's all I got. Well...Elmer's White...some gum...spit?

Step 3: There WILL be video.

Step 4: Awwwwww maaaaan!

Step 2: In progress. Was working on it and it suddenly started having that same binding issue at the far end of a stroke. Took the cylinder cover off. Rats...piston is unthreading itself...effectively lengthening the piston/rod until it bangs into the cylinder cover. I'm thinking super glue. Wouldn't I still be able to remove the piston? Easier than Loctite? That's all I got. Well...Elmer's White...some gum...spit?

Step 3: There WILL be video.

Step 4: Awwwwww maaaaan!

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

zeeprogrammer said:Step 1: Completed...but I busted a bag of flour. I hope we have enough. Darn it...I can see into the pantry from here...we already have two bags of flour and sugar. She's going to kill me.

Step 2: In progress. Was working on it and it suddenly started having that same binding issue at the far end of a stroke. Took the cylinder cover off. Rats...piston is unthreading itself...effectively lengthening the piston/rod until it bangs into the cylinder cover. I'm thinking super glue. Wouldn't I still be able to remove the piston? Easier than Loctite? That's all I got. Well...Elmer's White...some gum...spit?

Step 3: There WILL be video.

Step 4: Awwwwww maaaaan!

Hide the extra flour in your shop! The women folk never snoop around down there.. too messy!

Use just a tiny bit of the blue loctite, you should be able to take it apart. Don't degrease the threads and the bond will be weak.

I can't wait to see the video.

Don't forget the video!

Did I mention the VIDEO?

V...I...D...E...O... ;D

-MB

mklotz

Well-Known Member

Blue threadlocker Loctite can be disassembled with hand tools. Keep some of it along with the permanent (red?) threadlocker and the green Bearing Fit Assist in every toolbox. You'll be surprised how often you make use of all of them.

I laugh on your "Big azz snow storm". Pennsylvania weather drove me to California. Right now (1330 PST), the indoor/outdoor thermometer on my desk reads 71 degF on both scales. Another Xmas dinner on the patio is a definite possibility.

I laugh on your "Big azz snow storm". Pennsylvania weather drove me to California. Right now (1330 PST), the indoor/outdoor thermometer on my desk reads 71 degF on both scales. Another Xmas dinner on the patio is a definite possibility.

Similar threads

- Replies

- 13

- Views

- 1K