That's a heck of a good price. If you can put a longer scale in it some how, would be great. My 18" scale for my lathe w/o the display was better than a $100. Nice find gentlemen. As usual a day late and $1 short.............

Matt

Matt

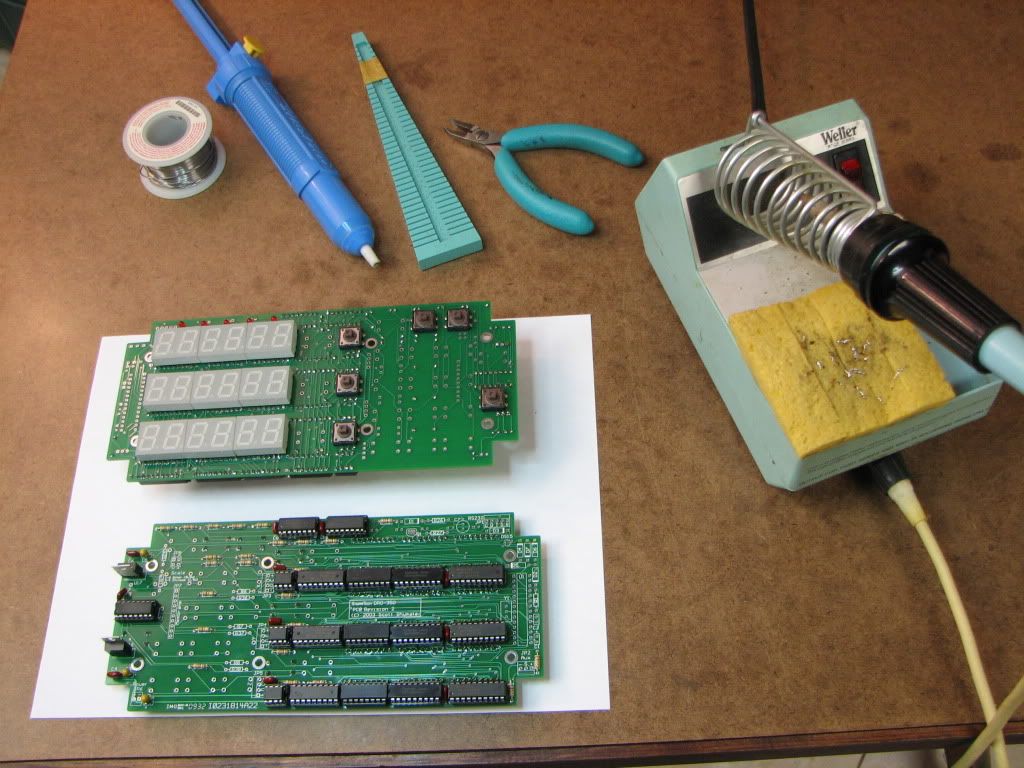

JimM said:What's the blue pyramid shaped thing next to the cutters in your pic?

zeeprogrammer said:Just a quickie post...

Found another pin I missed soldering...either eyesight or I can't count anymore (which might help Dean with the M&Ms).

hobby said:Electron current from neg. to pos. But your just pulling our leg on that one.

Maryak said:Glad your having fun

Enter your email address to join: