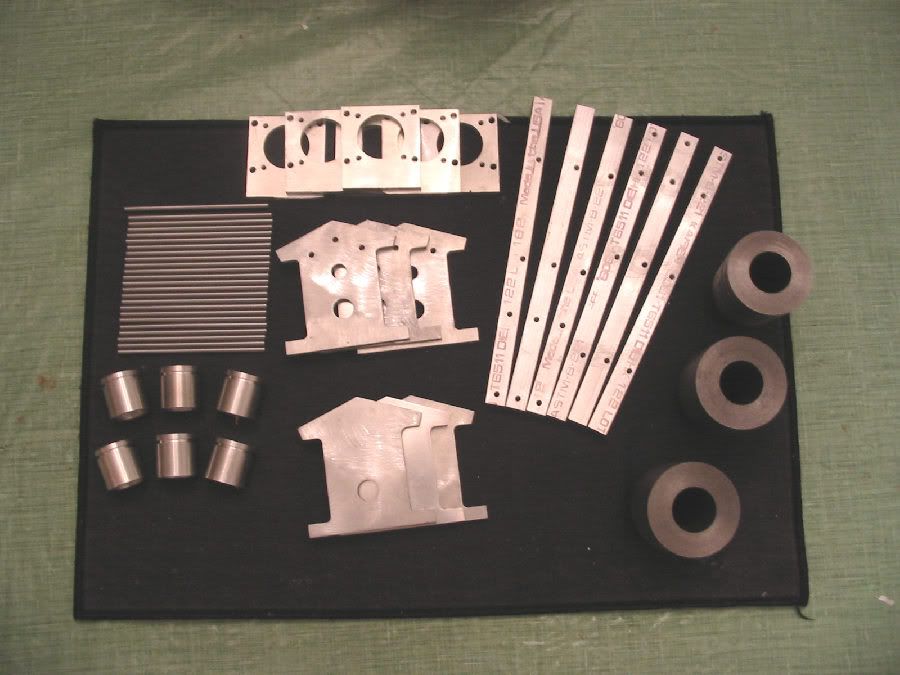

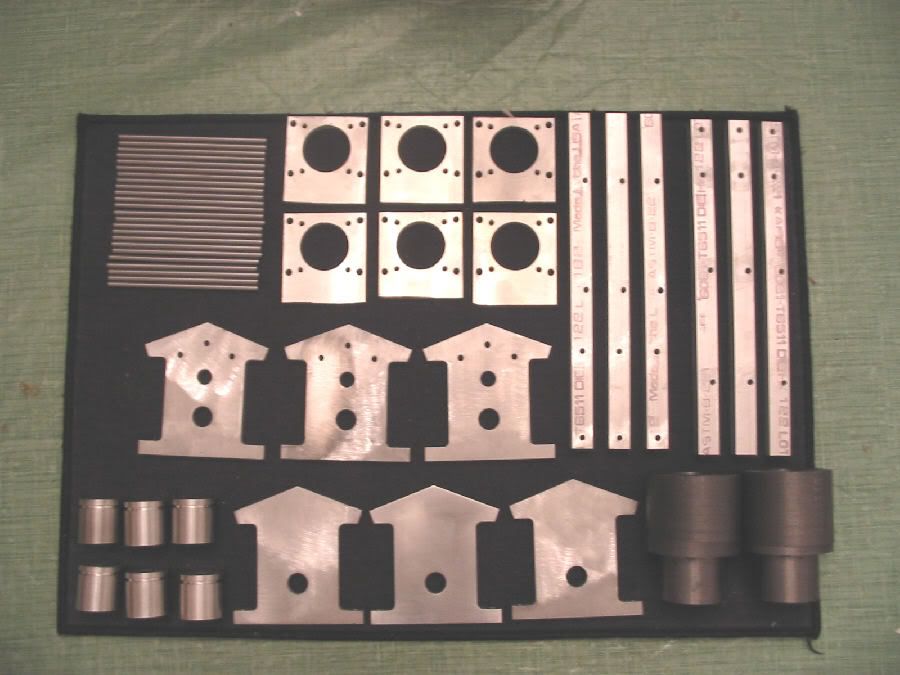

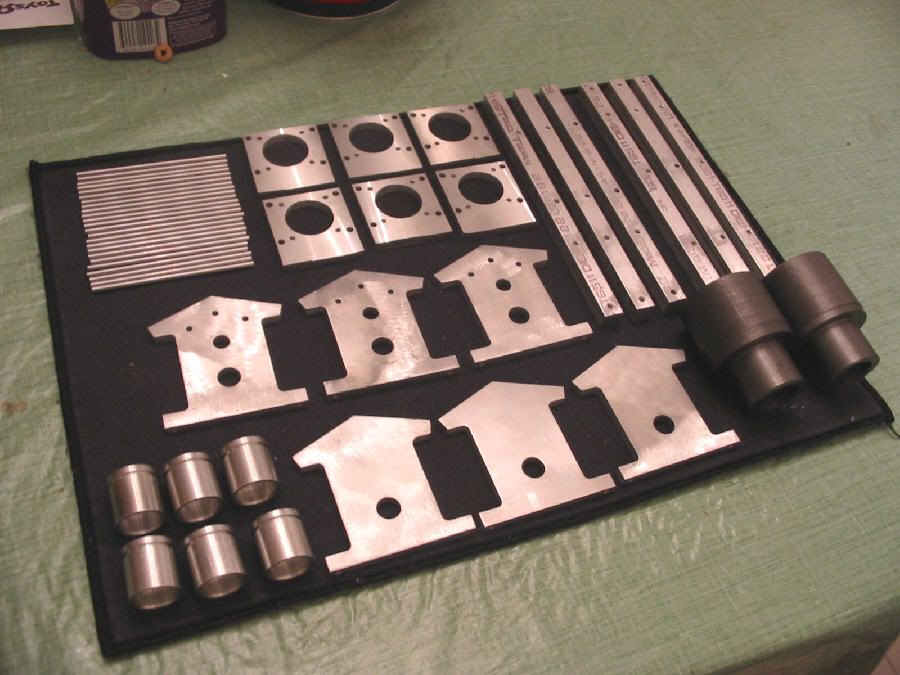

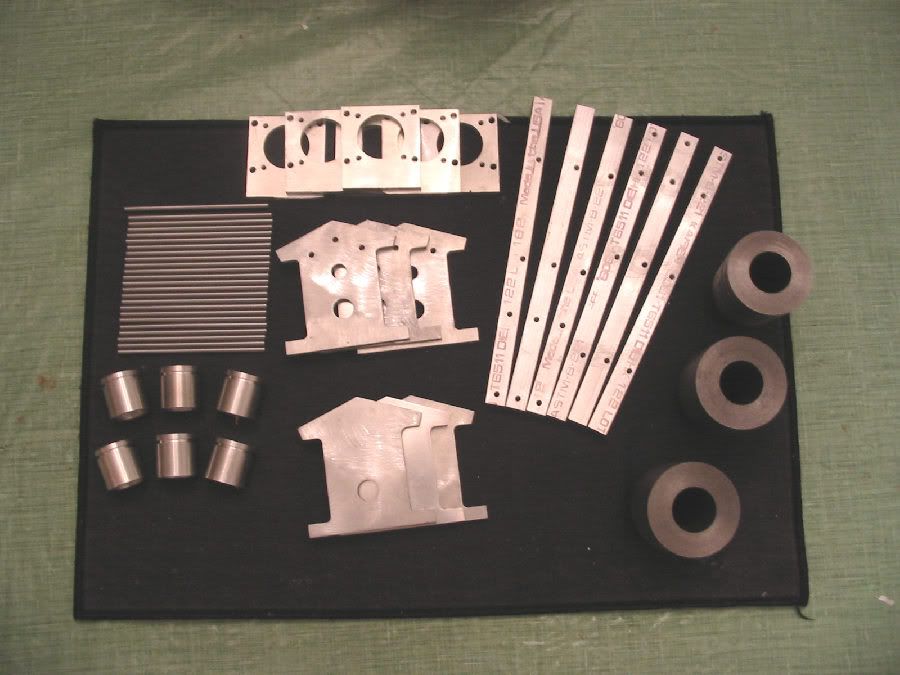

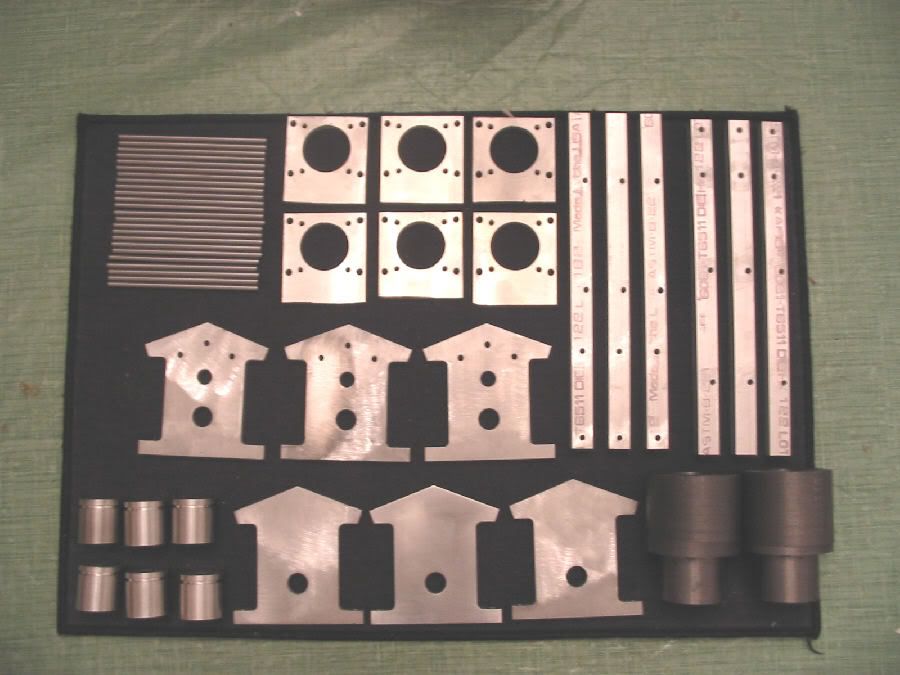

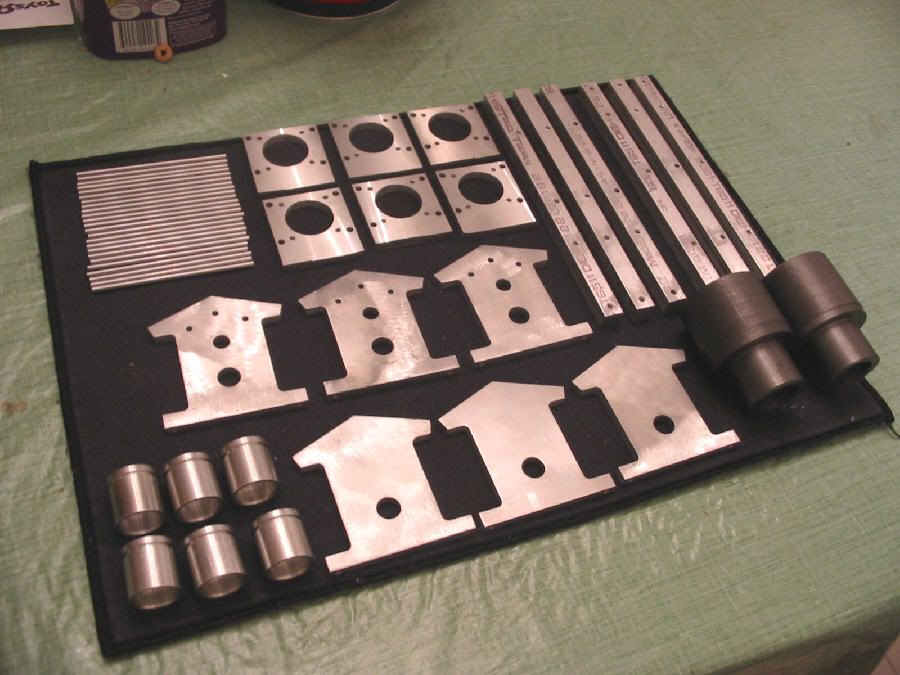

Here is my current main (long term) project. I don't get a lot of time in the shop but here is what I have to far. Some parts shown aren't totally finished and the cylinder with fins is one I'm not using. I'm still learning the art of making properly spaced fins and making the tools to cut them.

I am making 3.

I am making 3.