You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hit me - Miss me?

- Thread starter Maryak

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

steamer said:C.O.R.

translation

Carry On Regardless!..........just making sure your cardiologist understood.... ;D

You bet your lilly white )(*&@& it's going to run! woohoo1

Dave

A couple of things about COR

In Oz it stood for Commonwealth Oil Refineries which were subsequently part of the BP group.

Also there was an Australian whiskey called Corio.............for those who partook, it was known as COR 10 which was a pretty accurate description of taste and lubricity.

Best Regards

Bob

gabby

Well-Known Member

Hi all,

Running is not an option in this case, it's bloody mandatory

Cheers

Graham :big:

Running is not an option in this case, it's bloody mandatory

Cheers

Graham :big:

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

tel said:I remember Corio! Didn't they used top make it out of metho and brown boot polish?

That was the high quality stuff which came with a label and a proper cork IIRCC

Best Regards

Bob

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

I'm with Graham. MANDATORY.

I remember when this thread started.

I want to remember its end.

The end is memorable too.

;D

I remember when this thread started.

I want to remember its end.

The end is memorable too.

;D

gabby

Well-Known Member

I have been following this with a very keen eagerness to see and hear it run.

many thanks for showing us your build and in doing so I for one have learned so much from your very instructive dialog. :bow: :bow: th_confused0052

Cheers

Graham

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Zee and Graham,

Thanks guys for your kind words and support. :bow: :bow:

On Thursday I had a trial assembly and the bad news is :

1. A water leak which I suspect is associated with one of the bottom cylinder mounting bolts.

2. There is more compression after a feed of Brussel Sprouts than the engine has.

I feel the need to remove the valves and cage them.

I hope nobody is holding their breath. :

Best Regards

Bob

Thanks guys for your kind words and support. :bow: :bow:

On Thursday I had a trial assembly and the bad news is :

1. A water leak which I suspect is associated with one of the bottom cylinder mounting bolts.

2. There is more compression after a feed of Brussel Sprouts than the engine has.

I feel the need to remove the valves and cage them.

I hope nobody is holding their breath. :

Best Regards

Bob

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Hi Pete,

Thanks for stopping by and your support. :bow:

Hi Gavin,

I once went for a job interview. About half way through, I realized they were playing with me and just going through the motions IAW departmental policy, and the successful applicant had been preselected. So, when they asked me did I have any questions...........I asked "What performance targets have been set?" "Oh," said the head poobar of the panel, "We don't have targets, we have outcomes." "I'm sure you do," I replied. "But are they desirable outcomes!"

After a hostile glare from the head poobar.............. "Thank you for your time, Bob, we'll be in touch."

Needless to say I did not get the job.

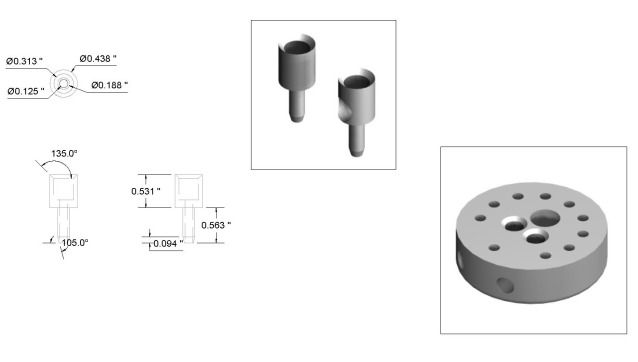

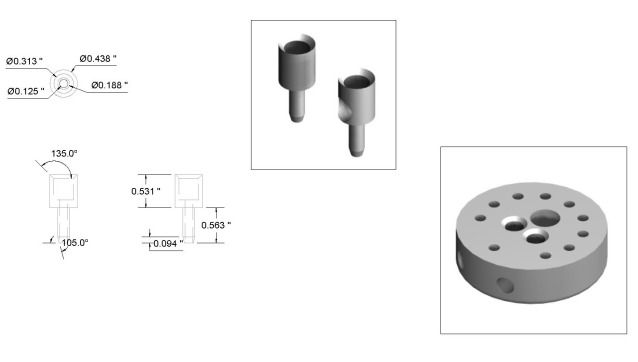

At the moment my opportunity is designing the valve cages with my CAD program.

Best Regards

Bob

Thanks for stopping by and your support. :bow:

gjn said:Bob

You need to learn management-speak, apparently there are no such things as problems, they are opportunities. You just have a few opportunities ::

:

Hi Gavin,

I once went for a job interview. About half way through, I realized they were playing with me and just going through the motions IAW departmental policy, and the successful applicant had been preselected. So, when they asked me did I have any questions...........I asked "What performance targets have been set?" "Oh," said the head poobar of the panel, "We don't have targets, we have outcomes." "I'm sure you do," I replied. "But are they desirable outcomes!"

After a hostile glare from the head poobar.............. "Thank you for your time, Bob, we'll be in touch."

Needless to say I did not get the job.

At the moment my opportunity is designing the valve cages with my CAD program.

Best Regards

Bob

gabby

Well-Known Member

Damn don't ya just hate it when that happens, still, "nothing ventured....." :-\

(but i will steal your cage design if you don't mind Thm

Cheers

Graham ;D

(but i will steal your cage design if you don't mind Thm

Cheers

Graham ;D

Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Gavin and Graham,

Thanks for your continued support. :bow: :bow:

Despite rumours to the contrary, I have not given up I have almost finished my new head job ;D

I have almost finished my new head job ;D

Today I went to get some Loctite 620 for the valve cages. At the moment, brandy in hand, I am reeling from the quoted price, $50 for a small bottle. Needless to say I didn't part with any cash and am meditating on alternatives. It seems that most of the epoxy glues are good for up to 1800 C. But I'm wondering if that is high enough for the exhaust valve. Loctite 620 is rated at 4500 F say 2300 C.

Needless to say I didn't part with any cash and am meditating on alternatives. It seems that most of the epoxy glues are good for up to 1800 C. But I'm wondering if that is high enough for the exhaust valve. Loctite 620 is rated at 4500 F say 2300 C.

Any suggestions would be most welcome.

Best Regards

Bob

Thanks for your continued support. :bow: :bow:

Despite rumours to the contrary, I have not given up

Today I went to get some Loctite 620 for the valve cages. At the moment, brandy in hand, I am reeling from the quoted price, $50 for a small bottle.

Any suggestions would be most welcome.

Best Regards

Bob

gabby

Well-Known Member

Hi ya Bob,

I have an affinity for easy-flo which done carefully and with an even heat distribution, should be more than adequate for your needs and you probably have some just laying around.

You may have to do a little hand lapping to seal the deal so-to-speak, veola, job done.

Cheers

Graham

I have an affinity for easy-flo which done carefully and with an even heat distribution, should be more than adequate for your needs and you probably have some just laying around.

You may have to do a little hand lapping to seal the deal so-to-speak, veola, job done.

Cheers

Graham

Herbiev

Well-Known Member

- Joined

- Jan 6, 2011

- Messages

- 2,360

- Reaction score

- 310

Hi Bob. JB WELD according to their data is often used for repair of engine blocks.

http://www.cotronics.com/vo/cotr/pdf/4700N.pdf is another product available in 10gm kits and is good for 600deg F

Measure-tech in Victoria stock Cotronics products

Best of luck

Herbie

http://www.cotronics.com/vo/cotr/pdf/4700N.pdf is another product available in 10gm kits and is good for 600deg F

Measure-tech in Victoria stock Cotronics products

Best of luck

Herbie

fcheslop

Well-Known Member

Hi Bob,daft question could they not be made a light press fit? then cut

kind regards Frazer

kind regards Frazer

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 19

- Views

- 5K

- Replies

- 13

- Views

- 1K