Xlmyford

Well-Known Member

- Joined

- Mar 8, 2009

- Messages

- 97

- Reaction score

- 4

Hello.

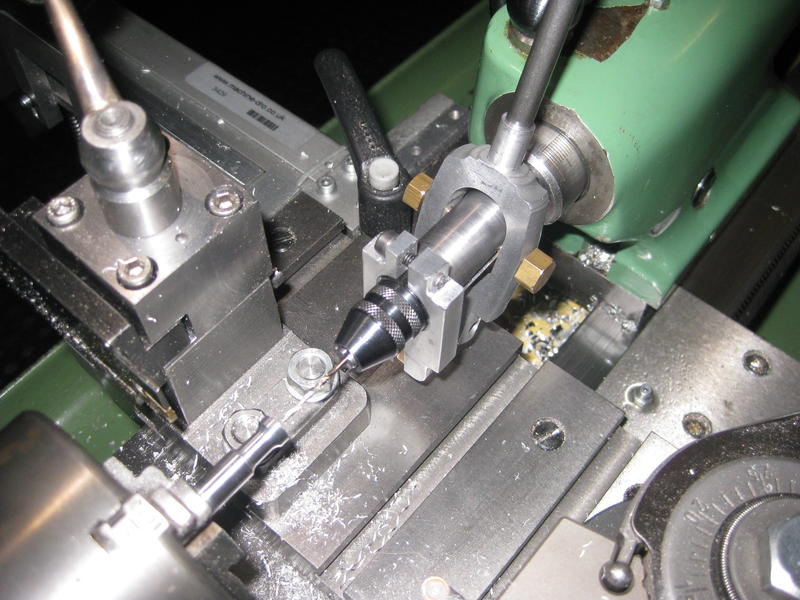

I'd like to show you some helpful gadgets that I made recently.

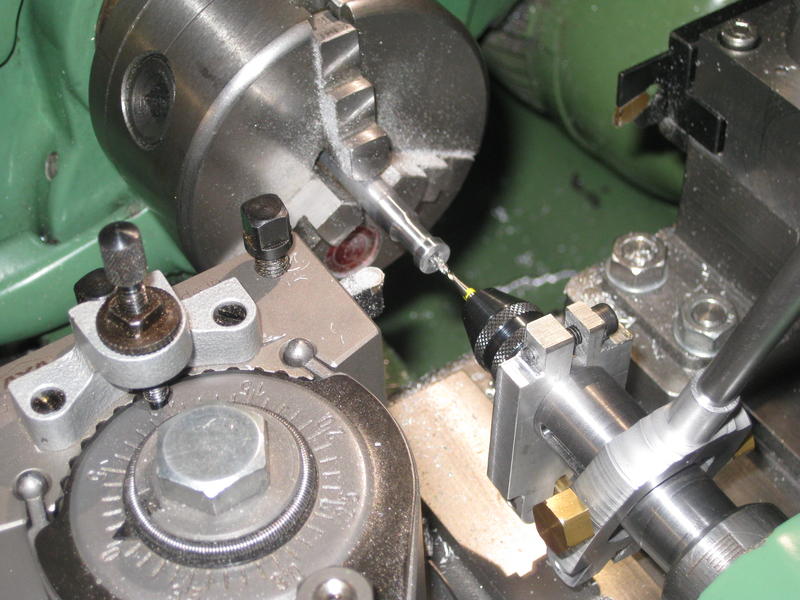

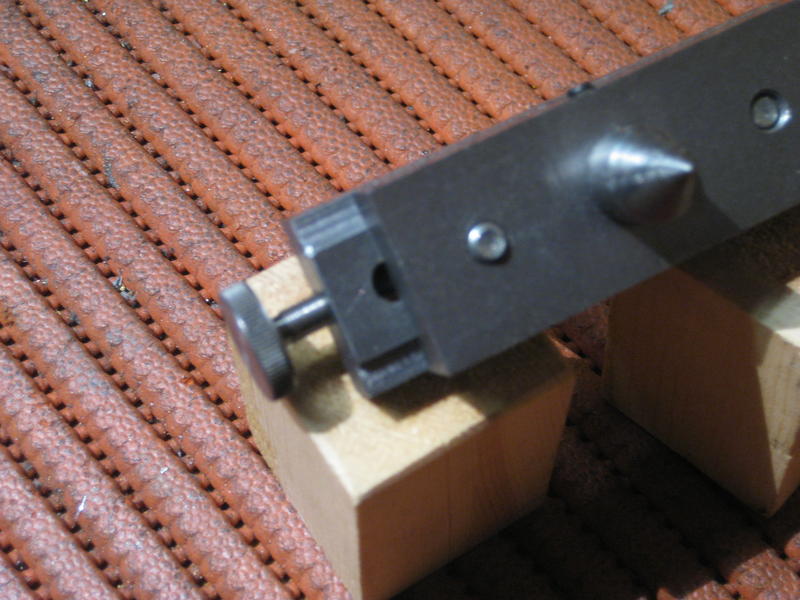

A backstop for my lathe,regarding H.Hall's plans,

http://homews.co.uk/page92.html

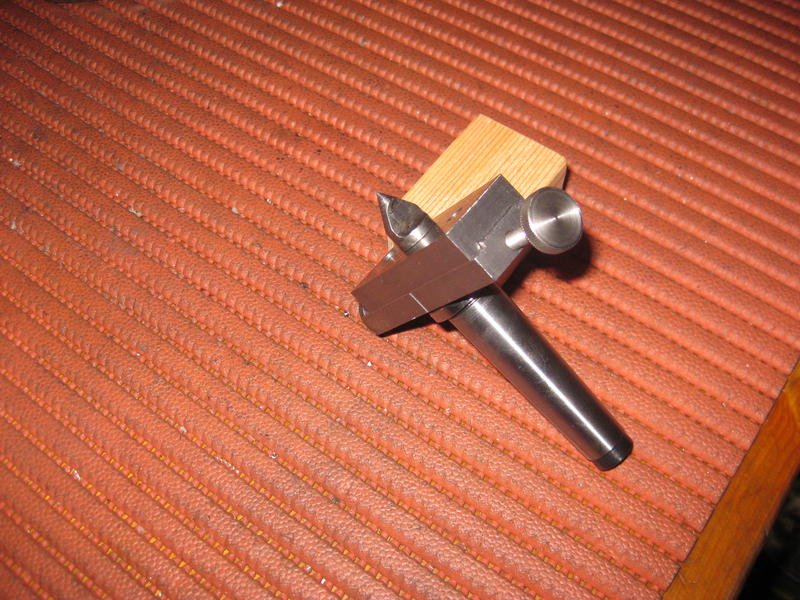

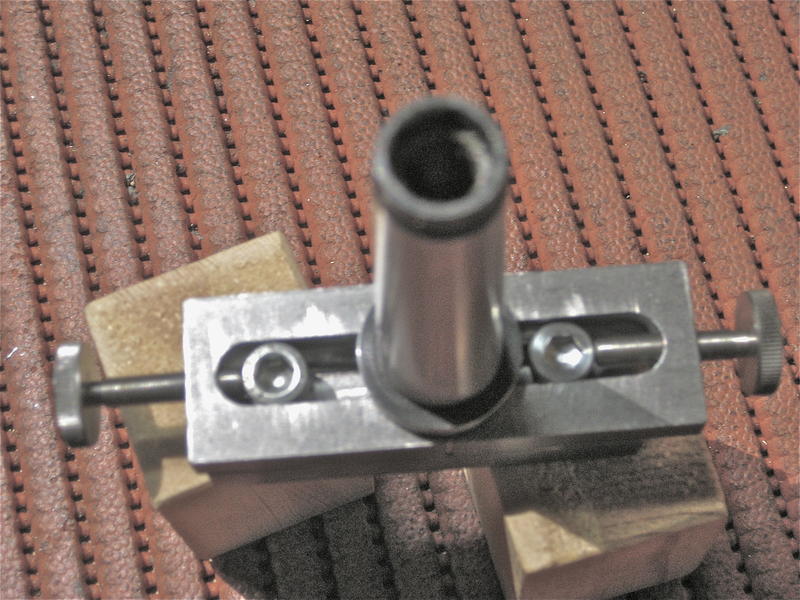

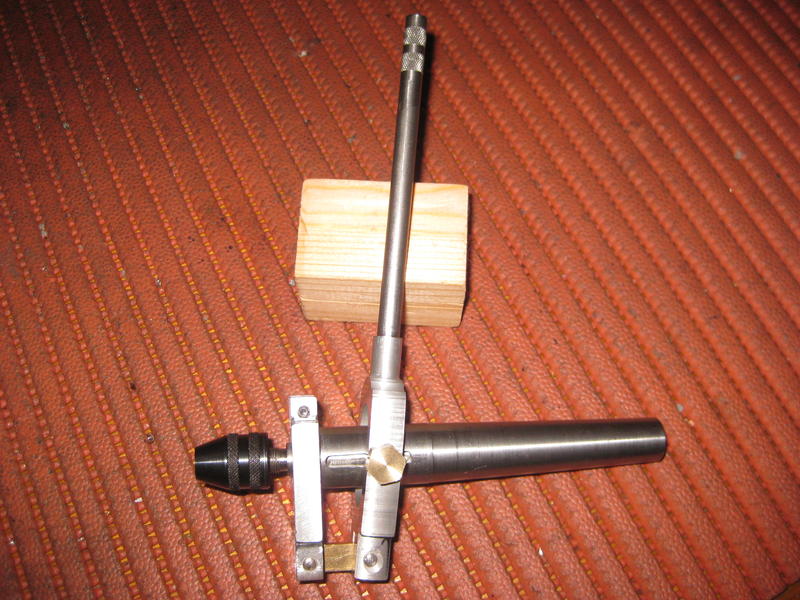

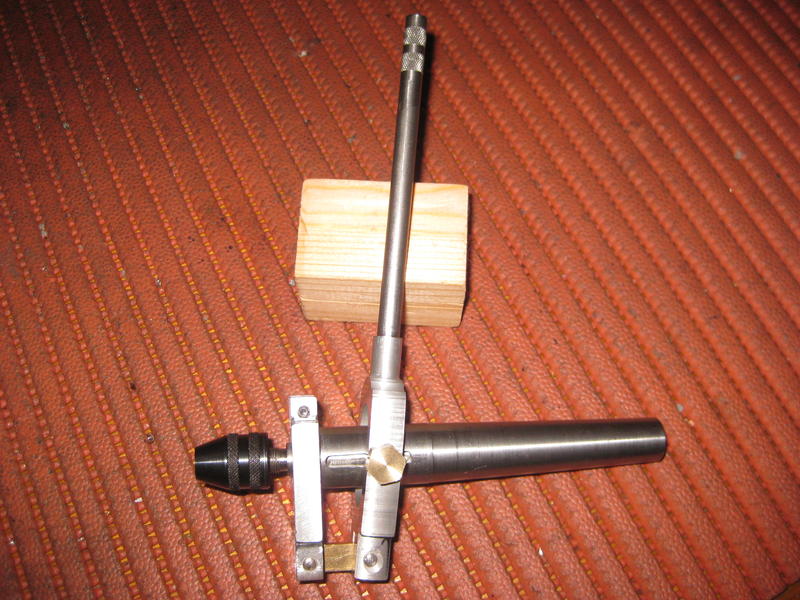

a set over tailstock center from Hemingway Kits

http://www.hemingwaykits.com/acatalog/Set_over_Centre.html,

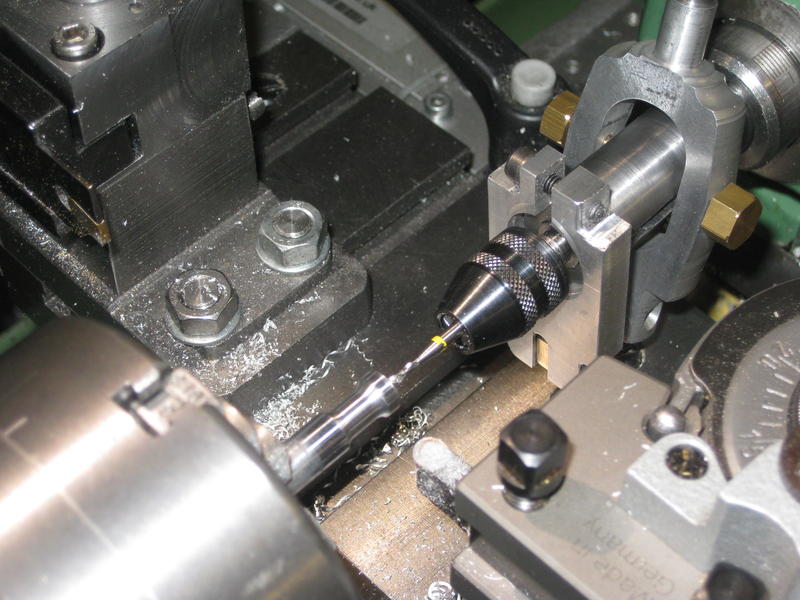

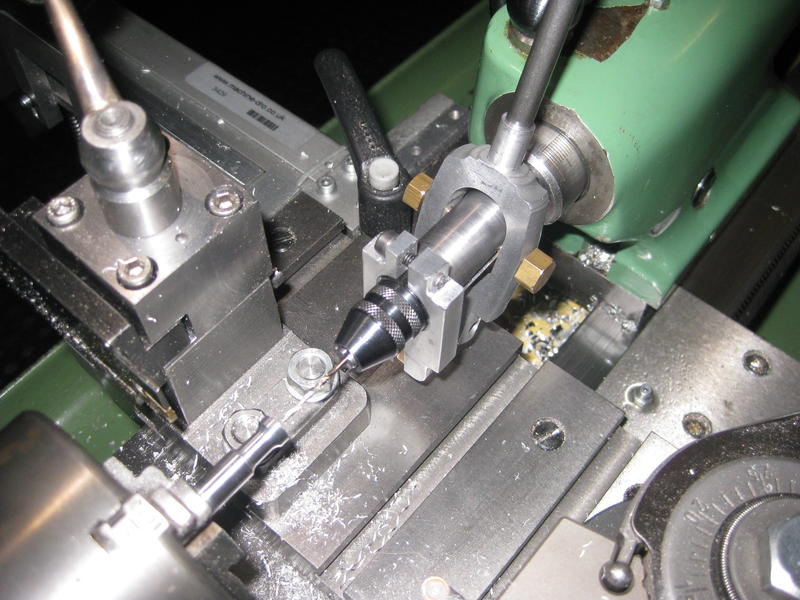

and a lever operated drilling head for the tailstock.It makes it much easier to get rid of the swarf while drilling small holes.

I even made this morse taper myself,using my new fabricated set over center.It worked pretty good.

Today I started a new project in which this drilling head will be of good use.

You can say,one thing leads to another.

Thank You for watching.

Cheers,Ralph

I'd like to show you some helpful gadgets that I made recently.

A backstop for my lathe,regarding H.Hall's plans,

http://homews.co.uk/page92.html

a set over tailstock center from Hemingway Kits

http://www.hemingwaykits.com/acatalog/Set_over_Centre.html,

and a lever operated drilling head for the tailstock.It makes it much easier to get rid of the swarf while drilling small holes.

I even made this morse taper myself,using my new fabricated set over center.It worked pretty good.

Today I started a new project in which this drilling head will be of good use.

You can say,one thing leads to another.

Thank You for watching.

Cheers,Ralph