Allen,

What you have to remember is that I am working from plans and castings, so hopefully all dimensions and working out have been done for me. So don't go putting yourself down because of lack of certain types of education, I am sure that there are many people such as yourself on here who dread it when formulae and working out are quoted. I am one of those at certain levels, but manage to muddle through by asking the right type of questions when required, everyone cannot know everything, that is why we try to help each other.

Now, the unfortunate bit, in your case, certain dimensions have to be worked out, but if working with pencil, paper and ruler, you can usually get close enough by drawing a neat diagram and taking measurements, even having to rub out and try again until you get it right.

You would work backwards, from knowing how much of a flame slot you have to cover, plus a little bit, then how far your cam should be away from the flame slot cover and then where you put in a pivot point you can draw and work things out to close enough.

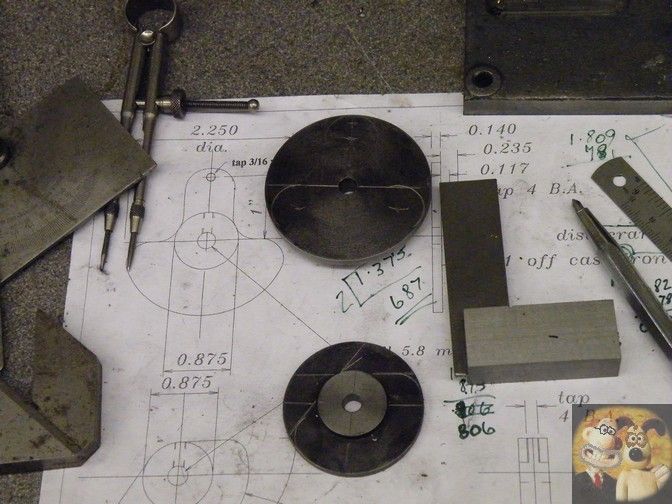

The shape of the cam should be basically as I have shown, just a different 'lift' to make sure, the small diameter is when the flame hole is totally uncovered (on the suck in stroke of the piston) and the larger diameter when the piston is on the vacuum (flame port closed) stroke.

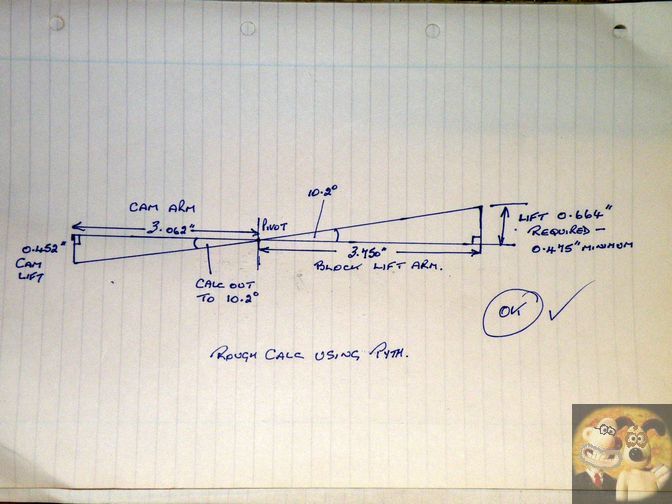

Just to prove that I don't tell lies, here is the proving sketch I did for the Scott engine above, so that I could have the graphite block being lifted up instead of dropping to let the flame in as suggested by the plans and still using the cam I had already made.

Done with paper, pen and ruler and only a tiny bit of basic working out with a calculator or a little desktop engineering calculations program, and I am sure that if you can get the dimensions, someone will step in and work things out for you.

I do hope this doesn't confuse you any further.

John