vascon2196

Well-Known Member

- Joined

- Oct 2, 2009

- Messages

- 1,026

- Reaction score

- 312

Thanks Ross.

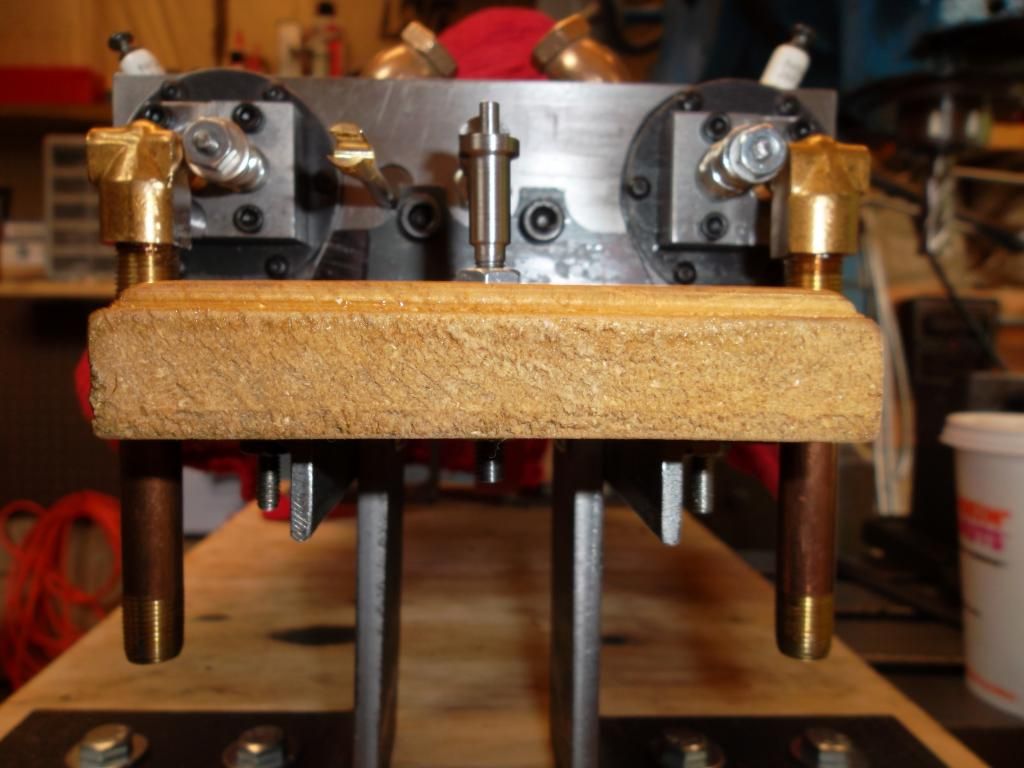

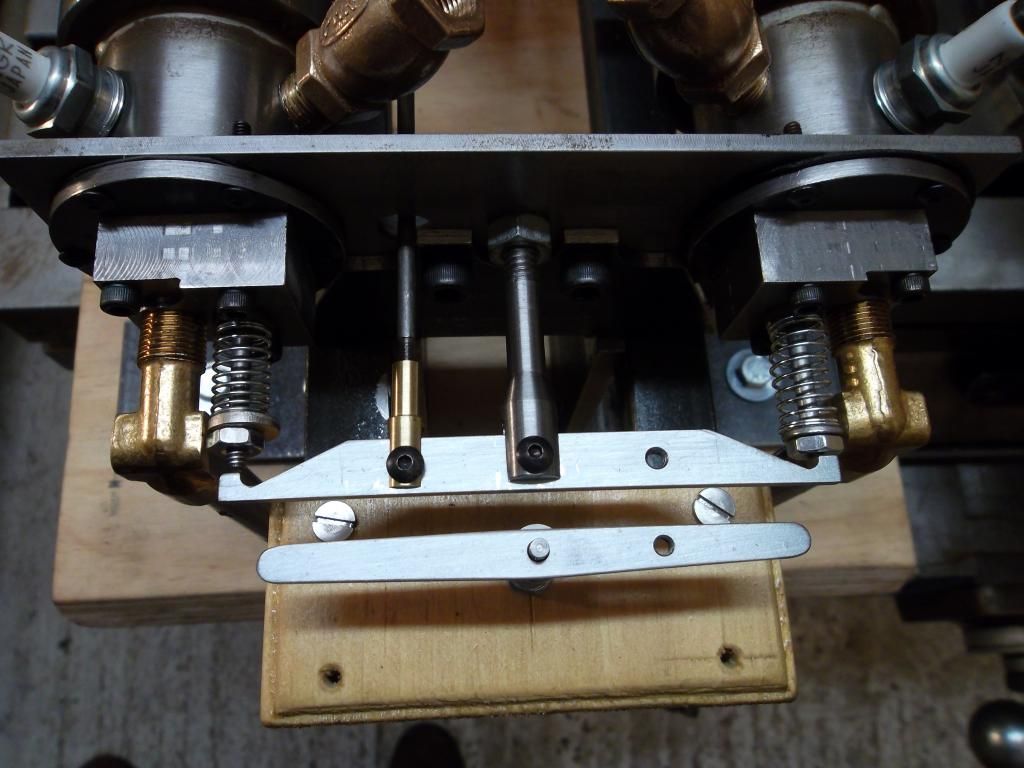

I did not machine the bore...just honed. It was seamless tubing from McMaster Carr, not sure the exact material.

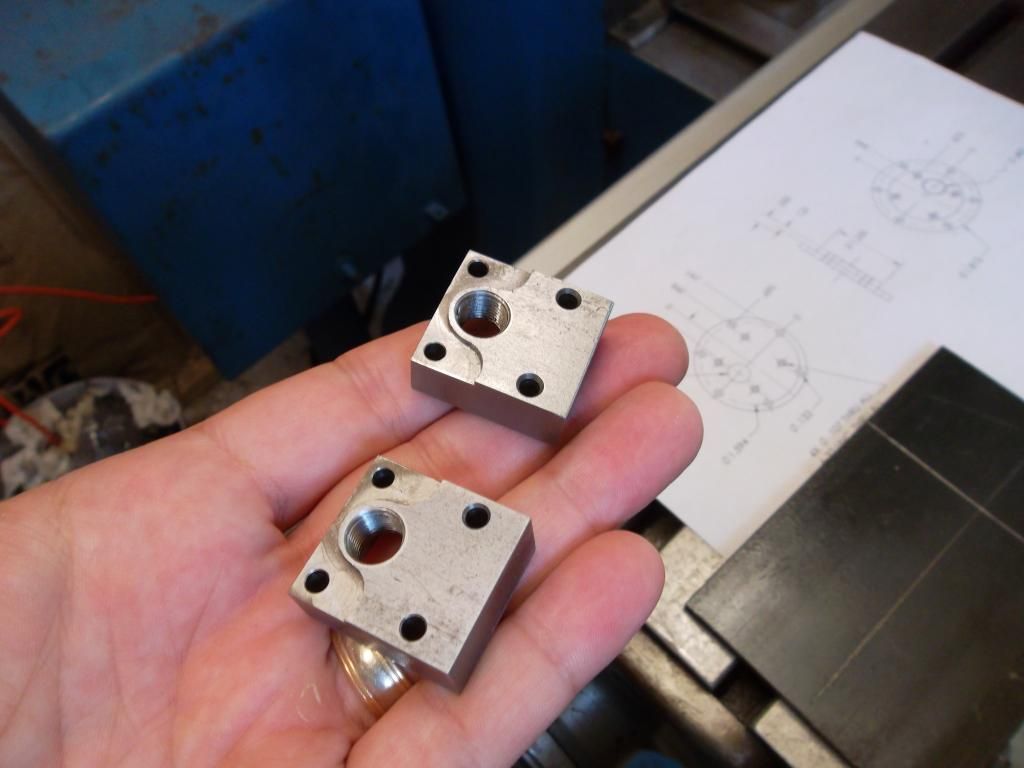

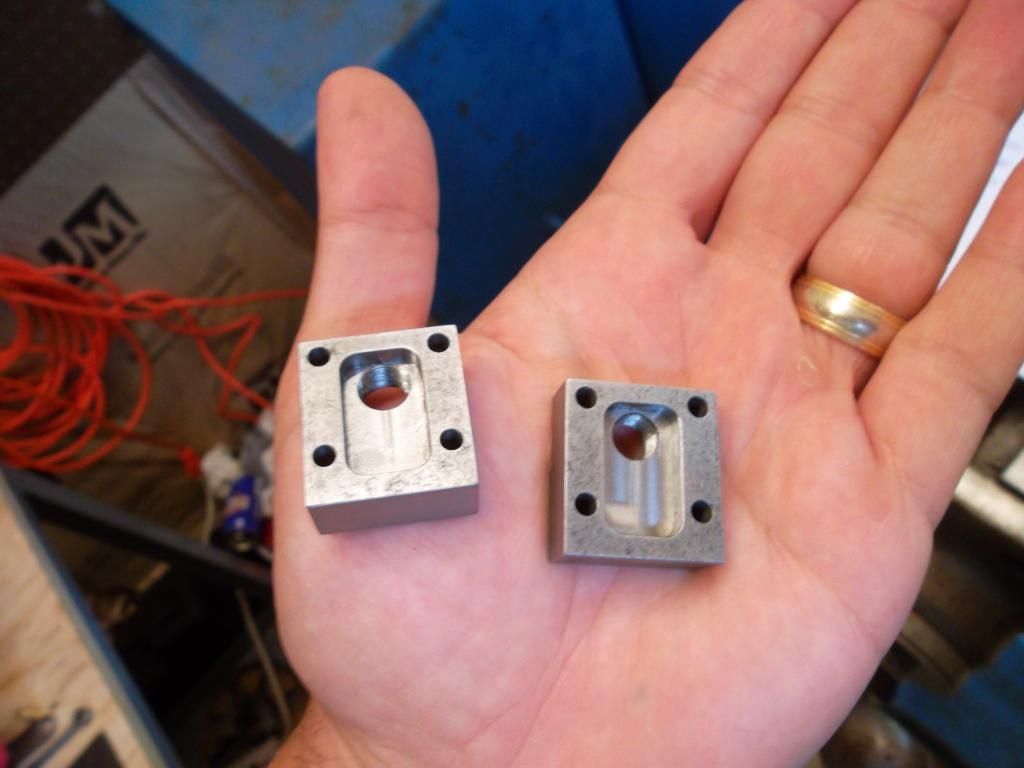

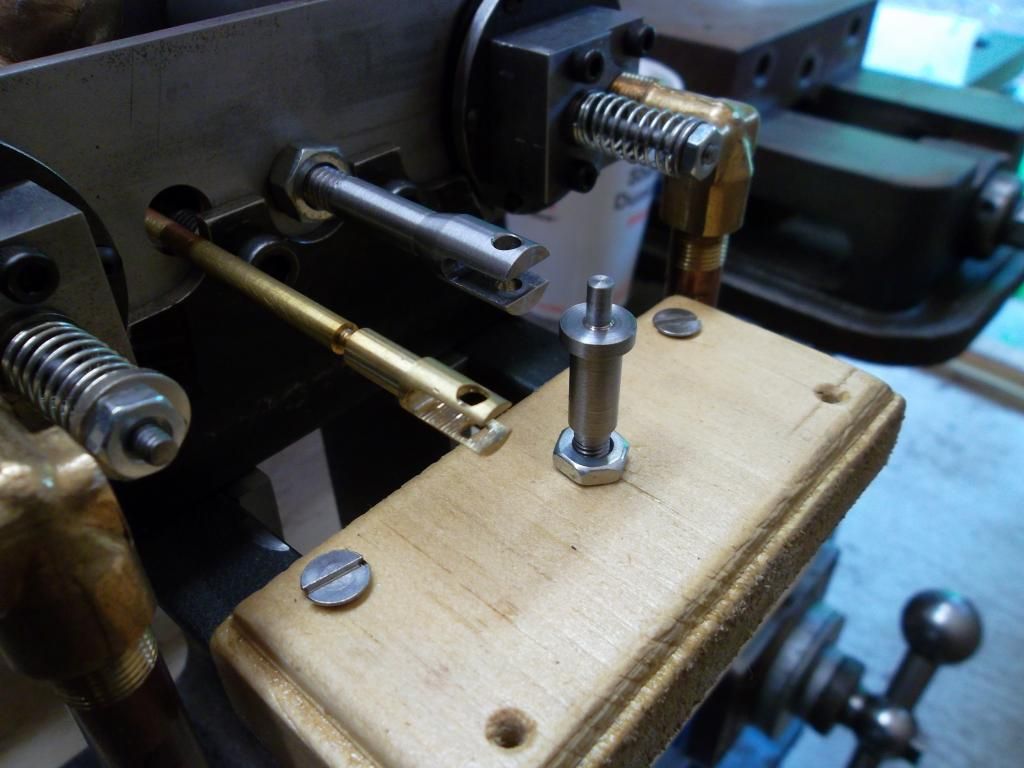

Yes the crank pins are brass...I normally use a shoulder bolt for crank pins but I thought making them from brass would look nice. Do you think they will get too hot? I can add an oiler.

I did not machine the bore...just honed. It was seamless tubing from McMaster Carr, not sure the exact material.

Yes the crank pins are brass...I normally use a shoulder bolt for crank pins but I thought making them from brass would look nice. Do you think they will get too hot? I can add an oiler.